camber in sheet metal Variation of sheet thickness along with its width is called camber. The following three types of cambers are observed on rolled sheets. These are illustrated in Fig. 8.22. (i) Convex—Sheet is .

Grind the tungsten tip to a sharp point to weld steel, and use either ER70S-2 filler metal or a silicon bronze rod. You need little heat to melt silicon bronze, making it one of the most popular filler metals for fragile, thin steel sheets.

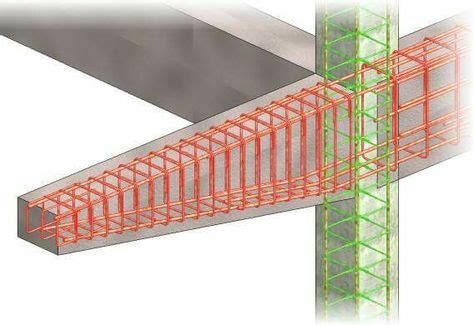

0 · prechamber beam

1 · precamber meaning

2 · pre camber beam

3 · heat cambering steel beams

4 · cambered steel beam

5 · camber meaning in construction

6 · camber in structural steel

7 · camber in construction

Since stainless steel is high in density, welding with flux core will provide a high deposition rate, especially with such styles as MIG welding with flux core wire, as they are quicker and easier to accomplish.

prechamber beam

In rolled metal, camber is a curve across the plane of the sheet, whether down the middle or along one or both edges. Camber is measured by putting a straight edge next to the sheet. The greatest distance between the straight line and the sheet’s curve is the camber. A cambered sheet might be slightly thinner . See moreCamber is a curve in the vertical plane or strong axis (hardway bending) of a metal beam or sheet. Imagine you’re looking at a beam from one end. . See moreThe quality of coiled metal needed depends on its ultimate use. Higher-strength steel is prone to more camber issues but can be worth it in the long run. Ideally, a work roll of coiled steel should be perfectly flat. In reality, curves happen. Camber can, . See more

For four generations, Ulbrich Stainless Steels & Special Metals, Inc. has been a global leader in precision metals. We produce an array of customized materials to meet unique demands for many industries. Our ability to deliver consistent product means . See moreCamber is the measurement of a substrate’s curvature on both faces showing the deviation, bow and warp along the longest linear dimension. This is normally measured using a set of parallel plates with a gap that the substrates will pass .

cnc machined enclosure

Variation of sheet thickness along with its width is called camber. The following three types of cambers are observed on rolled sheets. These are illustrated in Fig. 8.22. (i) Convex—Sheet is . Camber refers to the deviation of a coil’s side edge measured from a straight edge, with the maximum allowable deviation from a straight edge defined in individual ASTM .

In some industrial metal rolling processes, rolls are given temporary camber by applying forces through their bearings. Another way that rolls deflect is by the shortening of their radius along .Camber is the measured deviation of the side of a sheet from a straight edge. Camber is caused by one side of a sheet being elongated more than the other side during perforation or leveling. .Hot Dipped/Metallic-Coated Sheet Over 12 Inches Wide (ASTM 924/97A) Camber is the deviation of a side edge from a straight line, the measurement being taken on the concave side with a .

Camber, in this context, refers to the deviation of a coil’s side edge from a straight edge, a crucial metric governed by individual ASTM material standards. To measure camber, a specific-length . Bending steel sections can involve both curving and cambering. In the world of structural steel, camber denotes a curve in the vertical plane; sweep denotes a curve in the horizontal plane. Steel members produced in a steel .Camber is the greatest deviation of a side edge from a straight line. The measurement is taken over the entire length of the con-cave side with a straight line. On perforated sheets with .In rolled metal, camber is a curve across the plane of the sheet, whether down the middle or along one or both edges. Camber is measured by putting a straight edge next to the sheet. The greatest distance between the straight line and the sheet’s curve is the camber.

Camber is the measurement of a substrate’s curvature on both faces showing the deviation, bow and warp along the longest linear dimension. This is normally measured using a set of parallel plates with a gap that the substrates will pass through.

