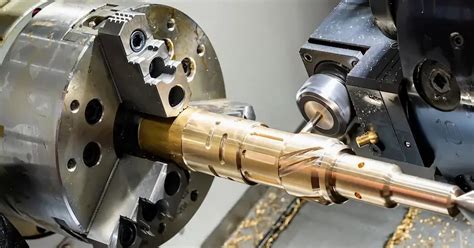

cnc machine outsource services As a widely embraced strategy for businesses across industries and a sought-after solution for various manufacturing needs, CNC machining outsourcing helps revolutionize your production process at reduced costs. Drill bits are used in a variety of projects, from creating pilot holes in wood to prevent splitting, to installing drywall anchors to prevent shelves from falling down. But if you choose the wrong size, you may be doing more harm than good! Determining the right drill bit size comes down to three factors: the dimensions of your screws, the type of hole you're drilling, .Your pilot-hole drill bit size will depend on the size of your sheet-metal screw. A size-4 screw should have a pilot-hole drill size of 3/32 inches; size 6, 7/64 inches; size 8, 1/8 .

0 · CNC Machining Outsourcing: Benefits and Expert Tips

1 · CNC Machining Outsourcing: A Comprehensive Guide

A waterproof junction box or plastic weatherproof electrical box keeps wirings safe and secure. Here’s why using a junction box outdoors is important. We’ll also give tips on, how to pick the right one and more.

CNC Machining Outsourcing: Benefits and Expert Tips

Learn about CNC machining outsourcing benefits, best practices, and considerations. Reduce costs and improve quality by outsourcing your CNC to Fictiv. As a widely embraced strategy for businesses across industries and a sought-after solution for various manufacturing needs, CNC machining outsourcing helps revolutionize your production process at reduced costs.Learn about CNC machining outsourcing benefits, best practices, and considerations. Reduce costs and improve quality by outsourcing your CNC to Fictiv.

As a widely embraced strategy for businesses across industries and a sought-after solution for various manufacturing needs, CNC machining outsourcing helps revolutionize your production process at reduced costs.

Outsourcing your CNC machining services to WayKen provides precision, flexibility, and excellent quality control, ensuring your projects are completed with expected results. With a team of experienced specialists, WayKen can streamline production while reducing costs, offering you the chance to focus on other business priorities. Enjoy .

If you wish to increase your manufacturing, outsourcing CNC machining services might be quite beneficial. Many advantages include cost savings, strict control over quality, faster production, and ease of business expansion.At Aerostar Manufacturing, we excel in providing Outsourced CNC Machining services that cater to a global clientele. Our state-of-the-art facilities and expert team ensure that we deliver unparalleled quality and precision in every project.By outsourcing CNC machining services, businesses eliminate the costs associated with maintaining an in-house machining facility. This includes machinery expenses, equipment maintenance, staff training, and overhead.

Founded in 1987, P.D. Peterka grew from a small machine shop to a fully equipped outsource manufacturing facility. Located in the USA for all of your outsource manufacturing needs. Machining services range from CNC machine capabilities to intricate manual machining for retrofitting of parts.

This article outlines the benefits of outsourcing CNC machining services and how to choose the right vendor. You’d find this guide helpful whether you’re looking for a general manufacturing partner for your small business’s products or a one-stop aerospace machining shop for your aviation business.At Sun Fast, we specialize in strategic sourcing to provide OEMS with an alternative to costly CNC machining services. Our CNC precision machining outsourcing options provide the results you require without having to make a significant economic investment on the purchasing of machines, staff and space.

This article will discuss how outsourcing CNC machining services for your company’s prototype design is beneficial, explain why CNC machining is a practical choice for prototyping, and guide what to consider when selecting .Learn about CNC machining outsourcing benefits, best practices, and considerations. Reduce costs and improve quality by outsourcing your CNC to Fictiv. As a widely embraced strategy for businesses across industries and a sought-after solution for various manufacturing needs, CNC machining outsourcing helps revolutionize your production process at reduced costs. Outsourcing your CNC machining services to WayKen provides precision, flexibility, and excellent quality control, ensuring your projects are completed with expected results. With a team of experienced specialists, WayKen can streamline production while reducing costs, offering you the chance to focus on other business priorities. Enjoy .

If you wish to increase your manufacturing, outsourcing CNC machining services might be quite beneficial. Many advantages include cost savings, strict control over quality, faster production, and ease of business expansion.At Aerostar Manufacturing, we excel in providing Outsourced CNC Machining services that cater to a global clientele. Our state-of-the-art facilities and expert team ensure that we deliver unparalleled quality and precision in every project.

CNC Machining Outsourcing: A Comprehensive Guide

By outsourcing CNC machining services, businesses eliminate the costs associated with maintaining an in-house machining facility. This includes machinery expenses, equipment maintenance, staff training, and overhead.Founded in 1987, P.D. Peterka grew from a small machine shop to a fully equipped outsource manufacturing facility. Located in the USA for all of your outsource manufacturing needs. Machining services range from CNC machine capabilities to intricate manual machining for retrofitting of parts.This article outlines the benefits of outsourcing CNC machining services and how to choose the right vendor. You’d find this guide helpful whether you’re looking for a general manufacturing partner for your small business’s products or a one-stop aerospace machining shop for your aviation business.At Sun Fast, we specialize in strategic sourcing to provide OEMS with an alternative to costly CNC machining services. Our CNC precision machining outsourcing options provide the results you require without having to make a significant economic investment on the purchasing of machines, staff and space.

4.3. Hot Working Mechanical working processes which are done above recrystallisation temperature of the metal are know as hot working processes. Some metals, such as lead and tin, have a low recrystallisation temperature and can be hot-worked even at room temperature, but most commercial metals require some heating. However, this

cnc machine outsource services|CNC Machining Outsourcing: A Comprehensive Guide