cnc machine integration Machine integration is the process of collecting, processing, and standardizing data from manufacturing equipment and connecting it to shop floor systems, such as an MES or ERP. Integrating equipment combines the . Solenoid Valve Boxes are designed to give a sophisticated front appearance and a spacious internal layout to facilitate easy maintenance. A console can be provided as an integral part in both simplex and duplex design of the control panel.Discover the VERSA stainless steel junction box – an innovative solution for effortless installation of solenoid valves, switches, indicators, and electronic devices.

0 · machine metrics integration platform

1 · machine metrics integration

2 · machine integration tools

3 · machine integration software

4 · machine integration process

5 · machine integration in manufacturing

6 · machine integration definition

Learn how to properly adjust an off-centered bathroom vanity light and maintain symmetry and balance in your bathroom design. Follow these step-by-step instructions to ensure your vanity light is installed correctly and aligned with your mirror and sink.

CNC machines have been a staple of manufacturers but they are now being paired with automation systems and simulation software to . Machine integration is the process of collecting, processing, and standardizing data from manufacturing equipment and connecting it to shop floor systems, such as an MES or ERP. Integrating equipment combines the .

CNC allows operators to program specific machining operations into machine tools. Using computers to direct the tools provides higher levels of precision and accuracy than manual controls, but even more importantly, it .

The integration of robotic systems with used CNC machines has become a key strategy for improving automation and productivity in the ever changing landscape of .2020 Insight integrates CNC technology by generating and distributing CNC programs for any machine—including integrated machine lines, point-to-points, routers, edgebanders and panel saws—and eliminates the need for manual .

The integration of IIoT technology with CNC machines begins with data collection. MachineMetrics connects directly to the machine control for deep machine connectivity. Note: We also connect to legacy assets to ensure that .The integration of IoT with CNC machines is transforming manufacturing workflows. Data-driven insights enable more agile production methods, rapid prototyping, and dynamic response to market demands. The traditional linear .

machine metrics integration platform

Automation in CNC (Computer Numerical Control) machining refers to the integration of advanced technologies that enable machines to operate with minimal human intervention. This .

The following Section of the presented work describes the development of an information integration procedure for CNC machines, using OPC UA as the foundational technology, thus providing machines with a standardized interface for further uses in Smart Factory environments. CNC machines have been a staple of manufacturers but they are now being paired with automation systems and simulation software to increase production.

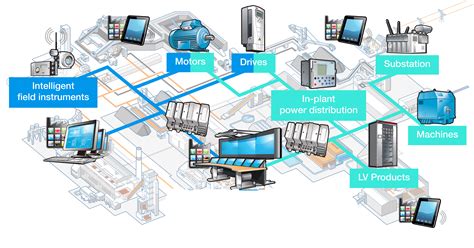

Machine integration is the process of collecting, processing, and standardizing data from manufacturing equipment and connecting it to shop floor systems, such as an MES or ERP. Integrating equipment combines the benefits of real-time data collection and analytical capability with critical enterprise software.

CNC allows operators to program specific machining operations into machine tools. Using computers to direct the tools provides higher levels of precision and accuracy than manual controls, but even more importantly, it provides an element of automation.

machine metrics integration

The integration of robotic systems with used CNC machines has become a key strategy for improving automation and productivity in the ever changing landscape of manufacturing. In this article, we explore the intricacies and advantages of robotics and used CNC machinery working together, offering a complete guide for manufacturers who want to improve .

2020 Insight integrates CNC technology by generating and distributing CNC programs for any machine—including integrated machine lines, point-to-points, routers, edgebanders and panel saws—and eliminates the need for manual programming. The integration of IIoT technology with CNC machines begins with data collection. MachineMetrics connects directly to the machine control for deep machine connectivity. Note: We also connect to legacy assets to ensure that all types of .

The integration of IoT with CNC machines is transforming manufacturing workflows. Data-driven insights enable more agile production methods, rapid prototyping, and dynamic response to market demands. The traditional linear production line is giving way to a more flexible, modular, and scalable approach.Automation in CNC (Computer Numerical Control) machining refers to the integration of advanced technologies that enable machines to operate with minimal human intervention. This technology-driven approach is designed to enhance efficiency, productivity, and precision in .

Integrating CNC (Computer Numerical Control) machines into an existing production line can greatly improve efficiency, precision, and flexibility. However, the process requires careful planning to ensure the integration is seamless and does not disrupt the workflow. The following Section of the presented work describes the development of an information integration procedure for CNC machines, using OPC UA as the foundational technology, thus providing machines with a standardized interface for further uses in Smart Factory environments.

CNC machines have been a staple of manufacturers but they are now being paired with automation systems and simulation software to increase production. Machine integration is the process of collecting, processing, and standardizing data from manufacturing equipment and connecting it to shop floor systems, such as an MES or ERP. Integrating equipment combines the benefits of real-time data collection and analytical capability with critical enterprise software. CNC allows operators to program specific machining operations into machine tools. Using computers to direct the tools provides higher levels of precision and accuracy than manual controls, but even more importantly, it provides an element of automation. The integration of robotic systems with used CNC machines has become a key strategy for improving automation and productivity in the ever changing landscape of manufacturing. In this article, we explore the intricacies and advantages of robotics and used CNC machinery working together, offering a complete guide for manufacturers who want to improve .

machine integration tools

2020 Insight integrates CNC technology by generating and distributing CNC programs for any machine—including integrated machine lines, point-to-points, routers, edgebanders and panel saws—and eliminates the need for manual programming. The integration of IIoT technology with CNC machines begins with data collection. MachineMetrics connects directly to the machine control for deep machine connectivity. Note: We also connect to legacy assets to ensure that all types of .

The integration of IoT with CNC machines is transforming manufacturing workflows. Data-driven insights enable more agile production methods, rapid prototyping, and dynamic response to market demands. The traditional linear production line is giving way to a more flexible, modular, and scalable approach.Automation in CNC (Computer Numerical Control) machining refers to the integration of advanced technologies that enable machines to operate with minimal human intervention. This technology-driven approach is designed to enhance efficiency, productivity, and precision in .

cnc milling machine service

cnc milling machine tutorial

Sheet metal dome fabrication is an essential process in the manufacturing industry that involves transforming flat sheets of metal into precise, three-dimensional shapes. Original Equipment .

cnc machine integration|machine integration process