2 ways to do sheet metal forming Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively . Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To complete the electrical circuit, tie together the same-colored wires and hold them in place with wire nuts.

0 · sheet metal processes pdf

1 · sheet metal operations with diagrams

2 · sheet metal forming process pdf

3 · forming stainless steel sheet metal

4 · forming sheet metal by hand

5 · forming aluminum sheet by hand

6 · custom tooling for metal forming

7 · custom sheet metal forming

For this "Building Skills" article, veteran electrician Brian Walo describes how to wire a switch box. After stressing the importance of neatness and logic in the wiring process, Walo goes step-by-step, starting with running and labeling .

Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost .

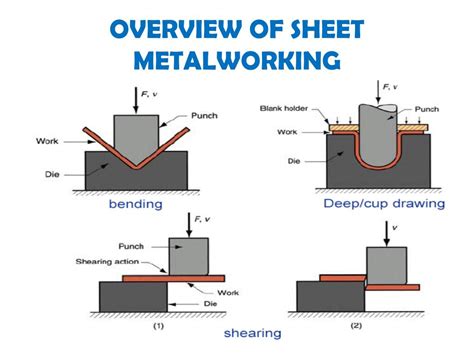

Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively . Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control. Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision. Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a .

Sheet metal forming leverages the malleability of metals, enabling flat metal sheets to undergo controlled plastic deformation and be manipulated into 3D shapes without tearing or compromising the material’s integrity.

Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end application process and covers forming techniques, equipment, challenges, and materials involved. Understanding Sheet .In this step-by-step guide, we’ll take you through the main processes of sheet metal fabrication, including designing the product, as well as cutting, welding, bending & forming, and finishing the metal.

2 axis cnc engraving machine

sheet metal processes pdf

Sheet metal forming involves transforming flat metal into various shapes and forms through multiple techniques. This manufacturing process uses mechanical force to bend, stretch, or compress the metal, allowing it to take on different forms suitable for various applications. Sheet metal forming involves reshaping the material by exerting force on it without cutting or removing pieces, thus pushing the sheet beyond its yield strength and causing plastic deformation rather than failure. There are six common sheet metal forming processes used by manufactures. They are; curling, bending, ironing, laser cutting, hydroforming and punching. Most manufactures will use multiple of those processes to produce their sheet metal.Sheet metal forming, also known as sheet metal deformation or sheet metal cutting, is an industrial technique that shapes metal sheets by deforming and chopping them. Shengen uses a range of techniques, such as bending, punching, and cutting, to create precision parts.

Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control. Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a . Sheet metal forming leverages the malleability of metals, enabling flat metal sheets to undergo controlled plastic deformation and be manipulated into 3D shapes without tearing or compromising the material’s integrity.

Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end application process and covers forming techniques, equipment, challenges, and materials involved. Understanding Sheet .In this step-by-step guide, we’ll take you through the main processes of sheet metal fabrication, including designing the product, as well as cutting, welding, bending & forming, and finishing the metal.

Sheet metal forming involves transforming flat metal into various shapes and forms through multiple techniques. This manufacturing process uses mechanical force to bend, stretch, or compress the metal, allowing it to take on different forms suitable for various applications. Sheet metal forming involves reshaping the material by exerting force on it without cutting or removing pieces, thus pushing the sheet beyond its yield strength and causing plastic deformation rather than failure. There are six common sheet metal forming processes used by manufactures. They are; curling, bending, ironing, laser cutting, hydroforming and punching. Most manufactures will use multiple of those processes to produce their sheet metal.

1-gang electrical box dimensions

sheet metal operations with diagrams

2 1 2 inch round junction box depot

sheet metal forming process pdf

Wiremold cable raceway products are designed to be aesthetically pleasing solutions for installing cables and power products in walls, floors, desks, or ceilings. Product lines include Wiremold raceway, junction boxes, and AV and power boxes for desktops, walls, and ceilings.

2 ways to do sheet metal forming|custom tooling for metal forming