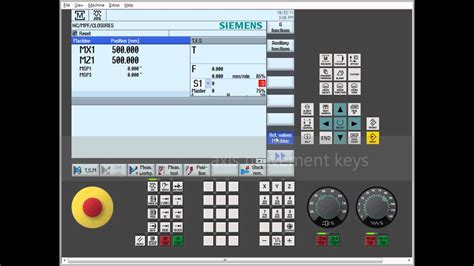

siemens cnc machine CNC Milling - Siemens US. From 3-axis and 5-axis simultaneous to multitasking . It's made of some kind of metal (hard to tell with a fair amount of earth still covering it). It seems flat on the top and no apparent pipes so far. I was thinking it might be an old buried fuel oil container, but from what I've researched its fairly small for that. Any ideas?

0 · sinumerik 840d software free download

1 · siemens machine tool systems

2 · siemens cnc technical support

3 · siemens cnc system

4 · siemens cnc software

5 · siemens cnc programming software

6 · siemens cnc controls

7 · siemens 840dsl toolbox download

When considering the purchase of a CNC mill or router for a small business, it is essential to identify the specific needs of your operations. Key factors to consider include the type of materials you plan on working with, the precision required, the volume of production, and budget constraints.

SINUMERIK – the CNC portfolio for the world of machine tools. SINUMERIK CNC controllers offer the suitable automation solution for all machine designs – for jobshop, contract manufacturing, .Operate CNC machines at maximum performance? Optimize CNC job .SINUMERIK is the perfect automation CNC system for machine tools - from Job .CNC Milling - Siemens US. From 3-axis and 5-axis simultaneous to multitasking .

SinuTrain is our control-identical NC-programming station that’s the ideal tool .SINUMERIK — the CNC portfolio for the machine tool industry. SINUMERIK .SINUMERIK CNC solutions provide companies operating machine tools with .Highly productive automation solutions are demanded for workshops, jobshops and .

SINUMERIK supports multiple machining technologies, from milling, turning and .Operate CNC machines at maximum performance? Optimize CNC job preparation and automate production? Network machines and use the machine tool process data to boost manufacturing .

sinumerik 840d software free download

SINUMERIK is the perfect automation CNC system for machine tools - from Job-Shop manufacturing through large series production. SINUMERIK combines automation, technology knowhow and digitalization to form a unique range of .CNC Milling - Siemens US. From 3-axis and 5-axis simultaneous to multitasking machining. Milling expertise for short machining times and perfect surfaces, SINUMERIK MDynamics has been enhanced with the optional technology .SinuTrain is our control-identical NC-programming station that’s the ideal tool for offline programming and even professional learning. Not only is it used in manufacturing, but also in .SINUMERIK — the CNC portfolio for the machine tool industry. SINUMERIK controls offer the perfect solution for each and every machine design. No matter if you're manufacturing .

SINUMERIK CNC solutions provide companies operating machine tools with optimum solutions to address specific requirements – whether for individual parts or mass production – basic or . Highly productive automation solutions are demanded for workshops, jobshops and large series production – that accompany and support users along the path to digitalization. .

CNC Grinding - Siemens US. SINUMERIK – Premium choice for the world of grinding. CNC onboard resources and system openness stand for flexible adaptability: Grinding covers an .SINUMERIK supports multiple machining technologies, from milling, turning and grinding through to multitasking, robotics and additive manufacturing.5 SINUMERIK Gcode & Mcodes on Turning Miscellaneous functions / M codes M - code is Machine language code to activate miscellaneous functions. M stands for ‘Machine codes’.This code is used for non-geometry machine functions like coolant on/off,

SINUMERIK 808D ADVANCED brings impetus into basic turning and milling machines. CNCs from the global technology leader, teamed-up with a revolutionary operating concept make the SINUMERIK 808D ADVANCED the perfect entry into the world of CNC.In the course of digitalizatizon, robots and machine tools are increasingly collaborating. SINUMERIK Run MyRobot provides the right solutions – from simple connections, to the convenient integration for handling tasks, through full system integration of the robot kinematics.SINUMERIK 840D sl is considered to be the standard in the premium class CNCs, which is certainly justified. Maximum CNC performance, along with a high degree of flexibility and openness represent the basis for almost every machine concept. A high-performance hardware architecture and intelligent control algorithms as well as premium class drive and motor .

We do manufacturing of new CNC turning machines, all kinds of CNC retrofits with Siemens systems, CNC Panel Building, Commissioning, Laser Calibration and system up gradation. We can celebrate accomplishment, but after a while, we need to start celebrating the speed at which we're travelling instead of destination we've reached.CNC onboard resources and system openness stand for flexible adaptability: Grinding covers an almost infinite range of different applications. SINUMERIK complies with the very specific requirements of these applications with powerful CNC functions and with system openness for CNC operating concepts that can be flexibly adapted.

siemens machine tool systems

Cutting-edge operation, unique technology cycles, ultimate shopfloor programming and high-quality CNC simulation, combined in single expert SINUMERIK. Milling expertise for short machining times and perfect surfaces, SINUMERIK MDynamics has been enhanced with the optional technology functions Top Surface and Top Speed, as well as Intelligent .

