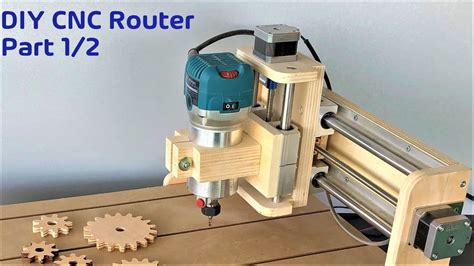

diy router cnc machine Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, . Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success.

0 · homemade cnc router machine

1 · do it yourself cnc router

2 · do it yourself cnc machine

3 · diy cnc routers for woodworking

4 · diy cnc machine for woodworking

5 · building your own cnc router

6 · building your own cnc machine

7 · build it yourself cnc router

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

homemade cnc router machine

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it .This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .

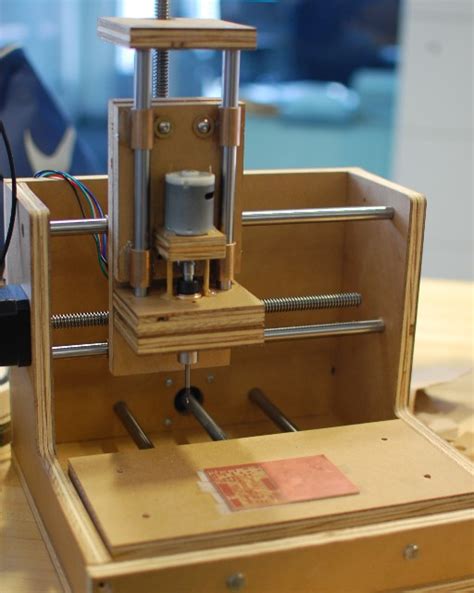

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be .While commercially available CNC router machines can be expensive, building your own DIY CNC router can be a cost-effective alternative for hobbyists and small-scale manufacturers. In .Learn how to build a DIY CNC router step by step, from preparing the workspace to final assembly and testing. Get valuable tips along the way. Before starting, I ensured my workspace was spacious enough to accommodate a 5-foot by 5 .

With a working area of 24"x48", you can build this for a lot less than the cost of a similar commercial CNC router. A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you .Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, . The best DIY CNC routers give you access to repeatable precision and reliability for your projects – without paying thousands of dollars for professional machines. My top choice for beginners is the Sainsmart Genmitsu 3018 PRO. It’s super easy to assemble, and at under 0, you can’t beat the value for money. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.While commercially available CNC router machines can be expensive, building your own DIY CNC router can be a cost-effective alternative for hobbyists and small-scale manufacturers. In this comprehensive guide, we will explore the step-by-step process of creating a .

Learn how to build a DIY CNC router step by step, from preparing the workspace to final assembly and testing. Get valuable tips along the way. Before starting, I ensured my workspace was spacious enough to accommodate a 5-foot by 5-foot CNC router.

With a working area of 24"x48", you can build this for a lot less than the cost of a similar commercial CNC router. A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router.

Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.

The best DIY CNC routers give you access to repeatable precision and reliability for your projects – without paying thousands of dollars for professional machines. My top choice for beginners is the Sainsmart Genmitsu 3018 PRO. It’s super easy to assemble, and at under 0, you can’t beat the value for money. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc.

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

do it yourself cnc router

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.While commercially available CNC router machines can be expensive, building your own DIY CNC router can be a cost-effective alternative for hobbyists and small-scale manufacturers. In this comprehensive guide, we will explore the step-by-step process of creating a .

Learn how to build a DIY CNC router step by step, from preparing the workspace to final assembly and testing. Get valuable tips along the way. Before starting, I ensured my workspace was spacious enough to accommodate a 5-foot by 5-foot CNC router. With a working area of 24"x48", you can build this for a lot less than the cost of a similar commercial CNC router. A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router.

ceiling boxes electrical

Komaspec has the capabilities to handle a wide range of sheet metal processes - everything from laser cutting, CNC bending, manual and robotic welding, stamping, threading, chamfering, and .

diy router cnc machine|diy cnc routers for woodworking