capabilities and application of cnc machine In this comprehensive guide, we’ll dive into the world of CNC machines, exploring their evolution, applications, benefits, challenges, and future trends. 1. Definition of CNC Machines. CNC, or Computer Numerical Control, . Vacuum tables are a powerful tool on a CNC machine, offering dozens of advantages that benefit users of all levels. For the new user, a vacuum table is easy, forgiving, and a fast method to .

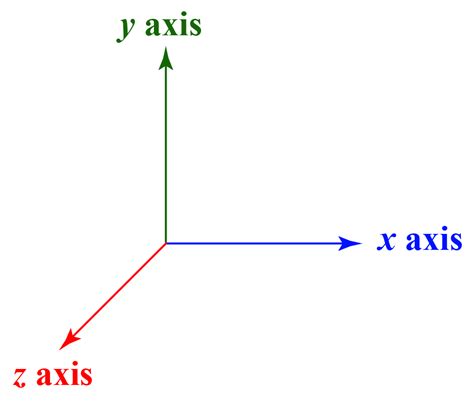

0 · how many axis are there

1 · how does cnc machine work

2 · high end cnc machines

3 · cnc mill axis diagram

4 · cnc machining guide

5 · cnc machine how it works

6 · cnc machine advantages and disadvantages

7 · 5 axis vs 6 cnc

Unlock the full potential of your manufacturing processes with our comprehensive guide to sheet metal fabrication. Dive into the details of transforming flat metal sheets into high-quality, functional parts and products.

Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering.Computer Numerical Control (CNC) cutting offers unmatched accuracy, adaptability, .

In this comprehensive guide, we’ll dive into the world of CNC machines, exploring their evolution, applications, benefits, challenges, and future trends. 1. Definition of CNC Machines. CNC, or Computer Numerical Control, . Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC .

Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for . Key features include multi-axis capabilities, enabling intricate 3D cuts and shapes; tool changers for seamless switching between operations; and advanced control systems that interpret CAD/CAM designs into precise .

CNC machines are automated tools controlled by computer programs that guide the machine's movements to create precise parts and components. These machines are used in a wide .

CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a . Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering.

how many axis are there

12 ga sheet metal price

In this comprehensive guide, we’ll dive into the world of CNC machines, exploring their evolution, applications, benefits, challenges, and future trends. 1. Definition of CNC Machines. CNC, or Computer Numerical Control, refers to the automated control of machining tools and 3D printers by means of a computer. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them. Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for innovative solutions across industries. Key features include multi-axis capabilities, enabling intricate 3D cuts and shapes; tool changers for seamless switching between operations; and advanced control systems that interpret CAD/CAM designs into precise machine movements. CNC machines also boast high-speed machining capabilities, reducing production time while maintaining accuracy.

CNC machines are automated tools controlled by computer programs that guide the machine's movements to create precise parts and components. These machines are used in a wide range of industries, each with unique requirements and applications.CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a vertical milling machine is perpendicular to the worktable. It is designed for machining small components, such as molds, fixtures, and precision parts.

12 sheet metal shear

Let’s navigate through the different types of CNC machining and uncover the unique attributes and applications of each. Milling: Milling machines use rotary cutters to remove material. They’re versatile and can produce everything from simple shapes to complex geometries. Computer Numerical Control (CNC) cutting offers unmatched accuracy, adaptability, and productivity in manufacturing. From complex aerospace parts to custom-made furniture, its applications are broad. Let's delve into CNC cutting and examine its application across multiple sectors. How Big Is the CNC Machining Industry? Explore cutting-edge CNC machine capabilities and their wide range of applications. Achieve exceptional quality and efficiency with precise engineering. In this comprehensive guide, we’ll dive into the world of CNC machines, exploring their evolution, applications, benefits, challenges, and future trends. 1. Definition of CNC Machines. CNC, or Computer Numerical Control, refers to the automated control of machining tools and 3D printers by means of a computer.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.

Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for innovative solutions across industries. Key features include multi-axis capabilities, enabling intricate 3D cuts and shapes; tool changers for seamless switching between operations; and advanced control systems that interpret CAD/CAM designs into precise machine movements. CNC machines also boast high-speed machining capabilities, reducing production time while maintaining accuracy.CNC machines are automated tools controlled by computer programs that guide the machine's movements to create precise parts and components. These machines are used in a wide range of industries, each with unique requirements and applications.

CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a vertical milling machine is perpendicular to the worktable. It is designed for machining small components, such as molds, fixtures, and precision parts.Let’s navigate through the different types of CNC machining and uncover the unique attributes and applications of each. Milling: Milling machines use rotary cutters to remove material. They’re versatile and can produce everything from simple shapes to complex geometries.

how does cnc machine work

12 sheet metal screw drill size

A good printing solution can maximize the value of product printed. As a leading .

capabilities and application of cnc machine|5 axis vs 6 cnc