cnc machines programming pdf G-Code is the most common language used to control CNC machines. CNC stands . From there, you can determine which welder is best for you. The most common processes are MIG, TIG and stick. Each has benefits and limitations for certain applications. There’s no one-size-fits-all approach. MIG/Gas Metal Arc Welding (GMAW) — MIG welders use a wire welding electrode on a spool fed automatically at a constant pre-selected speed.

0 · cnc turning machine programming pdf

1 · cnc programming pdf free download

2 · cnc programming for dummies pdf

3 · cnc programming for beginners pdf

4 · cnc programming books free download

5 · cnc machine pdf download

6 · cnc machine codes list pdf

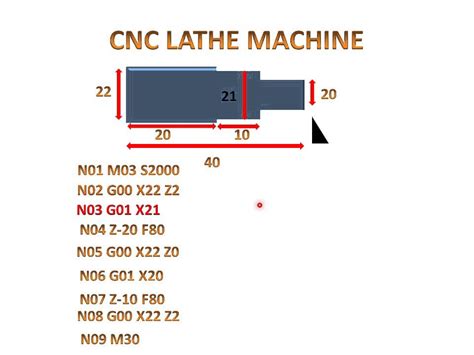

7 · cnc lathe programming example pdf

To cut a hole for a round electrical box, use a 4 1/8-inch hole saw for standard installations. For an Arlington fiber round box, a 3 5/8-inch hole saw is suitable. Ensure .

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.G-Code is the most common language used to control CNC machines. CNC stands .Two types of programming modes, the incremental system and the absolute system, are used for CNC. Both systems have applications in CNC programming, and no system is either right or .A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC .Chapter 1. The basic knowledge for programming. This chapter discusses the terms and commands you should know before learning CNC programming. 1.1 Configuration of the .

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .TABLE OF CONTENTS. 1 - NUMERICAL CONTROL 1. DEFINITION OF NUMERICAL CONTROL . . . 1. NC and CNC Technology . . . . . . . . . . . . . 1. CONVENTIONAL AND CNC .Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. . ppt on cnc - Download as a PDF or view online for free. . FEATURES OF CNC MACHINES 8. CNC PROGRAMMING BASICS 9. COMMON FORMAT OF A BLOCK 10. PROGRAMMING KEY LETTERS 11. .

by running a CNC program. A CNC program is loaded into the Control Computer, which then is executed causing the machine to perform the movements programmed in the file. The G - Code Programming Language is the name of the language that the CNC machine can understand and convert into actual motion of the machine. The Control CNC machine - Download as a PDF or view online for free. . (APT) programming language 1960 - Direct Numerical Control (DNC). This eliminates paper tape and allows programmers to send files directly to .

for CNC controls. By the late 1970’s, no true NC machines were being made, only CNC. ØDuring the 1980’s, many machine manufactures took advantage of PC technology to increase the reliability and decrease the cost of CNC controls. ØToday, all machines are CNC although the term NC is still used, but not in its original definition.G-Code is the language used to control CNC machines. It's one type of CNC programming that CNC programmers use, the other type being CAM programming. Your machine's CNC controller probably executes g-code, although there are other possibilities--Heidenhain, Mazak, and others have proprietary formats. Some machinesOverview. Written in a simple, easy-to-understand language by Ken Evans, a skilled programmer with many years of experience teaching CNC machining to industry and in the classroom, this new edition of Programming of CNC Machines offers a new chapter on feature-based Machining using Siemens, plus a new chapter featuring Fanuc NC guide I programming.each time the program is run. To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, .

quality control functions during the actual machining. • All CNC machining begins with a part program, which is a sequential instructions or coded commands that direct the specific machine functions. • The part program may be manually generated or, more commonly, generated by computer aided part programming systems. OverviewPDF; PHILICAM; Picocnc; Planet CNC; PLC; PRODIGY; Pronum CNC; ProtoTRAK; . CNC Manual / Denford / Denford G and M Programming Manual for CNC Milling Machines. Denford G and M Programming Manual for CNC Milling Machines . DENFORD VR CNC Milling 5.0. 1 pages. DENFORD Vertical Router CNC Machine User Manual. 41 pages. DENFORD Product .Section 2: CNC Milling Machine Programming Techniques . Now that we have grasped the fundamentals, it's time to dive into the practical aspects of CNC milling machine programming. . Section 5: PDF Resources for CNC Milling Machine Programming . In this section, we provide a curated list of downloadable PDF resources for further learning and .

