2-sided cnc machining An introduction to 2 Sided Machining of symmetrical parts with a Probotix Asteroid CNC Router. Reproducible fixture and material reference points for both X. The perfect size for automotive sheet metal is between 18 to 20 gauge. 20 gauge is the most used gauge sheet metal for automotive functions. The abundant metal will be 0.0478 to 0.0359 inches and still need to be .

0 · vectric two sided machining

1 · vectric 2 sided machining

2 · vectric 2 sided carving

3 · vcarve two sided machining

4 · vcarve 2 sided machining

5 · how to use locating pins

6 · fusion 360 2 sided machining

7 · aspire 2 sided machining

Yes, you can use acrylic paint on dark-colored fabric, but you may need to apply a base coat of white or a lighter color to make the acrylic paint stand out. It’s also important to use fabric medium with your acrylic paint to ensure it adheres properly .

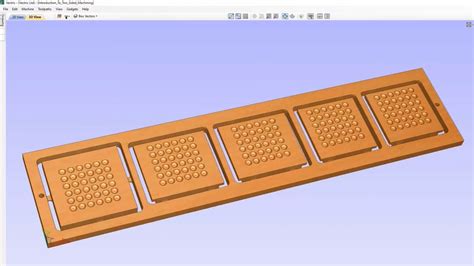

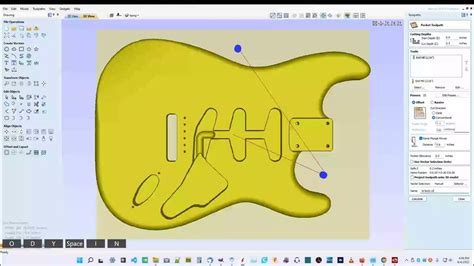

We start with a general discussion of the concept and look at options for how you can accurately align a two sided part. We then look at an actual file and work through the basic two-sided. In this article, I'll demonstrate how to approach two-sided machining on a CNC router by creating a lidded box, a project that uses two separate two-sided setups—one for the box and one for the lid.

An introduction to 2 Sided Machining of symmetrical parts with a Probotix Asteroid CNC Router. Reproducible fixture and material reference points for both X.

One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece. In this blog post, we will explore the various aspects of . In this video Ryan shows you how to machine both sides of your project on the WorkBee CNC Machine - if you've got any questions then feel free to ask in the .

Model of CNC Machine: Shark-Sherline-Diode Laser-Ender3-K40 Location: Frogmore, LouisianaTwo-Sided Machining. Aspire has the ability to create a project where your design requires you to cut both sides of your material. Typically you will cut the top surface of your material, then .

vectric two sided machining

We start with a general discussion of the concept and look at options for how you can accurately align a two sided part. We then look at an actual file and work through the basic two-sided.

In this article, I'll demonstrate how to approach two-sided machining on a CNC router by creating a lidded box, a project that uses two separate two-sided setups—one for the box and one for the lid. An introduction to 2 Sided Machining of symmetrical parts with a Probotix Asteroid CNC Router. Reproducible fixture and material reference points for both X.

One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece. In this blog post, we will explore the various aspects of CNC two-sided machining, including its benefits, setup procedures, tool .

In this video Ryan shows you how to machine both sides of your project on the WorkBee CNC Machine - if you've got any questions then feel free to ask in the .

vectric 2 sided machining

Model of CNC Machine: Shark-Sherline-Diode Laser-Ender3-K40 Location: Frogmore, Louisiana

Two-Sided Machining. Aspire has the ability to create a project where your design requires you to cut both sides of your material. Typically you will cut the top surface of your material, then manually turn the material block over on your machine, whilst maintaining a common registration position, and cut the bottom surface using a second set . alex pavel wrote: I need to machine some pieces on both sides and they need to align perfectly. What would be the best strategy for this? Did anyone try a 3D probe? Is it more precise than using dowels? Absolutely not. One thing you should keep in mind is that imported stl/obj files are converted into a pixel based representation.

Can you do two sided carving with Carveco Maker? I see nothing for index holes or anything remotely familiar. I have googled, went to Carveco, and YouTube and I must be using wrong terminology or something. Can some of you very smart people help?Two-Sided Machining - Part 30 - Aspire and VCarve For Absolute BeginnersMore down here ↓↓↓ Click SHOW MORE!This is the 30th in a series of videos geared tow.

We start with a general discussion of the concept and look at options for how you can accurately align a two sided part. We then look at an actual file and work through the basic two-sided. In this article, I'll demonstrate how to approach two-sided machining on a CNC router by creating a lidded box, a project that uses two separate two-sided setups—one for the box and one for the lid.

An introduction to 2 Sided Machining of symmetrical parts with a Probotix Asteroid CNC Router. Reproducible fixture and material reference points for both X.One particularly useful technique is two-sided machining, which allows for the simultaneous milling of both sides of a workpiece. In this blog post, we will explore the various aspects of CNC two-sided machining, including its benefits, setup procedures, tool .In this video Ryan shows you how to machine both sides of your project on the WorkBee CNC Machine - if you've got any questions then feel free to ask in the . Model of CNC Machine: Shark-Sherline-Diode Laser-Ender3-K40 Location: Frogmore, Louisiana

vectric 2 sided carving

Two-Sided Machining. Aspire has the ability to create a project where your design requires you to cut both sides of your material. Typically you will cut the top surface of your material, then manually turn the material block over on your machine, whilst maintaining a common registration position, and cut the bottom surface using a second set . alex pavel wrote: I need to machine some pieces on both sides and they need to align perfectly. What would be the best strategy for this? Did anyone try a 3D probe? Is it more precise than using dowels? Absolutely not. One thing you should keep in mind is that imported stl/obj files are converted into a pixel based representation.

Can you do two sided carving with Carveco Maker? I see nothing for index holes or anything remotely familiar. I have googled, went to Carveco, and YouTube and I must be using wrong terminology or something. Can some of you very smart people help?

3-wat electrical junction box

3mm to gauge sheet metal

I have to imagine that there is a junction box in which I use a wire-cap to connect 3 neutral wires (the incoming, the one to the load, and the one that continues to the next load). How is that different from the example given in post #3?

2-sided cnc machining|vectric 2 sided machining