SINUMERIK ONE, the digital native CNC, brings your ideas to life. SINUMERIK ONE is the leading-edge CNC system for highly productive machine tools. For unprecedented new opportunities, ideas and business models. For faster innovation based on the seamless interaction of the virtual and real worlds.

IndustryArena Forum > Machine Controllers Software and Solutions > SIEMENS Sinumerik CNC controls > SIEMENS -> Sinumerik 802D/808D/810D/828D/840D > read off machine time Thread: read off machine timesiemens.com. Xcelerator Marketplace. Products & Solutions; Industries; Topics; Ecosystem; API World; Community; Learning Hub; The SINUMERIK Story – Innovation since 1960. 2020 is an ideal moment to look back on 60 years of success. And introduce you to people who share their personal past, present and future with SINUMERIK.Integrating the Siemens SINUMERIK ONE CNC with our production machines marks a significant milestone in our collaboration with Siemens, a global leader in automation and digitalization solutions. SINUMERIK ONE represents the pinnacle of CNC technology in production applications, offering unparalleled performance, precision, and versatility.Are you prepared for the enormous challenges in CNC manufacturing of tomorrow? But what do these mean for each individual and for the learning culture in your company? SITRAIN supports you with a sustainable SINUMERIK learning offer in various and innovative learning formats and thus brings together the needs of learners and the demands of .

However, slotting can also be carried out cost-effectively on CNC turning machines without special components. Special processes such as broaching and slotting are usually used when manufacturing inner and outer profiles. However, slotting can also be carried out cost-effectively on CNC turning machines without special components .

The control identical programming station for production planning, CNC program creation, and training.With its unique CNC performance, our SINUMERIK 828D control sets productivity benchmarks when it comes to milling and turning on standard machines as well as functions to simply automate grinding machines. With new SINAMICS drives and SIMOTICS motion control motors SINUMERIK 828D is now even more productive.CNC from the global technology leader added to a revolutionary operating concept make the SINUMERIK 808 the perfect entry into the world of CNC. For basic turning & milling, Siemens combines global CNC leadership with a .

Here you can read current articles from our CNC4you magazine and other specialist media. Siemens Industry Catalog - Market-specific solutions - Machine and Plant Construction - Machine Tools - SINUMERIK ONE - SINUMERIK CNC - Glossary SINUMERIK ONE - Monitoring functions - Position monitoring. Login Registration. As an already registered user simply enter your userame and password in the login page in the appropriate fields. .

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products . Programmers and operators of turning machines Programming and Operating Manual (Milling) Programmers and operators of milling machines Programming and Operating Manual (ISO Turning/Milling) Programmers and .You can achieve these goals with Siemens’ powerful adaptive control technology – the “original” adaptive control in wide use in metal-cutting industry for almost 30 years. Higher productivity and process stability with Adaptive Control & Monitoring suite (ACM): Increase your productivity, reduce scrap, increase process stability and .One prerequisite for this is suitable turning machines and tools, as well as a CNC control system that supports synchronous spindle coupling. Polygon turning is becoming more and more common in high-output series production of flats. One prerequisite for this is suitable turning machines and tools, as well as a CNC control system that supports .Siemens is one of the world’s leading suppliers of CNC systems, solutions and digitalization services to the machine tool market. With more than 20,000 people in factories, R&D, sales offices and service sites worldwide, we’re shaping the digital transformation of our customers — no matter their industry.

With its unique CNC performance, the Siemens SINUMERIK 828 control sets productivity benchmarks when it comes to milling and turning on standard machines, as well as functions to simply automate grinding machines. With new SINAMICS drives and SIMOTICS motion control motors SINUMERIK 828D is now even more productive.Das CNC-Portfolio für die globale Werkzeugmaschinenwelt. SINUMERIK CNC controllers offer the suitable automation solution for all machine designs – for jobshop, contract manufacturing, and large series production.New requirements regarding superior quality and flexibility affect grinding machine applications more and more . The aim is to increase productivity, even while machining complexity is increasing. With more grinding-related experience the world over, SINUMERIK CNC systems address these industry changes at an unprecedented level. Siemens Industry Catalog - Market-specific solutions - Machine and Plant Construction - Machine Tools - SINUMERIK ONE - Machine Operation - SINUMERIK Machining Performance - Greater precision through the reduction of mechanical deviations - Volumetric Compensation System (VCS)

siemens cnc technical support

siemens cnc system

An electrical junction box helps prevent an electrical fire by reducing the risk of accidental wire damage and shielding connections from harsh environmental conditions. You can further enhance the safety by taking the following precautions:

siemens cnc machine|siemens cnc programming software