father of cnc machine The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. The first NC machines were built in the 1940s and 1950s, based on . See more Smith & Wesson Box Handguns: The Revolver Forum. The Firing Line Forums > Hogan's Alley > Handguns: The Revolver Forum: Smith & Wesson BoxPull-Junction Boxes: Type - Pull - Junction Enclosure; Material - Steel; Material Specification - 16 Gauge; Finish - Gray; NEMA - 1; Cover Type - Screw-On; Dimension - Width - in - 6.00; .

0 · who invented cnc machines

1 · first numerical control machine

2 · first nc machine

It provides a number of short examples, in the form of calculation sheets, illustrating the design of structural hollow sections for beams and columns in buildings. All the examples were prepared by Miss M E Brettle and checked by Mr A S Malik of The Steel Construction Institute.speed railway simply-supported box girders upgrades the steel fabric from manual construction to automatic welding construction. The welding parameters of cross-

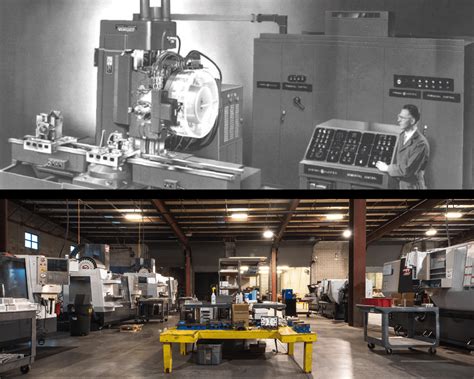

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. The first NC machines were built in the 1940s and 1950s, based on . See moreCamsThe automation of machine tool control began in the 19th century with cams that "played" a machine . See moreThe birth of NC is generally credited to John T. Parsons and Frank L. Stulen, working out of Parsons Corp. of Traverse City, Michigan. For this contribution, they were jointly awarded the National Medal of Technology in 1985 for "Revolutioniz[ing] Production Of Cars . See moreIn 1952, Arma Corporation which had done much defense work on rangefinders during the war, announced the first commercial numerically controlled lathe, developed by Dr. F. W. Cunningham. Arma's first automated lathe was made in 1948, and announced in 1950. See more

Many of the commands for the experimental parts were programmed "by hand" to produce the punch tapes that were used as input. During the development of Whirlwind, MIT's real-time computer, John Runyon coded a number of subroutines to . See moreAt that point Parsons conceived of a fully automated machine tool. With enough points on the outline, no manual working would be needed to . See moreThis was not an impossible problem to solve, but would require some sort of feedback system, like a selsyn, to directly measure how far the . See more

The Air Force Numeric Control and Milling Machine projects formally concluded in 1953, but development continued at the Giddings and Lewis Machine Tool Co. and other locations. In . See more John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.John T. Parsons (October 11, 1913 – April 18, 2007) pioneered numerical control (NC) for machine tools in the 1940s. These developments were done in collaboration with his Chief Engineer .

who invented cnc machines

The breakthrough came in the late 1950s when John T. Parsons and his team at the Massachusetts Institute of Technology (MIT) developed the concept of numerical control. They .John T. Parsons. Born January 7, 1913, Detroit, Mich.; the father of numerical control. Professional Experience: president and owner, Parsons Corp., Traverse City and Detroit, Mich., and Stockton, Calif, 1954-1968; president/owner, The . John T. Parsons is often credited as the father of modern CNC. His work in the 1940s to develop numerical control machining paved the way for the invention of the first CNC machine.

Who is the father of CNC machining? John T. Parsons is widely recognized as the father of CNC machining. His pioneering work in the 1940s, conceptualizing the use of numerical control for machine tools, laid the . John T. Parsons and the First Numerical Control Machines. As we dive deeper into the CNC history timeline, one name stands out – John T. Parsons.Many consider Parsons to be the father of modern CNC.The initial .

movie metal art house monogram

CNC Machine is PC controlled manufacturing machine responsible for producing a majority of the worlds goods. Rapid Results AI. Login / Signup. CNC Machines (1442) CNC Mill (798) . the precursor to the modern CNC machine. For his . 3. Introduction to CNC 3 Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is . 3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone. In .Explore the rich history of CNC machines and the influential father figures who shaped the manufacturing industry. Discover their contributions to precision engineering, automation, lean manufacturing, and sustainability, inspiring Racer Machinery International's cutting-edge solutions. Delve into the world of machining and the legacy of CNC machines in this .

The History of Computer Numerical Control (CNC) Jan 26, 2017. Since the industrial revolution, modern life has depended on advanced machinery to manufacture everything from textiles to steel.The advent of computer numerical control (CNC) machines revolutionized the manufacturing industry by allowing for a programmable design of virtually limitless types of shapes. A number of inventions were essential to laying the foundation for the development of CNC machines. . Douglas T. Ross, is known as the father of APT. He also later coined the term “computer .Machines range from hobbyist setups you can create for under ,000 to professional machines starting at 0K. There are machines optimized for different purposes; speed, precision, steel, aluminum, etc. There are machines with built-in tool change. Machines with liquid cooling. Machines with enclosures. The list goes on.

