different sheet metal forming processes In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more.

It was dark so visibility was already a bit low, and to top it off, the yellow markings of the junction were heavily faded because the council don't maintain them properly. Obviously I understand how they work, but the above are examples of how you can get caught in one before you know it while driving honestly.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

If you’ve noticed a green box in your front yard, it could be an electrical junction box. These boxes are used to house connections and wiring for various electrical components, such as outdoor lighting or sprinkler systems.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different . The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a .Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface-area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

Based upon the manufactured components and the manufacturing process, various kinds of forming are developed. Different types of sheet metal forming processes and their applications and characteristics are discussed below: Roll forming; In this process the sheet metal is passed through a large numbers of set of rollers continuously. The each .

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more.

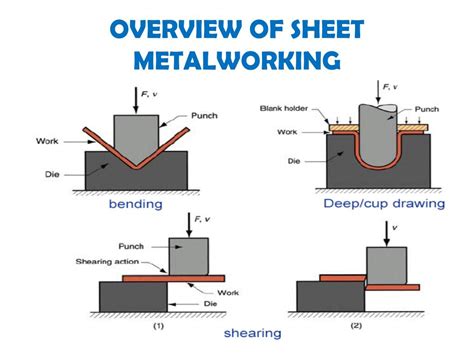

Sheet metal forming processes are typically performed at room temperature on machined tools called Presses using Dies. The parts are referred to as “Stampings”. Sheet metalworking processes. Sheet metalworking processes are classified into three categories: bending, sheet metal drawing, and shearing. Shearing – Cutting. Shearing; Blanking . Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications.

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve. Sheet metal forming is a fascinating world of engineering marvels. From the humble soda can to the sleek bodies of cars, these processes shape our daily lives. In this article, we’ll embark on a journey through the intricacies of sheet metal forming, guided by the insights of seasoned experts.In the manufacturing industry, four main conventional methods are used to fabricate a metallic product, i.e. casting, cutting, joining and metal forming. In casting, the molten material is poured into a mold, which contains a hollow cavity of the desired shape, and is then allowed to solidify. So the product can be shaped in one step.

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a .Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface-area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes. Based upon the manufactured components and the manufacturing process, various kinds of forming are developed. Different types of sheet metal forming processes and their applications and characteristics are discussed below: Roll forming; In this process the sheet metal is passed through a large numbers of set of rollers continuously. The each .

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more. Sheet metal forming processes are typically performed at room temperature on machined tools called Presses using Dies. The parts are referred to as “Stampings”. Sheet metalworking processes. Sheet metalworking processes are classified into three categories: bending, sheet metal drawing, and shearing. Shearing – Cutting. Shearing; Blanking .

Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications.

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve.

Sheet metal forming is a fascinating world of engineering marvels. From the humble soda can to the sleek bodies of cars, these processes shape our daily lives. In this article, we’ll embark on a journey through the intricacies of sheet metal forming, guided by the insights of seasoned experts.

electric temperature control box for enail

sheet metal working process pdf

electric tiffin boxes

electric socket box cutter

electric stove top open box

electric train box car u.r.t.x 4750 dubuque

One of the defining features of 3-axis machining is its ability to handle straightforward projects that require basic geometry and machining on a single plane. While it is best suited for flat surfaces, it can also perform drilling, tapping, and contouring operations.

different sheet metal forming processes|sheet metal forming process pdf