Format of machining program. In the formatting of machining program, one or more “word” (command) constitute one line. The sign of new line at the end of a line is shown as “;” on CNC display screen. One line of machining program is called a “block”. Write “%” at the end of the machining program. The machining program will be .CNC Machining Handbook About the Author Alan Overby received a B.S. in Electrical Engineering from Arizona State University. He has always had a hobbyist interest in CNC technology, and has owned, programmed, and operated several CNC routers and engraving machines on a professional level within the signage industry. What is CNC programming: CNC programming is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece.; How to learn CNC programming: The best way to learn CNC programming is to find a CNC shop that is hiring and start as a machine tool operator.You can also watch online tutorials and use .

Hello! To kick-start the incorporation of CNC machines courses and programming, you will need necessary and adequately strong machines such as CNC milling machines, CNC lathes, and CNC routers. These machines will .PDF | On Jan 1, 2023, Mohd Asif Hasan and others published Agility enhancement in CNC machines through parametric programming | Find, read and cite all the research you need on ResearchGateWritten in a simple, easy-to-understand language by a skilled programmer with many years of experience teaching CNC machining to industry and in the classroom, this new edition offers a new chapter on feature-based Machining using Siemens, plus a new chapter featuring Fanuc NC guide I programming.If you have never run a cnc machine before, these programs should be a good example of what your machine will need to do to get to a finished project successfully. I programmed them so they are usable on a 3018 cnc engraver, these machines are probably the least capable you can buy. So if the programs can run on them, they can run on any machine.

china stamped sheet metal parts suppliers

Search the Wayback Machine. An illustration of a magnifying glass. Mobile Apps. Wayback Machine (iOS) Wayback Machine (Android) . CNC programming : principles and applications by Mattson, Mike. Publication date 2002 . Pdf_module_version 0.0.22 Ppi 360 Rcs_key 24143 Republisher_date .machining but not those that are actual tool movements. That is, they are auxiliary functions, such as spindle on and off, tool changes, coolant on and off, program stops, and similar related functions. The following codes are described in more detail in the following sections. M00 Program stop M01 Optional program stop M02 Program end M03 .Read & Download CNC Machine Manuals without Limits on any device. Your best companion in cnc machine shop. CNC programming operating manuals and many more

CNC part programming - Download as a PDF or view online for free. Submit Search. CNC part programming • Download as PPTX, PDF • 6 likes • 9,443 views. jntuhcej Follow. CNC machines use computer programs and numeric control to operate machine tools like milling machines and lathes. Key features include automated tool changes and multi-axis .cnc plasma cutting machine programming pdf. On demand manufacturing online CNC Machining Services. If you need custom machined parts with complex geometries, or get end-use products in the shortest possible time, sigma technik limited is good enough to break through all of that and achieve your idea immediately.

ix, 466 pages : 24 cm Gain a thorough understanding of computer-based numerical control systems, components, and technologies. Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.Chapter 2: Exploring PDF Resources for CNC Turn-Mill Programming. Next, we will delve into the world of PDF resources for CNC turn-mill programming. PDFs can be a valuable asset in organizing and storing important information such as part drawings, machine specifications, and programming codes. Clarification: The punch tape reader in a CNC machine is an input device. Magnetic tape, as well as computer keyboard, can be used in CNC as an input device. The feedback system is to record the data from the sensor and compare it with input data. CNC machine uses the program to control motion and speed. 6.CNC Machining Handbook: Building, Programming, and Implementation . Authors: Alan Overby. Published: October 2010. eISBN: 9780071623025 . Book Description Table of Contents Contents; Preface; Part I: The Physical Architecture; 1 CNC Machines; Common CNC Applications; 2 Guide Systems; Round Rail; Profile Rail; V-Style Roller; Hybrid Roller .

cnc turning machine programming pdf

cnc programming pdf free download

cnc programming for dummies pdf

To become a metal fabricator, you need to have a high school diploma or equivalent, and preferably some vocational training or apprenticeship in metalworking. You also need to.

cnc machines programming pdf|cnc lathe programming example pdf