bearings used in cnc machines Mechanical bearings are crucial components in CNC machines, playing a vital role in their operation and performance. Their importance can be understood through three key aspects: CNC machines require precise, controlled movements to produce accurate parts. Bearings facilitate these movements by reducing friction between moving components.

Throughout 2023, China exported metalworking machinery to Russia valued at $390 million, a fourfold increase compared to $94 million in 2022. This surge underscores the .

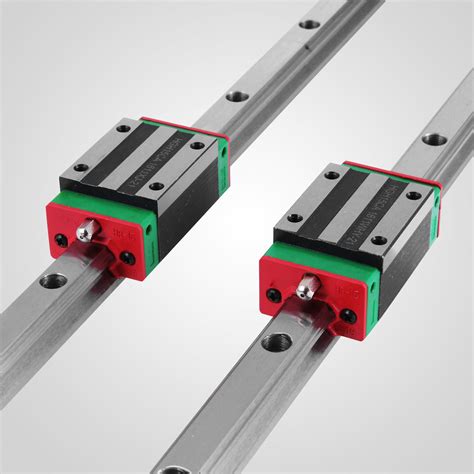

0 · linear rail and bearing block

1 · cnc supply store near me

2 · cnc machine bearing

3 · cheap linear bearings and rails

4 · cbc bearings near me

5 · cbc bearings catalogue

6 · cbc bearing company

7 · 1 2 inch linear bearing

$15.99

Understanding the types of CNC bearings, their functions, and how to apply them in your CNC operation is crucial for your production success. Different bearings work on different CNC equipment, making it essential for you to choose them carefully.CNC machine spindle bearings are crucial components for ensuring the accuracy, precision, and longevity of CNC machines. By understanding the importance, types, features, maintenance .

Understanding the types of CNC bearings, their functions, and how to apply them in your CNC operation is crucial for your production success. Different bearings work on different CNC equipment, making it essential for you to choose them carefully.CNC machine spindle bearings are crucial components for ensuring the accuracy, precision, and longevity of CNC machines. By understanding the importance, types, features, maintenance tips, and troubleshooting techniques for spindle bearings, operators and manufacturers can optimize their CNC machine's performance and reduce downtime. Bearings are crucial parts that direct and enhance spindle movement. The use of high quality bearings, improves the efficiency and reliability of machine tool spindles, thereby increasing production and reducing wear and tear on machinery. Mechanical bearings are crucial components in CNC machines, playing a vital role in their operation and performance. Their importance can be understood through three key aspects: CNC machines require precise, controlled movements to produce accurate parts. Bearings facilitate these movements by reducing friction between moving components.

linear rail and bearing block

Precision Angular Contact Bearings - also known as Spindle Bearings - and are most often used in the main Spindle of CNC Machines and other Machine Tools. They can accommodate heavy axial loads at high speeds while maintaining running accuracy. CNC machines employ bearings to minimize friction between different parts to enhance efficiency. Since bearings can accommodate radial and axial loads, they decrease wear, vibration, and functionality issues. The choice of the bearing depending on the load, speed, and conditions of operation is one In CNC machining services, bearings play an essential role in ensuring the accuracy and performance of rotating parts. Key Functions of Bearings: Reduce Friction: Bearings facilitate rolling instead of sliding, which significantly reduces the friction between moving parts.

Explore LILY Bearing's guide on spindle bearings for CNC machining. Improve precision and efficiency with the right bearing choice.High-quality bearings are a critical component in CNC machines, significantly impacting performance, precision, durability, and efficiency. Investing in high-quality bearings and implementing proper maintenance practices can enhance the productivity of CNC machines and extend their lifespan.High rigidity thrust bearings designed specifically for ball screw support applications in machine tools. › Contact angle: 60˚ › Can be universally matched to any required rigidity specification or life cycleUnderstanding the types of CNC bearings, their functions, and how to apply them in your CNC operation is crucial for your production success. Different bearings work on different CNC equipment, making it essential for you to choose them carefully.

CNC machine spindle bearings are crucial components for ensuring the accuracy, precision, and longevity of CNC machines. By understanding the importance, types, features, maintenance tips, and troubleshooting techniques for spindle bearings, operators and manufacturers can optimize their CNC machine's performance and reduce downtime. Bearings are crucial parts that direct and enhance spindle movement. The use of high quality bearings, improves the efficiency and reliability of machine tool spindles, thereby increasing production and reducing wear and tear on machinery. Mechanical bearings are crucial components in CNC machines, playing a vital role in their operation and performance. Their importance can be understood through three key aspects: CNC machines require precise, controlled movements to produce accurate parts. Bearings facilitate these movements by reducing friction between moving components.

Precision Angular Contact Bearings - also known as Spindle Bearings - and are most often used in the main Spindle of CNC Machines and other Machine Tools. They can accommodate heavy axial loads at high speeds while maintaining running accuracy. CNC machines employ bearings to minimize friction between different parts to enhance efficiency. Since bearings can accommodate radial and axial loads, they decrease wear, vibration, and functionality issues. The choice of the bearing depending on the load, speed, and conditions of operation is one

In CNC machining services, bearings play an essential role in ensuring the accuracy and performance of rotating parts. Key Functions of Bearings: Reduce Friction: Bearings facilitate rolling instead of sliding, which significantly reduces the friction between moving parts.

Explore LILY Bearing's guide on spindle bearings for CNC machining. Improve precision and efficiency with the right bearing choice.High-quality bearings are a critical component in CNC machines, significantly impacting performance, precision, durability, and efficiency. Investing in high-quality bearings and implementing proper maintenance practices can enhance the productivity of CNC machines and extend their lifespan.

cnc supply store near me

cnc machine bearing

cheap linear bearings and rails

des moines metal fabricating northeast broadway avenue des moines ia

92 E250 fuse box location? Jump to Latest Follow 1K views 1 reply 2 participants last post by toalpi May 22, 2004. M. Mr_Roboto Discussion starter 4723 posts

bearings used in cnc machines|1 2 inch linear bearing