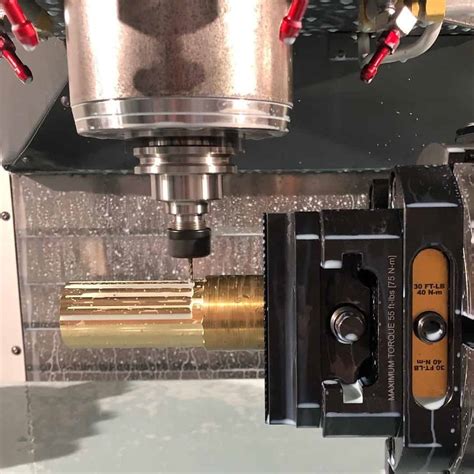

cnc turning copper part Turning for Copper Parts. This manufacturing process requires affixing the copper materials in a position. More so, the cutting tools fed to the workpiece remain stationary. Hence, the turning copper material at the proper set speed reduces in size to the desired dimension. An electrical enclosure is used in many different applications where housing and protecting electrical equipment is required. It provides a safe, weather-resistant space for electrical components, while also protecting against unauthorized access.

0 · turning for copper parts

1 · copper machining tips

2 · copper machining process

3 · copper cnc machining process

4 · copper cnc machining materials

5 · copper cnc machinery

6 · copper cnc cutting speed

7 · best copper for cnc machine

Selecting the right electrical box for your project can be confusing because of the many options available. Whether you’re starting new construction or adding to existing wiring, understanding the different types of electrical boxes helps for a safe installation.

What Is Copper CNC Machining? Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such .

The Art of Copper Turning. CNC turning is a cost-effective and precise technique for creating symmetrical copper components. In CNC turning of copper, it’s crucial to set the cutting tool edge angle between 70° and 95°, with a near 90° . What Is Copper CNC Machining? Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts.CNC Turning for Copper. CNC turning is another effective method for machining copper, where the tool remains stationary while the workpiece moves to achieve the desired shape. This adaptable approach is commonly used to create electronic and mechanical components. Turning for Copper Parts. This manufacturing process requires affixing the copper materials in a position. More so, the cutting tools fed to the workpiece remain stationary. Hence, the turning copper material at the proper set speed reduces in size to the desired dimension.

By understanding the basics of CNC turning, familiarizing yourself with the properties of copper, and following the step-by-step instructions provided in this guide, you can confidently tackle the challenges of machining copper on a CNC lathe. CNC turning of copper materials requires precision, expertise, and best practices to achieve high-quality results. With the increasing demand for copper parts in various industries, it is essential to share experiences and techniques for achieving the best outcomes.

turning for copper parts

CNC turning is a crucial machining process that revolutionizes the production of copper parts. With its precision and versatility, CNC turning allows for the creation of intricate and customized copper components.eMachineShop has machined copper parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA.CNC Turning. Another technique for machining copper is CNC turning, where the tool remains stationary, while the workpiece moves to produce the desired shape. CNC turning is an adaptable machining system used to make many electronic and mechanical components.

Choosing the right CNC turning copper parts manufacturer is crucial to ensure the quality and reliability of the end product. In this comprehensive guide, we will discuss key factors to consider when selecting a manufacturer for CNC turning copper parts. The Art of Copper Turning. CNC turning is a cost-effective and precise technique for creating symmetrical copper components. In CNC turning of copper, it’s crucial to set the cutting tool edge angle between 70° and 95°, with a near 90° . What Is Copper CNC Machining? Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts.CNC Turning for Copper. CNC turning is another effective method for machining copper, where the tool remains stationary while the workpiece moves to achieve the desired shape. This adaptable approach is commonly used to create electronic and mechanical components.

Turning for Copper Parts. This manufacturing process requires affixing the copper materials in a position. More so, the cutting tools fed to the workpiece remain stationary. Hence, the turning copper material at the proper set speed reduces in size to the desired dimension.

By understanding the basics of CNC turning, familiarizing yourself with the properties of copper, and following the step-by-step instructions provided in this guide, you can confidently tackle the challenges of machining copper on a CNC lathe. CNC turning of copper materials requires precision, expertise, and best practices to achieve high-quality results. With the increasing demand for copper parts in various industries, it is essential to share experiences and techniques for achieving the best outcomes.CNC turning is a crucial machining process that revolutionizes the production of copper parts. With its precision and versatility, CNC turning allows for the creation of intricate and customized copper components.eMachineShop has machined copper parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA.

CNC Turning. Another technique for machining copper is CNC turning, where the tool remains stationary, while the workpiece moves to produce the desired shape. CNC turning is an adaptable machining system used to make many electronic and mechanical components.

copper machining tips

The Septic Distribution Box. The distribution box (or d-box) is usually made of concrete, fiberglass, or plastic. It can differ in size and shape, depending on the septic needs of the household. It is a box with an inlet pipe to send the water from the tank and many outlet holes to disperse the treated water through multiple field lines.

cnc turning copper part|turning for copper parts