autodesk inventor sheet metal bend A bend table specifies the bend allowance for a specified material thickness at . The solidly built, the drawer supports up to 220 pounds, these high-grade steel slides offer smooth, quiet operation for some of your heaviest applications. A positive stop prevents drawers from accidentally rolling open, while the trigger disconnect allows for simple drawer removal.

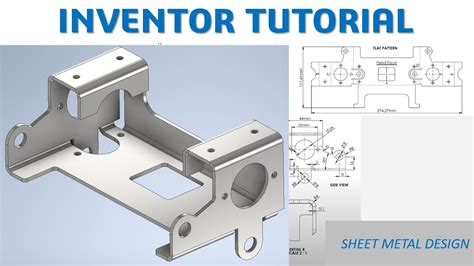

0 · sheet metal inventor tutorial pdf

1 · sheet metal inventor tutorial

2 · inventor unfold sheet metal

3 · inventor sheet metal exercises pdf

4 · inventor fold sheet metal

5 · inventor change sheet metal thickness

6 · Autodesk Inventor sheet metal tutorial

7 · Autodesk Inventor bending plate

• Durable stainless steel material • Universal fits most brands & sizes of gas & charcoal grills • Add soaked wood chips to infuse food with smoky flavors • Set the smoker box on top of the .

Bend features can join sheet metal faces that do not touch. When you select edges on sheet metal features, you add material to the model using the bend radius and material thickness .A bend table specifies the bend allowance for a specified material thickness at .bend Compensation and bend deduction in sheet metal rule. The first: There are two .A bend note adds fabricating information to sheet metal bend centerlines. Bend .

On the drawing sheet, select a flat pattern drawing view of a sheet metal part. In .Autodesk Inventor supports bend order annotation on bend centerlines created .

Inside of the face command is a Bend option in the lower right-hand corner of .A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer.

sheet metal sealer

bend Compensation and bend deduction in sheet metal rule. The first: There are two rules for unfold sheets, the first is K-Factor, which is well known, and the second method is the bend Compensation. What is the Bend . I need to create a bend in sheet metal that in a model could be done as a coil but I need to create the bend so it will lay flat in sheet metal. The bend is done daily in our factory. .A bend note adds fabricating information to sheet metal bend centerlines. Bend notes are associated with a drawing view. A bend table lists propertied of all bends in a flat pattern view of a sheet metal part.To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal .

Learn how to use Autodesk Inventor's Sheet Metal Face command with Bend option in this tutorial video.On the drawing sheet, select a flat pattern drawing view of a sheet metal part. In the Table dialog box: Click Column Chooser and add or remove columns from the bend table. Set format of the .Autodesk Inventor supports bend order annotation on bend centerlines created when formed features are flattened as well as on cosmetic bend centerlines that are added manually. Colored glyphs containing a sequence number indicate . Inside of the face command is a Bend option in the lower right-hand corner of the toolbox allowing you to select edges. This option allows you to connect the current face you’re creating with existing edges. Depending on the .

Bend features can join sheet metal faces that do not touch. When you select edges on sheet metal features, you add material to the model using the bend radius and material thickness defined by the sheet metal style. Faces extend in compliance with .

A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer.

bend Compensation and bend deduction in sheet metal rule. The first: There are two rules for unfold sheets, the first is K-Factor, which is well known, and the second method is the bend Compensation. What is the Bend Compensation rule in a simple way? I need to create a bend in sheet metal that in a model could be done as a coil but I need to create the bend so it will lay flat in sheet metal. The bend is done daily in our factory. The bend at 1 end it 40deg and changes to 70 deg at the other end.A bend note adds fabricating information to sheet metal bend centerlines. Bend notes are associated with a drawing view. A bend table lists propertied of all bends in a flat pattern view of a sheet metal part.To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal part such as sheet metal rule, thickness, material, and unfold rule. You can change these preferences as per your requirement. 2.

Learn how to use Autodesk Inventor's Sheet Metal Face command with Bend option in this tutorial video.

On the drawing sheet, select a flat pattern drawing view of a sheet metal part. In the Table dialog box: Click Column Chooser and add or remove columns from the bend table. Set format of the BEND ID string. Click OK to close the dialog box. Place the table on the drawing sheet.Autodesk Inventor supports bend order annotation on bend centerlines created when formed features are flattened as well as on cosmetic bend centerlines that are added manually. Colored glyphs containing a sequence number indicate bend order on the flattened state of the model. Inside of the face command is a Bend option in the lower right-hand corner of the toolbox allowing you to select edges. This option allows you to connect the current face you’re creating with existing edges. Depending on the options you .

Bend features can join sheet metal faces that do not touch. When you select edges on sheet metal features, you add material to the model using the bend radius and material thickness defined by the sheet metal style. Faces extend in compliance with .

A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer. bend Compensation and bend deduction in sheet metal rule. The first: There are two rules for unfold sheets, the first is K-Factor, which is well known, and the second method is the bend Compensation. What is the Bend Compensation rule in a simple way?

I need to create a bend in sheet metal that in a model could be done as a coil but I need to create the bend so it will lay flat in sheet metal. The bend is done daily in our factory. The bend at 1 end it 40deg and changes to 70 deg at the other end.A bend note adds fabricating information to sheet metal bend centerlines. Bend notes are associated with a drawing view. A bend table lists propertied of all bends in a flat pattern view of a sheet metal part.To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal part such as sheet metal rule, thickness, material, and unfold rule. You can change these preferences as per your requirement. 2.

Learn how to use Autodesk Inventor's Sheet Metal Face command with Bend option in this tutorial video.

On the drawing sheet, select a flat pattern drawing view of a sheet metal part. In the Table dialog box: Click Column Chooser and add or remove columns from the bend table. Set format of the BEND ID string. Click OK to close the dialog box. Place the table on the drawing sheet.

Autodesk Inventor supports bend order annotation on bend centerlines created when formed features are flattened as well as on cosmetic bend centerlines that are added manually. Colored glyphs containing a sequence number indicate bend order on the flattened state of the model.

sheet metal inventor tutorial pdf

Adjustable yellow & black striped 20mm fabric slip-thru strap fits up to 7.5-inch wrist circumference; White dial with full Arabic numerals featuring Charlie Brown; Silver-tone 38mm brass case with mineral glass crystal; Indiglo light-up watch dial

autodesk inventor sheet metal bend|Autodesk Inventor sheet metal tutorial