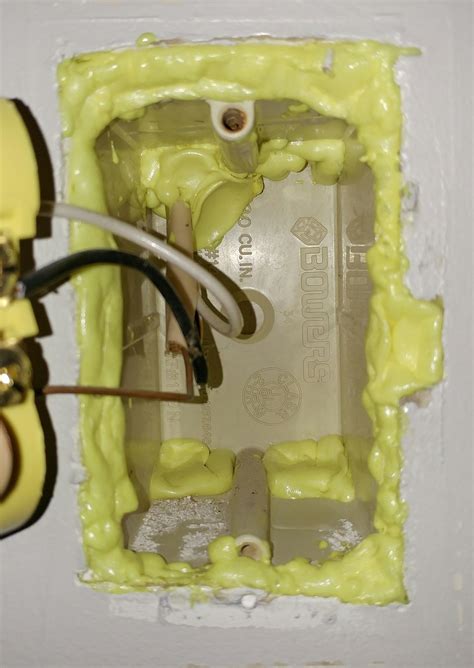

electric code foam in outlet box If the box is between the foam and any arcs that might occur, the box should protect the foam. Items in the box (wiring, devices, etc) must be fire resistant, but not necessarily fire proof. They are tested To withstand a certain .

The electrical box on the outside of a house is typically called an “electric meter box” or a “meter base”. It is used to house the electrical meter, which is the device used to measure the amount of electricity a home uses.

0 · spray foam inside outlet

1 · spray foam inside electrical box

2 · spray foam in outlet box

3 · spray foam in electrical outlet

4 · foam inside electrical outlet

5 · foam in electrical outlet box

6 · fire foam inside electrical box

The first, and most common, and nearest to densely populated areas is a vent box. This is a round cast iron plumbing cover with louvers about 6″ in diameter. Typically, they are black but often get painted. They are flush with concrete or .

The proper thing to use is the foam gaskets that fit between the device and the cover plate. Thermal insulation material shall not be sprayed or otherwise introduced into the interior of outlet boxes, junction boxes, or enclosures for other electrical equipment. I'm . Does anyone have any code reference as to why you should not use spray foam insulation inside boxes to seal them? I've been discussing this with a DIYer and he seems to .

The issue is that expanding foam is pretty flammable, and one of the main purposes of the electrical box is to contain any unexpected heat or sparks in the box. By . The electrical code forbids you from filling the air in the box with spray foam. You've done a pretty good job of keeping the foam out of the box. As long as you don't let the foam encroach on the volume of the box, everything . Before installing electrical outlets, learn about the electrical code for outlets in fire-rated walls. Complying with the 24 in. rule is easy with this guide!

If the box is between the foam and any arcs that might occur, the box should protect the foam. Items in the box (wiring, devices, etc) must be fire resistant, but not necessarily fire proof. They are tested To withstand a certain . The small air gaps around electrical boxes on exterior walls and ceilings leak more air than you might imagine. Achieve better foam outlet insulation with these simple tips.

*Can I use spray expansion foam around the metal outlet inside the wall to reduce loss of heat, WITHOUT risking catching fire. Like said before older home 60’s/70’s with paneling painted .

The proper thing to use is the foam gaskets that fit between the device and the cover plate. Thermal insulation material shall not be sprayed or otherwise introduced into the interior of outlet boxes, junction boxes, or enclosures for other electrical equipment. I'm working on a remodel house and the owner has hired an energy super saver company. Does anyone have any code reference as to why you should not use spray foam insulation inside boxes to seal them? I've been discussing this with a DIYer and he seems to think it's a best practice to fill up most of the box with foam after he has all of his wire run. The issue is that expanding foam is pretty flammable, and one of the main purposes of the electrical box is to contain any unexpected heat or sparks in the box. By adding foam in the box, you're adding burnable material.

The electrical code forbids you from filling the air in the box with spray foam. You've done a pretty good job of keeping the foam out of the box. As long as you don't let the foam encroach on the volume of the box, everything should be OK. Don't worry about the caulk.

Before installing electrical outlets, learn about the electrical code for outlets in fire-rated walls. Complying with the 24 in. rule is easy with this guide! If the box is between the foam and any arcs that might occur, the box should protect the foam. Items in the box (wiring, devices, etc) must be fire resistant, but not necessarily fire proof. They are tested To withstand a certain amount of arcing and certain temperatures for certain durations. The small air gaps around electrical boxes on exterior walls and ceilings leak more air than you might imagine. Achieve better foam outlet insulation with these simple tips. *Can I use spray expansion foam around the metal outlet inside the wall to reduce loss of heat, WITHOUT risking catching fire. Like said before older home 60’s/70’s with paneling painted and low R value original insulation in the walls.

You could insulate your walls with open cell spray foam, and it could go right against the Romex and junction boxes as long as it doesn't go inside. It is safer to use caulk, of course. It's probably easier to control too.

The actual safe way to do this is to use fire rated expanding foam (usually red/orange in color) and go around any gaps on the outside of the electrical box, ie if there is a gap between the drywall and the electrical box, you fill it with foam, not the inside of the box. The proper thing to use is the foam gaskets that fit between the device and the cover plate. Thermal insulation material shall not be sprayed or otherwise introduced into the interior of outlet boxes, junction boxes, or enclosures for other electrical equipment. I'm working on a remodel house and the owner has hired an energy super saver company. Does anyone have any code reference as to why you should not use spray foam insulation inside boxes to seal them? I've been discussing this with a DIYer and he seems to think it's a best practice to fill up most of the box with foam after he has all of his wire run.

The issue is that expanding foam is pretty flammable, and one of the main purposes of the electrical box is to contain any unexpected heat or sparks in the box. By adding foam in the box, you're adding burnable material.

The electrical code forbids you from filling the air in the box with spray foam. You've done a pretty good job of keeping the foam out of the box. As long as you don't let the foam encroach on the volume of the box, everything should be OK. Don't worry about the caulk.

Before installing electrical outlets, learn about the electrical code for outlets in fire-rated walls. Complying with the 24 in. rule is easy with this guide! If the box is between the foam and any arcs that might occur, the box should protect the foam. Items in the box (wiring, devices, etc) must be fire resistant, but not necessarily fire proof. They are tested To withstand a certain amount of arcing and certain temperatures for certain durations. The small air gaps around electrical boxes on exterior walls and ceilings leak more air than you might imagine. Achieve better foam outlet insulation with these simple tips.

*Can I use spray expansion foam around the metal outlet inside the wall to reduce loss of heat, WITHOUT risking catching fire. Like said before older home 60’s/70’s with paneling painted and low R value original insulation in the walls.You could insulate your walls with open cell spray foam, and it could go right against the Romex and junction boxes as long as it doesn't go inside. It is safer to use caulk, of course. It's probably easier to control too.

spray foam inside outlet

mild steel box section stockists

mig welding 18 gauge sheet metal

The sturdy sheet metal body and angled cast aluminum wire drive are of better build quality than most entry-level welders. However, missing features like DINSE connectors, dual-voltage input, digital display, and advanced arc control make the Easy MIG 180 overpriced by today’s standards.

electric code foam in outlet box|foam in electrical outlet box