cast iron casting cnc parts Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Here are the basic steps involved in making cast iron: Melting the iron: The first step in making cast iron is to melt iron in a furnace at temperatures of around 2,800 degrees Fahrenheit. My metal detector goes crazy when I put it over this circular concrete slab and there's more concrete underneath. In the third picture the corner sticking out underneath the piece with the holes in it is another rectangular slab going .

0 · what is a cast iron

1 · centrifugal casting cast iron

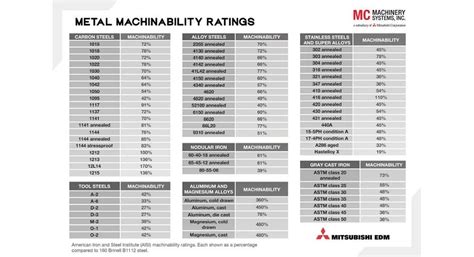

2 · cast iron machinability chart

3 · cast iron machinability

4 · cast iron investment casting

5 · cast iron in cnc

6 · cast iron continuous casting

7 · cast iron casting methods

What is a Smart Junction box, What does it do and can I replace it myself. Also where is it located in the car?

HULK Metal can provide you with excellent Casting Parts OEM services. We have a complete supply chain to custom Cast Iron Castings for you.HULK Metal can provide you with excellent Casting Parts OEM services. We have a complete supply chain to custom Cast Iron Castings for you.

Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Here are the basic steps involved in making cast iron: Melting the iron: The first step in making cast iron is to melt iron in a furnace at temperatures of around 2,800 degrees Fahrenheit.CNC cast iron machining refers to the process of using computer numerical control (CNC) technology to shape, cut, and manipulate cast iron workpieces with precision and accuracy. Cast iron is a challenging material to machine due to its hardness, abrasiveness, and .

Cast iron is a versatile metal used in various automotive components such as engine blocks, heads, flywheels, and brake rotors, as well as everyday items like household pots and road manhole covers. However, there are several types of .We’ll cover what cast iron CNC machining is, the advantages of CNC machining for cast iron parts, finishes available for cast iron parts and more. Whether you’re looking for advice on which service is right for your project or tips on how to get started, we’ve got you covered.Get any number or type of iron, ductile iron, or cast iron parts made using a variety of factory processes, including CNC machining, milling cast iron, CNC turning, and more.Optimize your application with high-value cast iron part or component manufacturing services from Lincoln Park Boring Co. Request a quote today for Lincoln Park Boring's cast iron machining services!

Gain a competitive advantage by providing your customers with finished CNC machined metal parts, or extend your in-house machining capabilities seamlessly while reducing lead times — Count on Trace-A-Matic to get the job done right the first time!

Replacing a cast iron part with steel bar. I have a part from my customer that is 6-7/16 OD, 2-1/4"ID and about 2" thick. It seems the part is a casting, but I don't want to use durabar to duplicate it. What material would you recommend it be machined from? 1018 tubing. If you can't find super-thickwall tubing, get a blank waterjet cut from plate.

Here are some tips for achieving precision CNC machining and surface finishing of cast iron parts. Choosing the right tooling and selecting the correct cutting parameters is o essential, but the selection of the proper cutting tool and machining parameters is critical when working with cast iron.HULK Metal can provide you with excellent Casting Parts OEM services. We have a complete supply chain to custom Cast Iron Castings for you.Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Here are the basic steps involved in making cast iron: Melting the iron: The first step in making cast iron is to melt iron in a furnace at temperatures of around 2,800 degrees Fahrenheit.CNC cast iron machining refers to the process of using computer numerical control (CNC) technology to shape, cut, and manipulate cast iron workpieces with precision and accuracy. Cast iron is a challenging material to machine due to its hardness, abrasiveness, and .

Cast iron is a versatile metal used in various automotive components such as engine blocks, heads, flywheels, and brake rotors, as well as everyday items like household pots and road manhole covers. However, there are several types of .We’ll cover what cast iron CNC machining is, the advantages of CNC machining for cast iron parts, finishes available for cast iron parts and more. Whether you’re looking for advice on which service is right for your project or tips on how to get started, we’ve got you covered.Get any number or type of iron, ductile iron, or cast iron parts made using a variety of factory processes, including CNC machining, milling cast iron, CNC turning, and more.Optimize your application with high-value cast iron part or component manufacturing services from Lincoln Park Boring Co. Request a quote today for Lincoln Park Boring's cast iron machining services!

Gain a competitive advantage by providing your customers with finished CNC machined metal parts, or extend your in-house machining capabilities seamlessly while reducing lead times — Count on Trace-A-Matic to get the job done right the first time! Replacing a cast iron part with steel bar. I have a part from my customer that is 6-7/16 OD, 2-1/4"ID and about 2" thick. It seems the part is a casting, but I don't want to use durabar to duplicate it. What material would you recommend it be machined from? 1018 tubing. If you can't find super-thickwall tubing, get a blank waterjet cut from plate.

what is a cast iron

centrifugal casting cast iron

cast iron machinability chart

cast iron machinability

cast iron investment casting

Article 334.30 states that cables coming out of the junction boxes should be secured within 12 inches of the box in all boxes equipped with cable clamps. These cable clamps are not to be removed. 314.17 (C) states that cables must be secured to the receptacle box.

cast iron casting cnc parts|cast iron in cnc