how to become a cnc manufacturer Comprehensive career guide to responsibilities, certifications, career paths and compensation for CNC Machinists in the Manufacturing industry. In most places, they put the connections in a junction box (I corrected one or places where connections (wire nuts) were just dangling in the air). But, in all cases the junction boxes are not covered and are not fastened to anything.

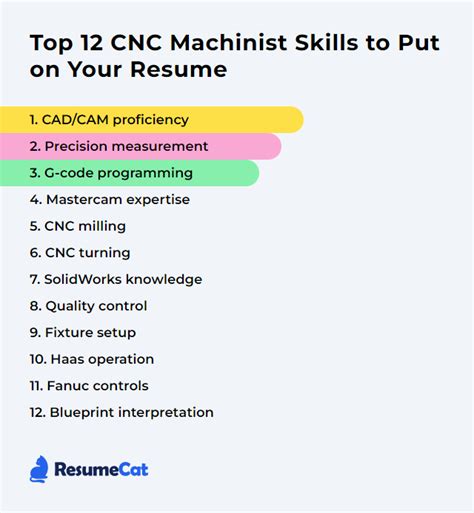

0 · skills for cnc machinist

1 · how to become cnc operator

2 · how to become cnc certified

3 · cnc machinist job requirements

4 · cnc machine basic knowledge

5 · cnc for dummies

6 · cnc for beginners

7 · becoming a cnc machinist

Sheet metal is the preferred material for closure panel applications. From door panels, fenders, roofs, liftgates, and hoods, sheet metal adds both functionality and aesthetic appeal to a vehicle’s design. Its versatility allows for customization options to .

Pursuing a CNC machining program is recommended to improve your skills and knowledge. This training path comprises practical firsthand training and structured classroom lessons, including metalworking, machine tooling, technical . Find out how to become a CNC machinist in six steps, plus learn the required skills, job outlook and average salary for this position.Comprehensive career guide to responsibilities, certifications, career paths and compensation for CNC Machinists in the Manufacturing industry.Educational Pathways to Becoming a CNC Machinist. So, how does one become a CNC machinist? There are several educational pathways available, from technical schools and .

In a straightforward rundown, this article will detail the stepping stones to becoming a CNC machinist, shed light on potential job roles, and examine how to evolve with industry . Steps on How to Become a CNC Machinist. Step 1: Obtain a high school diploma or equivalent. Focus on math, computer science, and shop courses. Step 2: Enroll in a technical .

How To Become a CNC Machinist. The minimum qualification to become a CNC machinist is holding at least a high school diploma, to start with entry-level positions that give training on the job. At an early stage, students should pay .

There are several paths to becoming a CNC machinist. Apprenticeships for CNC machinist certification combine structured education with practical on-the-job training, benefiting both .Explore the steps to become a CNC machinist, including education, training, certifications, and skills required for a successful career in this field.Since every CNC machine is only as good as the expert who powers it, CNC machinists are one of the most important professionals in modern manufacturing. Thanks to them, companies can properly install, maintain, operate, and upgrade their CNC machines to .As a Machinist and Toolmaker of 20 years experience, I’d advise against it. Manufacturing is one of those industries in which customers are always demanding lower prices, which in turn leads to wages being lower than average, despite the tremendous amount of skill required to demand top dollar wages, not to mention the time it takes to learn said skills.

How To Become a CNC Programmer. To become a CNC programmer, an individual must have at least a high school diploma. Entry level career opportunities require candidates to acquire the necessary skills with a few . To become a CNC programmer, you must be proficient in coding, computer-aided design (CAD) software, and computer-aided manufacturing (CAM) software. You must also be familiar with the different types of CNC machines and their applications.Introduction. In today's technologically advanced manufacturing industry, CNC machinists stand out as pivotal players. The role of a CNC (Computer Numerical Control) machinist combines technical know-how with precision engineering to produce a myriad of components critical to various industries, including automotive, aerospace, and medical devices. The terms CNC manufacturing, CNC automation, and CNC machining all allude to the use of Computer Numerical Control (CNC) via programming to increase quality and consistency of the product. . To become a CNC machinist, it’s good to complete a training program in one of the US manufacturing schools, or better still, one of the most reputable .

Overall, CNC machinists play a vital role in the manufacturing industry, contributing their expertise to produce the precision components that form the backbone of modern technology and innovation. . Becoming a CNC machinist involves a structured pathway that starts with obtaining a high school diploma or GED, followed by enrolling in a .

