how to model a folded sheet metal part solidworks Learn about the fold and unfold tools and how they can be used to help with cuts to our sheet metal part in SOLIDWORKS.Quick Tip presented by Tony Riggs of G. Whether you’re replacing siding, adding an electrical box or installing a light fixture .

0 · solidworks sheet metal tools

1 · solidworks sheet metal fold tool

2 · solidworks sheet metal design

3 · solidworks sheet metal components

4 · solidworks fold and unfold tools

5 · solidworks flattened state

6 · solidworks feature manager

7 · designing sheet metal parts

Shop Ply Gem 8.5-in x 7.5-in White/Woodgrain Vinyl Electrical .

solidworks sheet metal tools

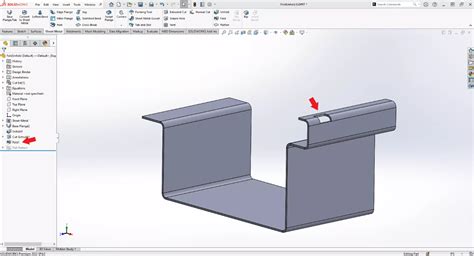

To create a sheet metal part from the flattened state: Open a new part. Create a sketch as shown. You do not have to dimension the part. Create a Base-Flange by clicking Base-Flange/Tab or Insert > Sheet Metal > Base Flange. The sheet metal features appear in the FeatureManager .

Learn about the fold and unfold tools and how they can be used to help with cuts to our sheet metal part in SOLIDWORKS.Quick Tip presented by Tony Riggs of G. In this quick tutorial, we explain how to use some of the sheet metal tools in SOLIDWORKS, specifically the Fold and Unfold tools. First, let’s set up our base flange, being sure to have a fully defined sketch to start. Check out hundreds of SolidWorks Tutorials at http://solidwize.com.This SolidWorks training video covers using the fold and unfold command in SolidWorks shee.

sheet metal tool box plans

solidworks sheet metal fold tool

To add a fold feature: In a sheet metal part, click Fold on the Sheet Metal toolbar, or click Insert > Sheet Metal > Fold. In the graphics area, select a face that does not move as a result of the feature for Fixed face . The fixed face can be a .

Attend a free SOLIDWORKS workshop right here 👉 https://josevaldir--learnsolidworks.thrivecart.com/action-takers-offer/61c45df2c28d8/ How To Model Complex Sheet Metal Parts in SOLIDWORKS. A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat .In this video tutorial, we will explore the different types of folds and flattens that can be achieved in SolidWorks. The steps are as follows: 1) Create a new part in the assembly file. 2) Open the . SolidWorks II Sheet Metal II Fold, Unfold and Flat Pattern with Detail Description. In this video, I am going to explain about Fold, Fold, Unfold and Flat Pattern in Solidworks. The.

Use the "Fold" or "Unfold" commands found in the Sheet Metal Toolbar, or access them through "Insert → Sheet Metal → Fold/Unfold". Unfolding reveals design modifications, while folding represents the ready-to-form part.

Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a .When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of . Check out hundreds of SolidWorks Tutorials at http://solidwize.com.This SolidWorks training video covers using the fold and unfold command in SolidWorks shee.

In a sheet metal part, click Fold on the Sheet Metal toolbar, or click Insert > Sheet Metal > Fold. In the graphics area, select a face that does not move as a result of the feature for Fixed face. The fixed face can be a planar face or linear edge.You may want to design a sheet metal part from the flattened state. In this case, you create a sheet metal part, then insert bend lines on which to fold the part. . or other features to the folded model. Instead, . SOLIDWORKS includes sheet metal-specific features so you can create a part as sheet metal without having to convert it to sheet . in this tutorial video you will learn about how to use of sheet metal fold & unfold command in Solidworks and create holes in pipes. I hope you like it.Pleas.

sheet metal tig welding

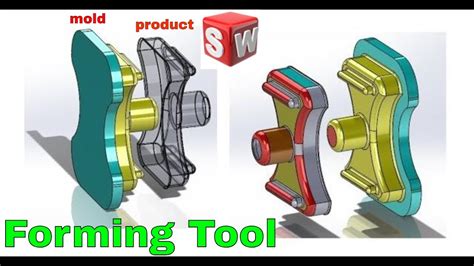

Started with forming tools on a sheet metal part, but I couldnt create a forming tool without a flat face. I am now sitting with something close to what I want, but the geometry isnt quite right. I am looking to make small dimples in a part, so I want the end result to be a dome with no flat faces.

Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Completing the Sheet Metal Drawing. Next, add a view of the unfolded model.

SolidWorks II Sheet Metal II Fold, Unfold and Flat Pattern with Detail Description.In this video, I am going to explain about Fold, Fold, Unfold and Flat Pa.

The main tool at your disposal to fold a sheet metal body up from a flat piece is "Sketch Bend" (GoEngineer - SOLIDWORKS: Sheet Metal Sketched Bend). This cannot directly make a conic bend though. . makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.Stp files don't include the necessary information to convey that it is a sheet metal part. When you make sheet metal parts in OnShape or Solidworks, more information than just the 3D model is being created and processed. It's how these programs know that a bend is impossible or how to unfold. You need a more descriptive file or remake the model. First, right-click on the main face of your SOLIDWORKS Sheet Metal part and select Export to DXF / DWG. Next, save the DXF file with your desired file name and location. In the options, select Sheet Metal. . If your model had countersink geometry or engravings, you might decide to remove them from the DXF file before it goes to laser cutting. .If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. . I normally would generate both a flat pattern as well as a folded views of the model, but I feel that it is way overkill to dimension every tiny little indent and notch and .

SolidWorks: Sheet Metal. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. When creating a sheet metal____, create the profile in that shape from the start. cone or cylinder . _____is intended to be the last feature in the folded sheet metal part. Flat Pattern feature. Bend Tables. Specifies the bend allowance or bend deduction values for a .3) Select one of these options: Unfold, Fold or Flatten. 4) Select your desired option from the drop-down list that appears next to each option name (Unfold, Fold or Flatten). 5) Click "Apply". Fold & Unfold Sheet Metal Surfaces in SolidWorks When it comes to sheet metal, folding and unfolding surfaces can be a challenge.

Ever wonder why your sheet metal drawing view doesn't flatten after you've made a change? We'll be going over 2 ways to make sure your change sticks while pr. SolidWorks Sheet Metal Tutorial for Beginner - 2 | Closed Corner, Welded Corner, Break Corner, Corner Trim, Forming Tool. This tutorial shows how to create f.You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export Dxf files to other applications, such as punch press or laser-cutter programming software. . For example, in sheet metal parts with up and down bend directions, you can map the .

Quick question for everyone, theres probably a simple answer to this but I just can't find it. Anyway.I'm importing a flat pattern of a part i'm making, extruding it and converting it to sheet metal. I want to create folds in the model but can't figure out how to do this, tried using the 'Fold' command but I could not select the area to leave .Hi there, I was wondering if it was possible to put down a decal on a sheet metal part that has been folded out, and then unsupress the flat pattern to fold normally again, with the decal still intact. I am working with sheet metal for a cardboard project, and would love to make some renders with the decals on there. Solidworks tutorial Sheet metal fold and unfold command | sheet metal flatten solidworks | CADable | CADable tutorialsWelcome back to CADable. This is Engr. .Sheet Metal - Flat and Folded States. When designing Sheet Metal parts in SOLIDWORKS, configurations are used to represent the folded and flattened states. The flattened state configuration represents the manufacturing definition of the finished part. . The default behavior when adding a weldment feature to a part model includes the creation .

Model Display: Mold Design: Motion Studies: Parts and Features: Routing: . When you mirror features and bodies in a sheet metal part, many of the bends are mirrored as well. The only bends that are not mirrored are those that are normal to and coincident to the mirror plane; those bends are extended. . Search 'Mirroring Sheet Metal Parts .When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .

Dear Viewers, In this video you will learn that how to make a Cut Across Bend for creating the slot in Sheet Metal with help of Fold, Unfold and Extruded-Cu.

In a sheet metal part, click Fold on the Sheet Metal toolbar, or click Insert > Sheet Metal > Fold. In the graphics area, select a face that does not move as a result of the feature for Fixed face. The fixed face can be a planar face or linear edge.

solidworks sheet metal design

$185.00

how to model a folded sheet metal part solidworks|solidworks sheet metal components