chemicals used in metal fabrication To produce high-quality steel efficiently and safely, various chemicals are used throughout the manufacturing process. These chemicals .

Polycase offers hundreds of weatherproof box models in different shapes, sizes, styles, and NEMA/IP ratings. From 304 stainless steel to polycarbonate plastic with a fiberglass reinforced base, we provide a broad range of durable material choices.

0 · protolabs metal fabrication guide

1 · how to manufacture sheet metal

2 · how to manufacture metal parts

3 · how to manufacture metal

4 · chemicals used in steel manufacturing

5 · chemicals used in metal manufacturing

6 · chemicals used in metal forming

7 · chemicals used in dry steel

The WEATHER GUARD Model 175-3-04 is a 56 inch steel truck tool box for full size .

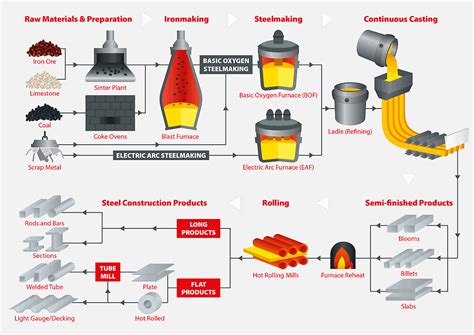

The potential for cross-contamination of chemicals through the supply chain begins in the steel production and preparation process, where we start with a hot-rolled sheet product. Dry steel is either coiled dry or acid-pickled, rinsed, dried, and coiled. Coated steel is either acid-pickled, rinsed, dried, coated, and coiled or . See more

cnc machine bits supplier

Chemists generalize and assume that materials with like chemical structures will. In fact, this is the basic principle that the development and . See moreTo understand how the amount and type of oil applied to a coil affects it as it moves through a welded tube mill, consider the following scenarios: 1. Excessive Quantity of Mill Oil.Excessive use of mill oils causes slipping of the coil as it is fed into the mill. The excessive oil . See moreLet's use welded tube as an example of steel moving from coil to finished product. A chart showing the ideal use of chemicals used in the production of a welded steel tube might look similar to that in Figure 1. As we can see, at each stage of the process we contend . See more

protolabs metal fabrication guide

Water-diluted chemicals continue to be used widely in a variety of forming and fabricating operations for a variety of reasons. A few of . See more To produce high-quality steel efficiently and safely, various chemicals are used throughout the manufacturing process. These chemicals .

Learn about the material properties of hard and soft metals as well as the machining, molding, and 3D printing processes used to manufacture metal parts. Understanding Steel Fabrication. Steel fabrication is the process of reshaping raw steel into the final product using various techniques. It involves cutting, bending, welding, machining, and assembling the steel components to .When you order fabricated metal structures, the appropriate metals are then cut, bent or assembled to suit your needs. Whether you require parts with corrosion resistance, enhanced strength or a silvery polish, there is a common metal . Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. Aluminum advantages: Lightweight: Great for applications where .

how to manufacture sheet metal

how to manufacture metal parts

Depending on the products you fabricate, you might need to integrate some kind of blasting system to prepare the surface for optimal paint adhesion. If an aqueous pretreatment .

As a subtractive manufacturing process, chemical etching removes metal from a workpiece to produce parts with a specific shape and thickness. Temperature-regulated etching chemicals .

The materials used in industrial sheet metal fabrication form the backbone of its versatility and functionality. Steel, aluminum, copper, brass, and galvanized steel are just a few examples of the wide range of options available.

Lubricants, coolants, corrosion inhibitors, cleaners, coatings, fluxes, and other chemicals all are used-and thus intermixed-in metal manufacturing, forming, fabrication, welding, and finishing. To produce high-quality steel efficiently and safely, various chemicals are used throughout the manufacturing process. These chemicals play vital roles in refining, treating, and coating steel to enhance its properties and performance.Learn about the material properties of hard and soft metals as well as the machining, molding, and 3D printing processes used to manufacture metal parts. Learn about the six imperative materials used in sheet metal fabrication. Discover their properties, applications and importance in the manufacturing process.

Understanding Steel Fabrication. Steel fabrication is the process of reshaping raw steel into the final product using various techniques. It involves cutting, bending, welding, machining, and assembling the steel components to meet client specs.When you order fabricated metal structures, the appropriate metals are then cut, bent or assembled to suit your needs. Whether you require parts with corrosion resistance, enhanced strength or a silvery polish, there is a common metal and .

Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. Aluminum advantages: Lightweight: Great for applications where weight reduction is key, such as in automotive and aerospace industries. Depending on the products you fabricate, you might need to integrate some kind of blasting system to prepare the surface for optimal paint adhesion. If an aqueous pretreatment (chemical) process is used, the parts need to be dried. That is followed by the actual coating process and, finally, curing.

As a subtractive manufacturing process, chemical etching removes metal from a workpiece to produce parts with a specific shape and thickness. Temperature-regulated etching chemicals are used within the process to fuel this result. The materials used in industrial sheet metal fabrication form the backbone of its versatility and functionality. Steel, aluminum, copper, brass, and galvanized steel are just a few examples of the wide range of options available. Lubricants, coolants, corrosion inhibitors, cleaners, coatings, fluxes, and other chemicals all are used-and thus intermixed-in metal manufacturing, forming, fabrication, welding, and finishing.

To produce high-quality steel efficiently and safely, various chemicals are used throughout the manufacturing process. These chemicals play vital roles in refining, treating, and coating steel to enhance its properties and performance.

how to manufacture metal

Learn about the material properties of hard and soft metals as well as the machining, molding, and 3D printing processes used to manufacture metal parts. Learn about the six imperative materials used in sheet metal fabrication. Discover their properties, applications and importance in the manufacturing process. Understanding Steel Fabrication. Steel fabrication is the process of reshaping raw steel into the final product using various techniques. It involves cutting, bending, welding, machining, and assembling the steel components to meet client specs.When you order fabricated metal structures, the appropriate metals are then cut, bent or assembled to suit your needs. Whether you require parts with corrosion resistance, enhanced strength or a silvery polish, there is a common metal and .

Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. Aluminum advantages: Lightweight: Great for applications where weight reduction is key, such as in automotive and aerospace industries.

Depending on the products you fabricate, you might need to integrate some kind of blasting system to prepare the surface for optimal paint adhesion. If an aqueous pretreatment (chemical) process is used, the parts need to be dried. That is followed by the actual coating process and, finally, curing.As a subtractive manufacturing process, chemical etching removes metal from a workpiece to produce parts with a specific shape and thickness. Temperature-regulated etching chemicals are used within the process to fuel this result.

chemicals used in steel manufacturing

The 4 lockable latches and soft rubber seals make the box IP54 Weatherproof. Wide Compatible: Large size outdoor electrical box(12.5 x 8.5 x 5 inches) which can protect your power strip, timer outlet, bulky adapter and more outdoor/indoor electrical connections. The 6 cable seal ports can allow maximum 6 cords input/output.

chemicals used in metal fabrication|chemicals used in metal manufacturing