Went to a community college and got a manufacturing machine technology certificate in 2013. Got a job as an operator running robo-drills at an aerospace job in 2014. After a short time, they needed help in turning, so they put me on a CNC VTL and trained me how to set-up.What is a machinist? A machinist works with a variety of machines that are used in manufacturing and production settings. Highly trained machinists will possess a thorough knowledge of the materials and tools for machinist jobs to complete high quality work. They use machines such as CNC, grinders, or milling machines to create precise parts according to detailed instructions.CNC Machining Service. 3DEXPERIENCE Make Online CNC Machining Service | Compare quotes from dozens of manufacturers. . Why become a Manufacturing Partner ? REACH. Dassault Systèmes's extensive user-base from Solidwork to CATIA, Enterprise customers, and other engineers worldwide. Read more: Manufacturing Guide: How to Become a CNC Machinist. Source: Salary.com. The salary range can vary widely depending on many other important factors, including geographical location, education, number and level of certifications, or additional skills, and the number of years a programmer has spent in your profession, says Salary.com .

The CNC Machinist's Role in Manufacturing In this section, we explore the role of a CNC machinist in a CNC Machining manufacturing plant.CNC machinists are responsible for operating computer numeric controlled (CNC) milling machines and lathes. They work with a number of different types of materials, such as metals and.Together we are shaping the future of manufacturing. Become a partner. Additional sales due to higher machine utilization. 100% pre-qualified requests; Free of charge for manufacturing partners ; More orders and additional sales CNC programmers are skilled professionals who play a pivotal role in manufacturing. They use their expertise to program the computer code that controls the operation of computer numerical control (CNC) machines. By doing this, they ensure precision during production. Understanding how to become a CNC programmer can offer insight into whether .Lastly, aspiring CNC machinists in Ohio may also consider the hands-on Machine Tool Technology and CNC Manufacturing program at Ohio State University's College of Engineering. Read more As expected, the program incorporates classroom and hands-on training, dealing with turning, milling, CAM/CAD, and more.

SyncFab supplier partners maximize revenue manufacturing customer orders with minimal overhead to efficiently manage machine capacity. In conclusion, becoming a CNC Machinist in the UK is an excellent career choice for anyone interested in the manufacturing industry. With the right qualifications and skills, you can enjoy job security, excellent pay, and the satisfaction of creating high-quality products that meet the demands of today’s market.

As manufacturing facilities evolve from dangerous factory floors to automated fabrication centers, computer numerically controlled (CNC) machines are the heart of modern manufacturing. From lathes and mills that cut raw materials into usable shapes to 3D printers that create useful designs from bulk materials, CNC machines use computer code to transform .

A CNC machinist is a tech expert who operates, builds and troubleshoots computer-based manufacturing machines, creating final products to meet industry standards. To become a CNC machinist, complete secondary school with maths, English and science; decide the type of machinist to be, undertake relevant degrees or courses, and start with entry .

If you have the money, get a small CNC router and learn how it works. YouTube tutorials are a great start, but if you want to work in the industry having some kind of certification will get you a job much faster. TLDR: Starting CNC machining from scratch is very hard, but so are most jobs.

Been programming and setting up fixed head and sliding headstock CNC turning centers for more than a decade. 24hr lights out unattended production, prototyping, etc. If you're programming or need to adjust programs, learn the g and m codes.I left that company and became a production manager running a cnc shop in the automotive sector. Then a plant manager for 3 different companies. After 10!years of plant management I moved into sales where I learned the commercial side of manufacturing.

In manufacturing, every intricate part, component, and machine is the result of the work of skilled machinists. If you have a passion for problem-solving and a desire to create, then becoming a journeyman machinist might be right for you. Discover the steps to begin and advance a career as a journeyman machinist. What is a journeyman machinist?

decorative punched metal sheets

Becoming a CNC Machinist in Arizona. Future CNC Machinists must complete a series of steps before applying for a job. The steps are laid out below. Step 1 – Education. Some employers will hire people who only finished high school or have a GED. Some CNC machinists choose to enroll in universities and trading schools to earn some credentials. Becoming a CNC machinist and master programmer is a rewarding career path. It requires dedication, continuous learning, and a passion for precision. . Title: Mastering CNC Manufacturing: The Crucial Elements for High-Quality Parts April 9, 2024. Unlocking the Future of Aerospace Manufacturing: Innovative Solutions and TechnologiesTo become the master of your craft, there are certainly costs to becoming a CNC machinist. Those who choose the educational path will pay between ,000 and ,000 depending on the length of the program, grants, certifications, and specialized training. How to Become a CNC Machinist. If you want a career as a CNC machinist, you need to have good theoretical knowledge and practical skills. You can choose to go the formal education route and attend a CNC learning course or get an apprenticeship with a manufacturing company that uses CNC technology.

skills for cnc machinist

how to become cnc operator

This article covers the examples of distribution channels like direct sales and wholesaling, along with their benefits and real-life case studies so you can choose the best ones for your business. Quick Summary. Distribution channels are key to .

how to become a cnc manufacturer|how to become cnc operator