parting operation in sheet metal In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. . $7.99

0 · slotting in sheet metal

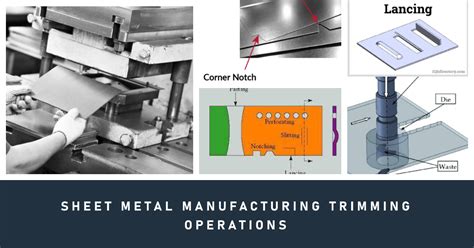

1 · sheet metal trimming operations

2 · sheet metal parting process

3 · sheet metal parting operations

4 · sheet metal cutting operation

5 · sheet metal cut out process

6 · notching operation sheet metal

7 · lathe parting process

Fusion Metalworks excels in trash enclosure gates because we understand the constant barrage and abuse a trash enclosure gate receives and pay special attention to the hinges, gate clasp and bottom pins.

Parting, also known as parting off, is a lathe machining operation used to cut off a workpiece from a larger stock material. The primary purpose of parting is to separate a finished or semi-finished component from the rest of the material, . In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. .Blanking is a cutting process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force.In this process, the piece removed, called the blank, is not scrap but rather the desired .A parting operation cuts a slug between adjacent parts in the strip. See Figure 20.8. . elastic recovery of the sheet metal after bending; it is usually measured as the difference between the final included angle of the bent part and the angle of the tooling used to make the bend, .

a shearing operation in which blanks are separated from a sheet-metal strip by cutting the opposite sides of the part in sequence. parting. involves cutting a sheet metal strip by a punch with two cutting edges that match the opposite sides of the blank. One of the greatest challenges within a parting or slitting operation is getting a clean edge that requires no secondary operation to remove nibble marks or burrs. 6/19/2019 Often, operators think burring is a tooling problem, but that’s not always the case.general sheet metal shearing operation that consists of perforating, parting, notching, and/or lancing. Perforating. die cutting operation in which a number of small holes are punched in sheet metal. Parting. die cutting operation in which sheet metal is sheared into two or more pieces.Quiz yourself with questions and answers for sheet metal quiz, so you can be ready for test day. . parting. sectioning. 11 of 31. Term. Removing pieces of various shapes from the edges of a sheet . punching. 13 of 31. Term. A shearing operation typically carried out with a pair of circular blades Can follow straight line, circular, or .

Keywords: shearing operation, blanking and punching, slotting, parting. 1. Sharing operation of high strength steel sheet 1] Author is J.Manufmater /in 2020. in steel sheet achieve a high strength. 2. Sheet metal cutting and blanking. 2] Author is Ariacutty jaendran/in 2018. Blanking Operation is perform the highly accuracy. 3.Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for subsequent operations. This article presents an analysis of parts to be trimmed and describes the selection criteria for the different types of trimming dies such as conventional trimming dies and cam trimming dies .

slotting in sheet metal

Sheet metal piercing using high quality piercing punches and oil. Learn how to improve tool life, increase productivity and solutions to common problems. . This is similar to cutoff operation. But the difference between parting off and cutoff is that, parting-off produces wastage of material. Depending on the shape of the contour, the wastage . SMF Operations Shaving is removing of thin strip of metal along edges to obtain smooth and straight edges of accurate dimensions. Perforating is punching a number of small holes in a sheet. Parting or shearing sheet into two or more pieces usually when the adjacent blanks do not have matching contour. Slitting is a shearing operation carried .Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. Blanking. The term blanking can be somewhat confusing, because it has more than one definition. The blank is defined as the flat piece of sheet metal that eventually turns into the finished piece part.. Blanking is a method in which the sheet metal is cut and the slug is saved for further pressworking. The size and the shape of the blank are proportional to the size and .

Get Sheet Metal Operation Multiple Choice Questions (MCQ Quiz) with answers and detailed solutions. Download these Free Sheet Metal Operation MCQ Quiz Pdf and prepare for your upcoming exams Like Banking, SSC, Railway, UPSC, State PSC. . Parting - Separating a part from the remaining sheet, by punching away the material between parts .In sheet metal, this question always creates some confusion. What is the difference between punching blanking and piercing? Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar .

In sheet metal cutting operations the metal parts are separated by applying a shear force which develop stresses greater than the shearing strength of the sheet metal to be cut. Cutting edges to cut the metal are provided by the punch (inner cutting edge) and . Parting operation: Cuts a slug between adjacent parts in the strip; Notching and Seminotching Operations. Notching operation: Cuts out a portion of the sheet metal from the interior of the sheet or strip; Seminotching operation: Removes a portion of the sheet metal from the interior of the sheet or strip; Sheet Metal Bending V-bending. Uses a . Finishing operations are usually necessary when nibbling metal sheets to maintain accuracy in the shape geometry and surface quality. Lancing. . Parting. Parting separates the sheet metal into two or more pieces by removing the connecting material between them. The separation is performed by cutting blades and the connecting piece between the .

Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .Sheet bending Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending causes no change in the thickness of the sheet metal. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve. It is a manufacturing process used to cut off a plate needed for a particular application, usually done with a .

In blanking the part separated from the sheet metal is the product output and remaining sheet metal is the scrap metal. This process is employed in mass production of blanks that cannot be produced by shearing, cutting-off or parting operations. Operation # 5. Punching Operation: What is the metal steel slitting process operation? In metalworking, every new contract is a new bespoke challenge. With technological advances in slitting equipment, software and tool practices, the demand for coils with finer width and length parameters increased, ushering in an era of more accurate slitting. . With many years of experience .

sheet metal trimming operations

Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .

Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. The thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly

SHEET METAL PROCESS - Download as a PDF or view online for free . Typical shearing operations, bending and drawing operations – Stretch forming operations –– Formability of sheet metal – Test methods – Working principle and application of special forming processes . Punching Blanking Perforating Parting Notching Lancing 5.A sheet metal cutting operation that cuts out a portion of metal from the interior of a sheet or strip that will become part of the outline of the blank is called which one of the following: (a) cutoff, (b) notching, (c) parting, (d) seminotching, or (e) slotting?

sheet metal parting process

sheet metal parting operations

From a local estate, here is a very clean set of "Reflect-O-Light" safety reflectors. There are three sets in the metal box, each has a metal spring piece that holds them up somehow, not quite sure how they work but the springs are all there.

parting operation in sheet metal|sheet metal parting operations