create sheet metal part that will fit around part Where possible, design parts to be self locating, minimizing the need for jigs and fixtures during assembly. With sheet metal in particular, using PEM inserts or rivets instead of welding can save signficant time and money if functionality . Our round pens can be customized to any size you need. House any number of animals with customized stalls. We've got the product and solution for you. However and wherever you want to work your animals, we've got you .

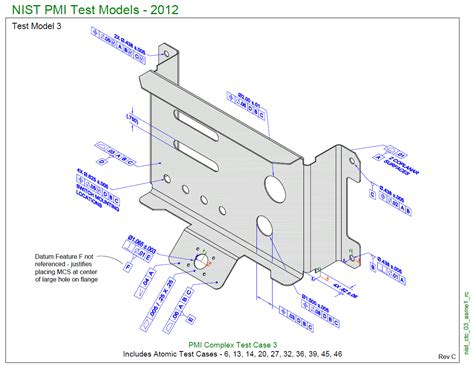

0 · sheet metal parts drawings

1 · sheet metal parts design problems

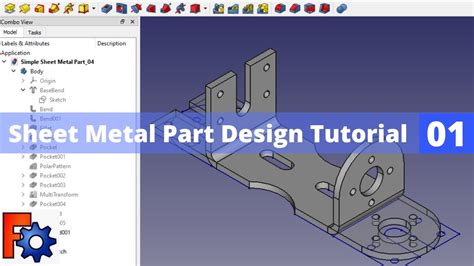

2 · sheet metal parts design

3 · sheet metal design

4 · making sheet metal parts

5 · how to design sheet metal

6 · flat sheet metal design

7 · designing sheet metal corners

Surface Finish-Precision Aluminum Parts - CNC Machined Components. USD 100 / Piece . Get Best price. Country of Origin: China : MOQ: 1 Piece : Price: USD 100 / Piece: Category: Machinery & Industrial Supplies Metallurgy Machinery & Parts: Contact Surface Finish-Precision Aluminum Parts supplier for wholesale b2b price, customization or other .

Ideally, engineers could design sheet metal in a manufacturing-first platform: modeled features would be tested against tools and machines automatically, with design .Where possible, design parts to be self locating, minimizing the need for jigs and fixtures during assembly. With sheet metal in particular, using PEM inserts or rivets instead of welding can save signficant time and money if functionality .In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. Sheet metal parts require a sequence of manufacturing processes to . How to Design Sheet Metal Parts in 5 Easy Steps Step 1: Determine the Purpose of the Sheet Metal Part. Before starting to design a sheet metal part, it is important to clearly determine its purpose. This includes .

Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in .

With the new Joggle command, complex joggles can be created on tabs and flanges. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset (joggled) region via transition, with run . Design and make edits to imported sheet metal parts as if they were native geometry—by simply dragging features like tabs or flanges—without remodeling. Solid Edge provides unmatched model validation to ensure manufacturability and reduce the need for physical .

If you’re designing a part with an awkward size or shape that does not fit well on standard sheets, or a part with large cutout features—you may end up paying extra money for wasted material. Our typical solution for this .In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing .Sheet metal is flat and must be bent, formed, cut, lased, and sometimes cajoled into its final shape. It’s a very hands-on process. If you design your sheet metal part as a solid object, it’s important that you send us a CAD file that appears folded, but shows where bends should go. Ideally, engineers could design sheet metal in a manufacturing-first platform: modeled features would be tested against tools and machines automatically, with design feedback available instantaneously, or at least as fast as it takes the DFM to run.

sheet metal parts drawings

Where possible, design parts to be self locating, minimizing the need for jigs and fixtures during assembly. With sheet metal in particular, using PEM inserts or rivets instead of welding can save signficant time and money if functionality permits. Sheet metal design reviews and drawing preparation. As with any design, mistakes are inevitable.In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. Sheet metal parts require a sequence of manufacturing processes to transition from raw stock material to finished part. How to Design Sheet Metal Parts in 5 Easy Steps Step 1: Determine the Purpose of the Sheet Metal Part. Before starting to design a sheet metal part, it is important to clearly determine its purpose. This includes understanding its function and how it fits into the overall product or project.

Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in sheet metal fabrication, serving as a measure of the acceptable variation between the initial design and the final product. With the new Joggle command, complex joggles can be created on tabs and flanges. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset (joggled) region via transition, with run-out . Design and make edits to imported sheet metal parts as if they were native geometry—by simply dragging features like tabs or flanges—without remodeling. Solid Edge provides unmatched model validation to ensure manufacturability and reduce the need for physical prototypes. If you’re designing a part with an awkward size or shape that does not fit well on standard sheets, or a part with large cutout features—you may end up paying extra money for wasted material. Our typical solution for this problem is to split the design into two pieces and weld those pieces together after cutting to make better use of the .

In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing sheet metal designs. With Onshape, users can simultaneously create and preview flat patterns.

Sheet metal is flat and must be bent, formed, cut, lased, and sometimes cajoled into its final shape. It’s a very hands-on process. If you design your sheet metal part as a solid object, it’s important that you send us a CAD file that appears folded, but shows where bends should go.

Ideally, engineers could design sheet metal in a manufacturing-first platform: modeled features would be tested against tools and machines automatically, with design feedback available instantaneously, or at least as fast as it takes the DFM to run.Where possible, design parts to be self locating, minimizing the need for jigs and fixtures during assembly. With sheet metal in particular, using PEM inserts or rivets instead of welding can save signficant time and money if functionality permits. Sheet metal design reviews and drawing preparation. As with any design, mistakes are inevitable.

plastic power distribution box

In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. Sheet metal parts require a sequence of manufacturing processes to transition from raw stock material to finished part. How to Design Sheet Metal Parts in 5 Easy Steps Step 1: Determine the Purpose of the Sheet Metal Part. Before starting to design a sheet metal part, it is important to clearly determine its purpose. This includes understanding its function and how it fits into the overall product or project. Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in sheet metal fabrication, serving as a measure of the acceptable variation between the initial design and the final product.

plastic junction boxes crumbling

With the new Joggle command, complex joggles can be created on tabs and flanges. This allows the sheet metal parts to fit around each other in assembly, with the stationary to offset (joggled) region via transition, with run-out . Design and make edits to imported sheet metal parts as if they were native geometry—by simply dragging features like tabs or flanges—without remodeling. Solid Edge provides unmatched model validation to ensure manufacturability and reduce the need for physical prototypes. If you’re designing a part with an awkward size or shape that does not fit well on standard sheets, or a part with large cutout features—you may end up paying extra money for wasted material. Our typical solution for this problem is to split the design into two pieces and weld those pieces together after cutting to make better use of the .

sheet metal parts design problems

sheet metal parts design

Creating precision cylindrical parts from steel and stainless steel sheet up to 1/4” thick - Prototype to low volume production up to 50,000 piece EAU

create sheet metal part that will fit around part|designing sheet metal corners