aluminum shell core fabrication However, a flexible and simple fabrication method is needed. Here, a controllable femtosecond laser self-deposition technology was developed to fabricate Al@AlOx core/shell micropillars (MPs) with diverse size distribution on the aluminum surface in a single-step operation under ambient . $219.00

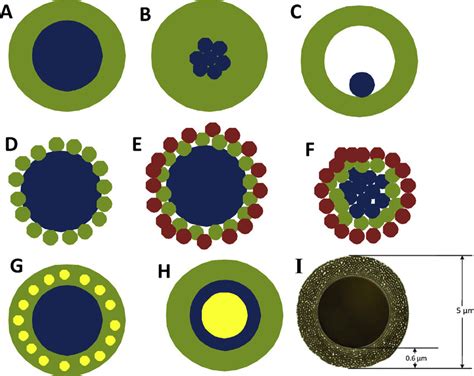

0 · types of core shell particle

1 · types of core shell microparticles

2 · solid core shell microparticles

3 · core shell nanoparticles

4 · applications of core shell microparticles

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .

However, a flexible and simple fabrication method is needed. Here, a controllable femtosecond laser self-deposition technology was developed to fabricate Al@AlOx core/shell micropillars (MPs) with diverse size distribution on the aluminum surface in a single-step operation under ambient . Here, a novel super encapsulating structured polyvinylidene fluoride@glycidyl azide polymer/nitrocellulose (PVDF@GAP/NC) core-shell . Fabricating core–shell microparticles with a desired size and distribution using conventional methods has long been a big challenge. These methods usually result in .

Core–shell nanostructures are the simplest of two-component system consisting of an inner layer which encapsulates a guest nanoparticle of different material. To overcome the . In this research, a prompt, eco-friendly and cost-effective method is presented to fabricate novel Au@Al 2 O 3 core-shell nanoparticles. It is a one-step method with continuous . Here, a novel super encapsulating structured polyvinylidene [email protected] azide polymer/ nitrocellulose ( [email protected]/NC) core-shell nanofibers with superior hydrophobic.

This review provides an overview of fabrication methods for core–shell particles followed by a brief discussion of their application and a detailed analysis of their manipulation including assembly, . Here, a controllable femtosecond laser self-deposition technology was developed to fabricate Al@AlOx core/shell micropillars (MPs) with diverse size distribution on the .

This review provides an overview of fabrication methods for core–shell particles followed by a brief discussion of their application and a detailed analysis of their manipulation including assembly, sorting, and .However, a flexible and simple fabrication method is needed. Here, a controllable femtosecond laser self-deposition technology was developed to fabricate Al@AlOx core/shell micropillars (MPs) with diverse size distribution on the aluminum surface in a . Here, a novel super encapsulating structured polyvinylidene fluoride@glycidyl azide polymer/nitrocellulose (PVDF@GAP/NC) core-shell nanofibers with superior hydrophobic characteristic and enhanced reaction performance was designed and manufactured by innovative coaxial electrospinning.

types of core shell particle

Fabricating core–shell microparticles with a desired size and distribution using conventional methods has long been a big challenge. These methods usually result in core–shell microparticles with high polydispersity, limited control over morphology and low reproducibility. Core–shell nanostructures are the simplest of two-component system consisting of an inner layer which encapsulates a guest nanoparticle of different material. To overcome the interfacial tension of core–shell, core can be coated with different ligands so as to improve interactions with shell. In this research, a prompt, eco-friendly and cost-effective method is presented to fabricate novel Au@Al 2 O 3 core-shell nanoparticles. It is a one-step method with continuous-wave fiber laser ablation on an Aluminum (Al) plate coated with gold (Au) nanolayer immersed in . Here, a novel super encapsulating structured polyvinylidene [email protected] azide polymer/ nitrocellulose ( [email protected]/NC) core-shell nanofibers with superior hydrophobic.

This review provides an overview of fabrication methods for core–shell particles followed by a brief discussion of their application and a detailed analysis of their manipulation including assembly, sorting, and triggered release. Here, a controllable femtosecond laser self-deposition technology was developed to fabricate Al@AlOx core/shell micropillars (MPs) with diverse size distribution on the aluminum surface in a single-step operation under ambient conditions.

This review provides an overview of fabrication methods for core–shell particles followed by a brief discussion of their application and a detailed analysis of their manipulation including assembly, sorting, and triggered release.

In this chapter, the main focus was on some major synthesis techniques for the fabrication of core-shell nanostructures and various techniques employed for functionalizing the core, shell, or both in order to achieve improved and .However, a flexible and simple fabrication method is needed. Here, a controllable femtosecond laser self-deposition technology was developed to fabricate Al@AlOx core/shell micropillars (MPs) with diverse size distribution on the aluminum surface in a . Here, a novel super encapsulating structured polyvinylidene fluoride@glycidyl azide polymer/nitrocellulose (PVDF@GAP/NC) core-shell nanofibers with superior hydrophobic characteristic and enhanced reaction performance was designed and manufactured by innovative coaxial electrospinning.

Fabricating core–shell microparticles with a desired size and distribution using conventional methods has long been a big challenge. These methods usually result in core–shell microparticles with high polydispersity, limited control over morphology and low reproducibility. Core–shell nanostructures are the simplest of two-component system consisting of an inner layer which encapsulates a guest nanoparticle of different material. To overcome the interfacial tension of core–shell, core can be coated with different ligands so as to improve interactions with shell.

In this research, a prompt, eco-friendly and cost-effective method is presented to fabricate novel Au@Al 2 O 3 core-shell nanoparticles. It is a one-step method with continuous-wave fiber laser ablation on an Aluminum (Al) plate coated with gold (Au) nanolayer immersed in . Here, a novel super encapsulating structured polyvinylidene [email protected] azide polymer/ nitrocellulose ( [email protected]/NC) core-shell nanofibers with superior hydrophobic.

types of core shell microparticles

This review provides an overview of fabrication methods for core–shell particles followed by a brief discussion of their application and a detailed analysis of their manipulation including assembly, sorting, and triggered release. Here, a controllable femtosecond laser self-deposition technology was developed to fabricate Al@AlOx core/shell micropillars (MPs) with diverse size distribution on the aluminum surface in a single-step operation under ambient conditions. This review provides an overview of fabrication methods for core–shell particles followed by a brief discussion of their application and a detailed analysis of their manipulation including assembly, sorting, and triggered release.

how to open metal boxes breath of the wild

how to paint metal house siding

My other thought is to just move the NEMA 10-30 outlet (or install a new NEMA 14-30) to the garage and use the existing outlet box as a junction box to tie-in the new cables. Then close the laundry room box up with a blank faceplate so it won't be usable anymore.

aluminum shell core fabrication|applications of core shell microparticles