cnc machine preventive maintenance By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our . 1 was here. Umpqua Sheet Metal Inc provides sheet metal, industrial metal, direct digital controls, commercial HVAC, residential HVAC, & air purification.

0 · preventive maintenance for lathe machine

1 · preventative maintenance for cnc machines

2 · milling machine preventive maintenance checklist

3 · lathe machine preventive maintenance checklist

4 · cnc maintenance checklist pdf

5 · cnc machine maintenance training pdf

6 · cnc machine maintenance checklist pdf

7 · cnc machine maintenance checklist

$69.99

Contact your local distributorto have the following preventive maintenance performed by a certified Okuma Engineer: 1. Have the coolant tank cleaned of sludge, chips, and oil 2. Have the chuck and jaws taken off the machine and cleaned 3. Have the hydraulic tank drained and replace the hydraulic oil with fresh . See moreContact your local distributor and have the following inspected: 1. Have the headstock checked for taper 2. Have the spindle checked for radial and end play 3. Have the chuck cylinder . See more

Why is Preventive Maintenance Beneficial for you? 1. Reduces downtime. 2. Saves you money. 3. Reduces complete breakdowns. 4. Extends the lifespan of your machine and cutting tools. 5. Reduces repair costs from unexpected .

Preventive maintenance is crucial for CNC machines because it: Reduces Downtime: Regular maintenance prevents unexpected breakdowns .By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our .

An unplanned CNC machine breakdown typically costs about 5 times more than it does to create an annual maintenance plan, often called a “Preventive Maintenance Plan.” Maintenance done on a routine basis helps ensure that .Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean .

preventive maintenance for lathe machine

Preventive maintenance plays a critical role in ensuring the longevity and reliability of CNC machines. By proactively addressing potential issues before they become major problems, you .

Learn the importance of preventive maintenance for CNC machines. Discover best practices, checklists and how ATS can support your maintenance needs.HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify .

Okuma offers preventive maintenance tips to help keep your CNC machine running at peak performance while avoiding unplanned downtime.

Why is Preventive Maintenance Beneficial for you? 1. Reduces downtime. 2. Saves you money. 3. Reduces complete breakdowns. 4. Extends the lifespan of your machine and cutting tools. 5. Reduces repair costs from unexpected breakdowns. 6. Minimize crashes or accidents. 7. Keeps production steady.

preventative maintenance for cnc machines

Preventive maintenance is crucial for CNC machines because it: Reduces Downtime: Regular maintenance prevents unexpected breakdowns and minimizes production interruptions. Extends Machine Life: Proper care can significantly extend the lifespan of your CNC machine, protecting your investment.

By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our PDF guide for easy reference, and keep your CNC machine running smoothly.An unplanned CNC machine breakdown typically costs about 5 times more than it does to create an annual maintenance plan, often called a “Preventive Maintenance Plan.” Maintenance done on a routine basis helps ensure that CNC machines hold up; but what is that routine, and how often do tasks need to be completed?

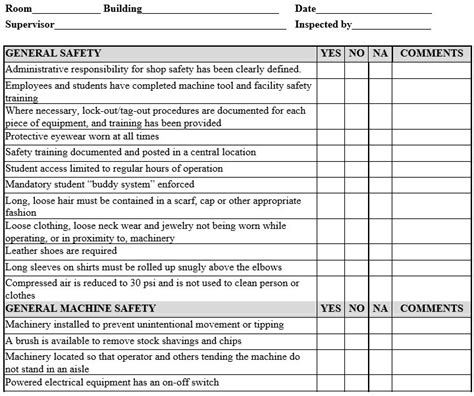

Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean slide rails, such as doors or covers, to maintain smooth movement. Electrical.Preventive maintenance plays a critical role in ensuring the longevity and reliability of CNC machines. By proactively addressing potential issues before they become major problems, you can avoid costly repairs, excessive downtime, and production delays.

Learn the importance of preventive maintenance for CNC machines. Discover best practices, checklists and how ATS can support your maintenance needs.HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify machine level

From before machine startup until after shutdown, preventative CNC maintenance takes place throughout the operating cycle. Detailed below are a few main areas on which to concentrate time and effort. Check all hydraulic fluid and liquid levels and ensure hydraulic pressure is adequate for operations.Okuma offers preventive maintenance tips to help keep your CNC machine running at peak performance while avoiding unplanned downtime.Why is Preventive Maintenance Beneficial for you? 1. Reduces downtime. 2. Saves you money. 3. Reduces complete breakdowns. 4. Extends the lifespan of your machine and cutting tools. 5. Reduces repair costs from unexpected breakdowns. 6. Minimize crashes or accidents. 7. Keeps production steady.Preventive maintenance is crucial for CNC machines because it: Reduces Downtime: Regular maintenance prevents unexpected breakdowns and minimizes production interruptions. Extends Machine Life: Proper care can significantly extend the lifespan of your CNC machine, protecting your investment.

milling machine preventive maintenance checklist

By following this preventive maintenance guide, you can minimize unexpected breakdowns, optimize machine performance, and extend the lifespan of your CNC machine. Download our PDF guide for easy reference, and keep your CNC machine running smoothly.An unplanned CNC machine breakdown typically costs about 5 times more than it does to create an annual maintenance plan, often called a “Preventive Maintenance Plan.” Maintenance done on a routine basis helps ensure that CNC machines hold up; but what is that routine, and how often do tasks need to be completed?

Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean slide rails, such as doors or covers, to maintain smooth movement. Electrical.Preventive maintenance plays a critical role in ensuring the longevity and reliability of CNC machines. By proactively addressing potential issues before they become major problems, you can avoid costly repairs, excessive downtime, and production delays.Learn the importance of preventive maintenance for CNC machines. Discover best practices, checklists and how ATS can support your maintenance needs.HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify machine level

06 ford expedition centersl junction box locsation

1 16 metal sheet

Oldcastle Infrastructure’s underground pull boxes and handholes are the industry’s leading product choice to protect and provide access to electrical cables and transformers and are a preferred alternative to running electrical power cables above the ground and across utility poles.

cnc machine preventive maintenance|cnc machine maintenance checklist