Variation of sheet thickness along with its width is called camber. The following three types of cambers are observed on rolled sheets. These are illustrated in Fig. 8.22. (i) Convex—Sheet is thicker in the middle and thinner towards edges. (ii) Concave—Sheet is thinner in middle and is thicker towards edges. Camber refers to the deviation of a coil’s side edge measured from a straight edge, with the maximum allowable deviation from a straight edge defined in individual ASTM material standards. Measure camber by placing a specific-length straight edge against the concave edge of the coil strip and measuring the maximum distance between the sheet .In some industrial metal rolling processes, rolls are given temporary camber by applying forces through their bearings. Another way that rolls deflect is by the shortening of their radius along the contact of the work.Camber is the measured deviation of the side of a sheet from a straight edge. Camber is caused by one side of a sheet being elongated more than the other side during perforation or leveling. Camber often results from having unequal side margins on a sheet.

Hot Dipped/Metallic-Coated Sheet Over 12 Inches Wide (ASTM 924/97A) Camber is the deviation of a side edge from a straight line, the measurement being taken on the concave side with a straightedge. The camber tolerances for sheet in cut lengths, not resquared, are as shown in this table. Cut Length Thru 4 incl. 4 Thru 6 incl. Over 6 Thru 8 incl.Camber, in this context, refers to the deviation of a coil’s side edge from a straight edge, a crucial metric governed by individual ASTM material standards. To measure camber, a specific-length straight edge is placed against the concave edge of the coil strip. Bending steel sections can involve both curving and cambering. In the world of structural steel, camber denotes a curve in the vertical plane; sweep denotes a curve in the horizontal plane. Steel members produced in a steel mill .

Camber is the greatest deviation of a side edge from a straight line. The measurement is taken over the entire length of the con-cave side with a straight line. On perforated sheets with different side margins (e-2>e-1) it is possible to produce a camber effect.In rolled metal, camber is a curve across the plane of the sheet, whether down the middle or along one or both edges. Camber is measured by putting a straight edge next to the sheet. The greatest distance between the straight line and the sheet’s curve is the camber.

precamber meaning

pre camber beam

Camber is the measurement of a substrate’s curvature on both faces showing the deviation, bow and warp along the longest linear dimension. This is normally measured using a set of parallel plates with a gap that the substrates will pass through.

Variation of sheet thickness along with its width is called camber. The following three types of cambers are observed on rolled sheets. These are illustrated in Fig. 8.22. (i) Convex—Sheet is thicker in the middle and thinner towards edges. (ii) Concave—Sheet is thinner in middle and is thicker towards edges. Camber refers to the deviation of a coil’s side edge measured from a straight edge, with the maximum allowable deviation from a straight edge defined in individual ASTM material standards. Measure camber by placing a specific-length straight edge against the concave edge of the coil strip and measuring the maximum distance between the sheet .In some industrial metal rolling processes, rolls are given temporary camber by applying forces through their bearings. Another way that rolls deflect is by the shortening of their radius along the contact of the work.Camber is the measured deviation of the side of a sheet from a straight edge. Camber is caused by one side of a sheet being elongated more than the other side during perforation or leveling. Camber often results from having unequal side margins on a sheet.

Hot Dipped/Metallic-Coated Sheet Over 12 Inches Wide (ASTM 924/97A) Camber is the deviation of a side edge from a straight line, the measurement being taken on the concave side with a straightedge. The camber tolerances for sheet in cut lengths, not resquared, are as shown in this table. Cut Length Thru 4 incl. 4 Thru 6 incl. Over 6 Thru 8 incl.Camber, in this context, refers to the deviation of a coil’s side edge from a straight edge, a crucial metric governed by individual ASTM material standards. To measure camber, a specific-length straight edge is placed against the concave edge of the coil strip.

Bending steel sections can involve both curving and cambering. In the world of structural steel, camber denotes a curve in the vertical plane; sweep denotes a curve in the horizontal plane. Steel members produced in a steel mill .

cnc machined micro pen

Relationship based commercial Sheet Metal company specializing in commercial construction. We are a relationship based Local 104 Architectural Sheet Metal contractor that services the .

camber in sheet metal|heat cambering steel beams