Evolution of CNC machine . Are you curious to know how CNC machines have developed over time? Let’s start from the very beginning and conclude our discussion with a look at the 21st century. 1940s: The Beginning . It is the period when all the chaos for the CNC machines started. John T. Persons brainstormed the idea of numerical control of .

The birth of numerical control. The universally recognised father of the NC is John T. Parsons.It was he, in fact, who, working in the family business, conceived and designed it together with the aerospace engineer Frank L. Stulen.The two, while studying the construction of helicopter rotor blades, were the first to use computing methods to solve machining problems. In 1989, CAD and CAM software-controlled machines became the industry standard for CNC machines. Today’s CNC Industry. The development of CNC machine tools is unique. From simple machines controlled by punch cards to software-driven machines are mysterious. Due to evolution, CNC machining has become faster, more precise, and more accurate . Image: WOTOL – T he Cincinnati Milacron Hydrotel. J.F. Reintjes led a team of researchers at MIT (Massachusetts Institute of Technology) in developing the prototype CNC milling machine. The first commercially available CNC machine, the Cincinnati Milacron Hydrotel, was developed by Richard Kregg in collaboration with MIT. This 28-inch vertical-spindle . A CNC machine is a system combining multiple tools (including drills, lathes, and milling tools), which are built into cells from which the machine can select and use them. It is designed to manufacture three-dimensional parts. . The Society of Manufacturing Engineers awarded him an honorary plaque in 1975, which named Parsons “The Father .

The history of Haas CNC machines started with their founder, . .1940’s: John T.Many consider Parsons to be the father of modern CNC.The first CNC machines were developed in the 1950s by John T.—into custom parts and designs. While working as a machinist at his father’s company in the 1940s, Parsons . Computer Numerical Control (CNC . It is important to mention Henry Maudslay, the British inventor known as the “Father of the Lathe”. Maudslay is to the lathe what James Watt is to the steam engine. In 1797, Maudslay created the world’s first thread-cutting .

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation . The head of the Computer Applications Group, Douglas T. Ross, is known as the father of APT. He also later coined the term “computer-aided design” (CAD). . At Bantam Tools, we make desktop CNC machines with .

Because of CNC machines, we have less expensive goods, stronger national defense and a higher standard of living than is possible in a non-industrialized world. In this article, we’ll explore the origins of the CNC machine, different types of CNC machines, CNC machine programs and common practices by CNC machine shops.

My father, a retired Aerospace Machinist taught me that you can give bad tools to a good machinist and they will still be a good machinist and make good parts but you can give a bad machinist good tools and they will still be bad machinists. Too many posters here consider these hobby level machines to be bad machines.

Vector layout of the Lords Prayer Cross "Our Father" for CNC machines. (Laser machines, milling, plasma)-----The following file formats are provided:. CDR. SVG. EPS. DXF . PNG The digital product includes CDR (CorelDraw) files and SVG and DXF and PNG. The text is the Lord's Prayer (Our Father) modern version: "Our Father in heaven, hallowed be . With CNC machine tools, there is the Father of all Machines, the Double Column Machining Center (DCMC). From this one machine type all other machines are built, whether it be a CNC lathe or a machining center. All CNC machine frame or bed construction is machined on a large double column machining center that can range in size from 1.6 meters .You’ll find a wide selection of used CNC machines from top brands that match your business needs and budget in every CNC auction we host. With more than 70 employees, we have over 270 years of combined experience in auctions, metalworking, process, plastics, and packaging equipment. We’re proud of the business and reputation we’ve built .

first numerical control machine

Study with Quizlet and memorize flashcards containing terms like A drill press is more accurate than a milling machine., In a lathe, the material is often secured in a set of jaws called a _____., The _____ is the most versatile manual piece of manufacturing equipment. and more.

TYPES OF CNC MACHINES CNC machines will have movement that is either linear, or straight line, in motion or rotational. Typically the X, Y and Z axis are used for linear movements, whereas A, B or C will correspond to rotational axis, with A rotating about the X axis, B about the Y axis, and C about the Z axis. CNC machine designs will vary . And in 1975, the Society of Manufacturing Engineers awarded him a plaque naming him ‘The Father of the Second Industrial Revolution.’” . This is exactly what happens in a modern CNC machine. The way it was used in early NC machines was, instead of a pilot moving a lever, the lever would ride on a cam that would move it back and forth . Before NC machines, manufacturing machines used manual controls, which had to be adjusted to tell the device where to act, such as a cut, punch, etc. Mr. John T. Parsons was the father of NC . #Types of CNC Machine , parts of cnc machine, Father of CNC machine , Numerical control machine,# History of CNC machine ,CNC turning machine,#VMC machine ,H.

moving junction box in concrete ceiling

mukhwas box steel

To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a torch, furnace, or induction heater. It provides strong, durable joints that are resistant to corrosion and wear.

father of cnc machine|first nc machine