notching in sheet metal This metalworking process is used extensively to manipulate the size and shape of sheet metal. Notching typically requires the use of a punch . But in places like a bathroom or a wall light, if you see a red wire, it’s a good bet that the red wire is the wire that the light switch controls while the black wires are always live. So the red wire is probably the one you want for .

0 · stripping force in sheet metal

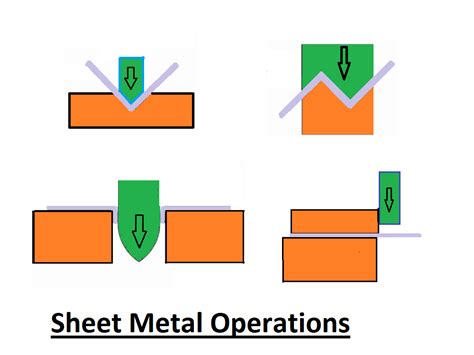

1 · slotting operation in sheet metal

2 · slitting process in sheet metal

3 · shaving operation in sheet metal

4 · protolabs sheet metal design guide

5 · parting operation in sheet metal

6 · notching process in sheet metal

7 · cutting clearance for sheet metal

An ideal coating is non-specular (to decrease geometrical effects), durable, high in reflectance and spectrally flat over a wide wavelength range to give a flat spectral response in input or output.

This metalworking process is used extensively to manipulate the size and shape of sheet metal. Notching typically requires the use of a punch .

How to Notch Sheet Metal - YouTube. House Copper & Cookware. 5.8K subscribers. 42. 2.2K views 1 year ago. After using the term "notch" and telling everyone to "notch your corners" when. Heavy Duty: Made from precision forged alloy steel, this sheet metal hand notcher works just as hard as you do. The v notcher’s compound spring design helps you easily notch sheet metal. 13/16” inch (2.1cm) . Extend ductwork, create smooth corners, and install leak proof roofing with the ABN 10 Inch Sheet Metal Notching Snips. Outfitted with self-opening handles, this set of panel notchers operates with one hand on your tool and one hand on the material.

Features: Constructed from sturdy metal, this sheet metal notcher is built to withstand rigorous use and last a long time. Its reliability reduces the need for constant replacement, making it an ideal tool for your toolbox. By blending technological prowess with robust materials, this Handy Notcher has been engineered to stay with you for years This .Baileigh Industrial is an international provider of quality metal machinery. Our proven industry leadership results in profitable solutions for your fabricating needs. Sheet Metal Notching Machines & Corner Notchers for Sale - Baileigh IndustrialUse this clamp with your 1/2 " chuck capacity drill and a hole saw to cut notches in pipe and tubing to make intersecting connections. Choose a hole saw with the same diameter as the OD of the pipe to which you are attaching the notched pipe. The clamp comes with a 1/2 "-20 arbor for use with 9/16 "-1 1/8 " diameter hole saws and a 5/8 "-18 adapter for use with 1 1/4 "-2" diameter .Sheet metal notching is a metalworking process used to create precise cuts or notches along the edges or corners of sheet metal. These notches are typically made to facilitate bending, folding, or joining of the sheet metal, allowing for the creation of clean and sharp corners in various fabricated components. 2. Advantages of Metal Notching

Notch-Cutting Bench-Mount Sheet Metal Cutters . 90° Notches. Notch, cut, and pierce a variety of materials including metal, plastic, and vinyl. These versatile cutters have an adjustable stroke length for piercing and knockout operations. Cutters. For Max. Thick. Overall. Mounting Holes. Replacement Blades. Notch Angle: Steel: Stainless Steel .Notching is a metal-cutting process used on sheet-metal or thin bar-stock, sometimes on angle sections or tube. A shearing or punching process is used in a press, so as to cut vertically down and perpendicular to the surface, working from the edge of a work-piece. Sometimes the goal is merely the notch itself, but usually this is a precursor to . The Simonds PTX-965 is the perfect handheld tool for making quick work of notching. Our notching tool handles various thicknesses and materials from straight sheet metal to meshes. We also have custom options as well. Let’s work together on this.

Twin City Sheet Metal, located in Brewer, Maine, offers customers throughout Maine design, fabrication and installation of sheet metal products including ductwork. 26 Coffin Avenue. Brewer, Maine (207) 990-5605. Tel: 207-990-5605; Home; Services. Ductwork; Laser Cutting; Bending & Forming; Fabrication; Engineering; Notching machines are specialized metal fabrication equipment designed for precision cutting of metal plates, particularly for creating notches, angles, and intricate shapes in sheet metal. There are two primary categories of notching machines: adjustable angle and fixed angle. The adjustable angle variants offer a versatile range typically . Sheet metal fabrication: Notching machines are used to notch and cut sheet metal panels and plates to create joints, tabs, and flanges in sheet metal components and assemblies. Automotive and aerospace manufacturing: Notchers are utilized in the production of automotive chassis, aircraft frames, and other specialized components that require . Notching is a type of trimming operation in sheet metal manufacturing that involves removing material from the edge of a workpiece. This operation is used when the workpiece needs to have specific shapes or patterns on its edge.

