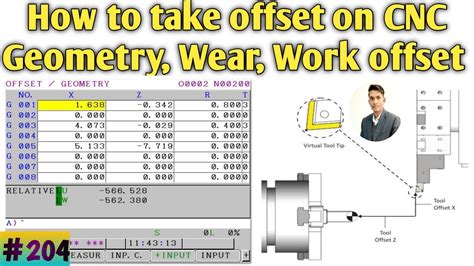

cnc machine offset setting This Tool Offsetting Routine is supported by most CNC machines. No need to face the top of your part to set your tools or work offset. Just calculate the distance between the top of the gauge and the top of your part. A dial indicator . Most do-it-yourselfers prefer plastic electrical boxes, while electricians use both metal and plastic boxes. Metal electrical boxes were used long before plastic (PVC) electrical boxes were introduced to the market.Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit runs in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box to complete grounding.

0 · what is wear offset

1 · what is tool length offset

2 · offset turning on cnc lathe

3 · offset meaning in cnc programming

4 · offset in cnc lathe

5 · geometry vs wear offsets

6 · cnc work offsets

7 · cnc tool offsets explained

$65.00

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise .

CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, . By setting your tool length the correct way (my way), the stored offset is the actual tool length and you can do a rough check with your steel ruler before proving your program. Auto tool length measurement will always give .This Tool Offsetting Routine is supported by most CNC machines. No need to face the top of your part to set your tools or work offset. Just calculate the distance between the top of the gauge and the top of your part. A dial indicator . Once you set one of these all you need do is use the G code (54 to 59) and the machine will use that offset. Each one of these G Codes represents a datum position on the machine. G0 G54 X0 Y0 (Rapid to X0 Y0 using G54)

what is wear offset

Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine.Mastering offset turning on a CNC lathe is a valuable skill that can greatly enhance your machining capabilities. By understanding how to properly set up and utilize offsets, you can . Begin by referencing your CNC machine’s manual or seeking online tutorials for guidance tailored to your specific machine model. Typically, the process involves homing the machine, setting the workpiece in place, and .

metal lunch box black and blum

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise measurement techniques, and implementing effective offset management strategies, operators can optimize their CNC machining processes.In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by.CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, machinists can achieve precise machining, eliminate .

what is tool length offset

By setting your tool length the correct way (my way), the stored offset is the actual tool length and you can do a rough check with your steel ruler before proving your program. Auto tool length measurement will always give actual tool length and so will a tool pre-setter.This Tool Offsetting Routine is supported by most CNC machines. No need to face the top of your part to set your tools or work offset. Just calculate the distance between the top of the gauge and the top of your part. A dial indicator can be used to set the Z Work Offset; A tool pre-setter can be used to set the tool offsets. Once you set one of these all you need do is use the G code (54 to 59) and the machine will use that offset. Each one of these G Codes represents a datum position on the machine. G0 G54 X0 Y0 (Rapid to X0 Y0 using G54)

Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine.Mastering offset turning on a CNC lathe is a valuable skill that can greatly enhance your machining capabilities. By understanding how to properly set up and utilize offsets, you can achieve precise results and maximize the efficiency of your turning operations.

Begin by referencing your CNC machine’s manual or seeking online tutorials for guidance tailored to your specific machine model. Typically, the process involves homing the machine, setting the workpiece in place, and then defining the work offset coordinates. Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.

Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise measurement techniques, and implementing effective offset management strategies, operators can optimize their CNC machining processes.

In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by.

CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, machinists can achieve precise machining, eliminate .

By setting your tool length the correct way (my way), the stored offset is the actual tool length and you can do a rough check with your steel ruler before proving your program. Auto tool length measurement will always give actual tool length and so will a tool pre-setter.This Tool Offsetting Routine is supported by most CNC machines. No need to face the top of your part to set your tools or work offset. Just calculate the distance between the top of the gauge and the top of your part. A dial indicator can be used to set the Z Work Offset; A tool pre-setter can be used to set the tool offsets. Once you set one of these all you need do is use the G code (54 to 59) and the machine will use that offset. Each one of these G Codes represents a datum position on the machine. G0 G54 X0 Y0 (Rapid to X0 Y0 using G54) Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine.

metal letters for outside of house

Mastering offset turning on a CNC lathe is a valuable skill that can greatly enhance your machining capabilities. By understanding how to properly set up and utilize offsets, you can achieve precise results and maximize the efficiency of your turning operations.

offset turning on cnc lathe

metal lipo charging box

metal lined key box

John T. Parsons is credited with inventing NC machines. He was awarded a contract to manufacture wooden stringers of rotor blades for the aerospace industry, and was looking for a new way to tackle the task. He teamed up with Frank Stulen shortly thereafter and they created the first NC machine.

cnc machine offset setting|what is wear offset