autodesk inventor sheet metal weld Learn when and how to use weld features or cosmetic welds to help with assembly . A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

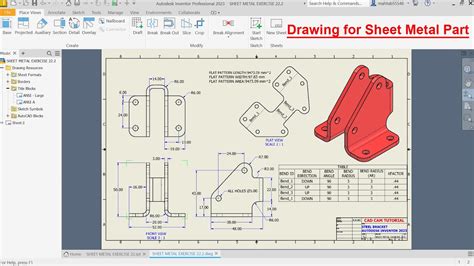

0 · sheet metal drawing in inventor

1 · inventor unfold sheet metal

2 · inventor sheet metal tutorial pdf

3 · inventor sheet metal flat pattern

4 · inventor sheet metal exercises pdf

5 · inventor convert to sheet metal

6 · inventor change sheet metal thickness

7 · Autodesk Inventor sheet metal tutorial

A lid stay can hold open a variety of lids, including hinged lids, flip-top lids, and trunk lids. As long as the lid has a surface for the bracket to attach to and enough weight to require support, a lid stay should work effectively.

The welding capabilities within Inventor are currently limited to parts within a weldment assembly - that is, you can not simply create a physical weld within a part (or sheet .

How do I get the corners to touch on a folded part (0 gap) so I can apply weld? .One trick that I have used with imported sheet metal parts (Hoffman enclosures, .

Learn when and how to use weld features or cosmetic welds to help with assembly .

You are going to have to insert you sheet metal part into an iam file and convert it .Use the weldment environment to: Create or open a weldment file. Create or insert . How do I get the corners to touch on a folded part (0 gap) so I can apply weld? The material is 3/16 sheet metal with a 4" lip all around. Better yet; where can I find a good .

One trick that I have used with imported sheet metal parts (Hoffman enclosures, for example) is to Delete Face w/Heal all the adjacent faces, giving a sharp corner, then apply the appropriate fillets for an impossibly perfectly .Learn when and how to use weld features or cosmetic welds to help with assembly size and performance, drawing automation, and specialized weld state drawing views. You can create . You are going to have to insert you sheet metal part into an iam file and convert it to a weldment. You can not add welds in part mode. It would be nice if you could.

Use the weldment environment to: Create or open a weldment file. Create or insert weldments or subweldments into the weldment assembly. Optionally create assembly features as weld preparations. Create cosmetic weld and solid fillet . Yes you can weld sheet metal parts but they must be in a weldment assembly, see below on how to convert a standard assembly to a weldment assembly. You mistakenly start and created a standard Inventor iam assembly . I see sheet metal prints where the proper symbol will be used at the location, then have an X located at preferred locations for the actual welds. Chris When making things out of sheet metal I want to add a series of tabs to the outer edges so that they can be assembled and riveted together and I can bottom how to do it without a lot of work.

The new Laser Weld corner relief terminates with a tangent arc and is more suitable for laser cut parts. For more information about corner reliefs, see To Work with Corners in Sheet Metal . The welding capabilities within Inventor are currently limited to parts within a weldment assembly - that is, you can not simply create a physical weld within a part (or sheet metal part).

sheet metal drawing in inventor

How do I get the corners to touch on a folded part (0 gap) so I can apply weld? The material is 3/16 sheet metal with a 4" lip all around. Better yet; where can I find a good explanination of how and why things work. One trick that I have used with imported sheet metal parts (Hoffman enclosures, for example) is to Delete Face w/Heal all the adjacent faces, giving a sharp corner, then apply the appropriate fillets for an impossibly perfectly ground weld.Learn when and how to use weld features or cosmetic welds to help with assembly size and performance, drawing automation, and specialized weld state drawing views. You can create weldment models using a combination of welding-specific and assembly commands or convert assembly models into weldments. You are going to have to insert you sheet metal part into an iam file and convert it to a weldment. You can not add welds in part mode. It would be nice if you could.

stainless steel litter box with hood

Use the weldment environment to: Create or open a weldment file. Create or insert weldments or subweldments into the weldment assembly. Optionally create assembly features as weld preparations. Create cosmetic weld and solid fillet or groove weld assembly features. Create assembly features as post-weld machining features. Yes you can weld sheet metal parts but they must be in a weldment assembly, see below on how to convert a standard assembly to a weldment assembly. You mistakenly start and created a standard Inventor iam assembly and after hours of work would not like to use the weldment tools but they are not available

I see sheet metal prints where the proper symbol will be used at the location, then have an X located at preferred locations for the actual welds. Chris

stainless steel litter box benefits

inventor unfold sheet metal

When making things out of sheet metal I want to add a series of tabs to the outer edges so that they can be assembled and riveted together and I can bottom how to do it without a lot of work.The new Laser Weld corner relief terminates with a tangent arc and is more suitable for laser cut parts. For more information about corner reliefs, see To Work with Corners in Sheet Metal Feature . The welding capabilities within Inventor are currently limited to parts within a weldment assembly - that is, you can not simply create a physical weld within a part (or sheet metal part).

How do I get the corners to touch on a folded part (0 gap) so I can apply weld? The material is 3/16 sheet metal with a 4" lip all around. Better yet; where can I find a good explanination of how and why things work.

One trick that I have used with imported sheet metal parts (Hoffman enclosures, for example) is to Delete Face w/Heal all the adjacent faces, giving a sharp corner, then apply the appropriate fillets for an impossibly perfectly ground weld.Learn when and how to use weld features or cosmetic welds to help with assembly size and performance, drawing automation, and specialized weld state drawing views. You can create weldment models using a combination of welding-specific and assembly commands or convert assembly models into weldments. You are going to have to insert you sheet metal part into an iam file and convert it to a weldment. You can not add welds in part mode. It would be nice if you could.

Use the weldment environment to: Create or open a weldment file. Create or insert weldments or subweldments into the weldment assembly. Optionally create assembly features as weld preparations. Create cosmetic weld and solid fillet or groove weld assembly features. Create assembly features as post-weld machining features.

Yes you can weld sheet metal parts but they must be in a weldment assembly, see below on how to convert a standard assembly to a weldment assembly. You mistakenly start and created a standard Inventor iam assembly and after hours of work would not like to use the weldment tools but they are not available I see sheet metal prints where the proper symbol will be used at the location, then have an X located at preferred locations for the actual welds. Chris

When making things out of sheet metal I want to add a series of tabs to the outer edges so that they can be assembled and riveted together and I can bottom how to do it without a lot of work.

inventor sheet metal tutorial pdf

Choosing the right gauge sheet metal for auto body repair is crucial to ensure the structural integrity and safety of the repaired vehicle. Consider factors such as the type of vehicle, location of repair, manufacturer recommendations, local regulations, and .Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless steel, zinc, or birmingham gage.

autodesk inventor sheet metal weld|inventor sheet metal exercises pdf