Notching sheet metal using hand tools may cause injuries and carpal tunnel for the operators. Simonds Inc. has developed a notching tool using the ergonomics.

What is A Notching Machine. A notching machine, also known as a notcher, is a specialized tool used in metalworking to create notches or cuts in metal sheets or plates.These machines typically consist of a sturdy frame with . AMERICAN MUTT TOOLS Sheet Metal Hand Notcher, Sheet Metal V Notcher – Cuts 30 Degree V Notch in Sheet Metal – Ductwork Notching Tool, Upholstery Hand Notcher, Sheet Metal Notcher, Ductwork Tools 4.2 out of 5 stars 89 Sheet metal notching errors lead to material waste, project delays, and quality issues that harm the bottom line. With proper notching techniques, manufacturers reduce scrap rates by 35% and speed up assembly time by 40%. Sheet metal notching creates precise cuts and openings in metal sheets, enabling parts to fit together seamlessly during .

stripping force in sheet metal

AMERICAN MUTT TOOLS Sheet Metal Hand Notcher, Sheet Metal V Notcher – Cuts 30 Degree V Notch in Sheet Metal – Ductwork Notching Tool, Upholstery Hand Notcher, Sheet Metal Notcher, Ductwork Tools. 4.2 out of 5 stars. 89. 50+ bought in past month. .99 $ 29. 99.Woodward Fab Manual Sheet Metal Corner Notcher SP NOTCHER. SHEET METAL CORNER NOTCHER MODEL SPNOTCHER . SHEET METAL CORNER NOTCHER MODEL SPNOTCHER . bvseo_sdk, p_sdk, 3.2.1; CLOUD, getAggregateRating, 25.61ms; REVIEWS, PRODUCT; bvseo-msg: HTTP status code of 404 was returned; $ 859.99. Loading.

Therefore, the process of sheet metal notching and bending on metal sheets came into being. Traditional Bending Methods And Their Limitations The traditional bending process is to use the two edges of the lower die opening and the edge of the upper die to bend the metal sheet under the pressure of the upper and lower dies of the bending machine .

Subject - Manufacturing Processes, MetallurgyChapter - Difference between Blanking, Piercing, Punching, Lancing, Notching Process, Sheet metal WorkingTimecod.The Di-Acro tab notcher provides an efficient means for cutting notches in regualr or tab notch combinations. Both upper & lower cutting blades are adjustable to give you any size & depth within the capacity of the metal notcher machine. Call Di-Acro® at (855) 651-8948 or (651) 342-1756 for sheet notcher machines. Hole punching is commonly used on high production sheet metal fabrication such as automotive components, airplane bodies, and decorative work. Advantages and Limitations of Notching Notching generally has the same pros and cons as hole punching as both processes use presses and rely on shear force to sever the material on which the work is .

Sheet metal notching. Email: [email protected] +86 0769 81584005 MB:86 13537204810 Blog Sitemap XML. Home; Service . Precision Laser Cutting; Sheet Metal Punching; Sheet Metal Bending; Sheet Metal Welding; Sheet Metal Drilling; Sheet Metal Tapping; Sheet Metal Riveting; Sheet Metal Grinding;When it comes to VIKING AIR TOOLS Air-Powered Sheet Metal Notchers, you can count on Grainger. Supplies and solutions for every industry, plus easy ordering, fast delivery and 24/7 customer support. VIKING AIR TOOLS Air-Powered Sheet Metal Notchers - .Using the Sheet Metal workbench, I'm trying to design a part that looks almost exactly like the picture I've linked at the bottom. The sketch of a U-shape gets turned into a Base Bend and then the cutout is added by Sketch On Sheet. The cutout is too close to a bend, so I know I can expect deformation if I don't work around it.

S. B. Whistler & Sons developed and patented the first reusable Modular Die System for punching and notching and since 1917, has been an industry leader in development of new tooling technologies for sheet metal stamping. Whistler Adjustable, Magna Die 2000 and XimmiX Modular Die Systems incorporate innovative, patented features that meet and .

slotting operation in sheet metal

high manufacturing cost for cnc metal

high precision auto part manufacturers

slitting process in sheet metal

Utility poles can be made of wood, metal, concrete, or composites like fiberglass. They are used for two different types of power lines: sub transmission lines, which carry higher voltage power between substations, and distribution lines, which distribute lower voltage power to customers.

notching in sheet metal|shaving operation in sheet metal