cnc machine spindle torque In physics, power is defined as the amount of energy transferred per unit of time. In the case of CNC machining, the electrical network passes energy to the spindle’s electric motor, which passes it to the cutting tool. The cutting tool uses this energy to extract material from a workpiece. Assuming the efficiency is . See more Have you ever noticed a star adorning the exterior of a house and wondered about its significance? These stars are seldom the same, often seen in various colors, sizes, and materials — they are not just decorative elements; they carry a wealth of history and meaning.

0 · spindle torque range

1 · spindle torque chart

2 · spindle speed and torque

3 · spindle power and torque

4 · spindle motor torque

5 · cnc spindle torque diagram

6 · cnc spindle torque calculator

7 · cnc machine spindle

$27.49

spindle torque range

In physics, power is defined as the amount of energy transferred per unit of time. In the case of CNC machining, the electrical network passes energy to the spindle’s electric motor, which passes it to the cutting tool. The cutting tool uses this energy to extract material from a workpiece. Assuming the efficiency is . See more

In mechanics, the power of a motor is the product of the torque and the shaft’s angular velocity. In machining, this translates to the Torque acting on the spindle multiplied by . See more

By understanding each parameter’s effect on machining power consumption, we can decide what to change when we want to optimize an application for less power consumption. See moreTypical values of KC1 and MC values are shown in the below table. The difference between specific materials within the material groups is not significant and the accuracy is good . See more

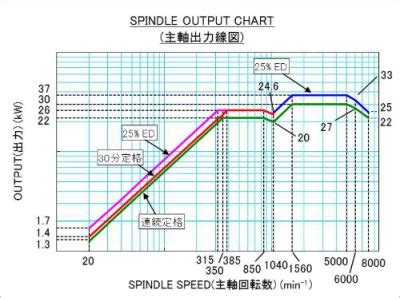

Two fundamental limitations on machining performance are the spindle motor’s available torque and power. The specifications of the torque and power limitations are often available in torque and power curves from machine .This diagram shows how much power and torque are available at various spindle speeds. If you exceed the torque available, the motor will stall, just stop rotating. If you exceed the rated . Torque, not power, is the most important characteristic for determining the cutting performance of a spindle. Increasing spindle torque for a high speed machining center ultimately affects not only the choice of spindle . The right spindle for your CNC machine depends on the specific machining tasks, material types, and the precision required. High-speed spindles are suited for detailed, fine work, while high-torque spindles excel in heavy-duty cutting and milling. CNC machine spindles are the heart of any milling or cutting machine, dictating the quality of .

spindle torque chart

When searching for insights on a ‘cnc machine spindle’, grasp the core role it plays in CNC (Computer Numerical Control) machining. The CNC spindle is the powerhouse that drives the cutting tools, directly impacting the precision, .This machine tool has one Z-axis and one CNC axis; The main shaft and gearbox have been specially optimized. Designed for drilling with high torque and axial force. We can provide various processes such as drilling, boring, expanding, reaming, and internal threading. . Distance between spindle center and column. 480mm. Spindle. Spindle taper . The legs of any CNC machine, spindles are comprised of a motor, a taper for holding tools, and a shaft that will hold all of the components together. . Every machine and spindle should come with a torque horsepower chart. These charts will help you understand how to maximize your spindle for torque or horsepower, depending on what you need:

For example, a 5-axis CNC machine with a 15 HP spindle motor is designed to handle heavy material removal without overloading the motor. However, if the spindle is constantly running at or near maximum load, it can reduce the motor’s lifespan. Monitoring the spindle load ensures that you are not exceeding these limits during operation.Spindles and VFDs End Mills and Cutters . can my ??? oz-in motors be used on your CNC machine. . Therefore, the torque (lbs-in or pounds at one inch) requirements will be: torque = (50 (1/10))/2(pi) or 5 / 6.2831854. We will leave out the efficiency of the screw/nut combination for simplicity. We get a value of about .7958 lbs-in. Now your . However, for cutting at large diameters and low speeds this might be an issue, although torque increase as speed decreases. I'm wondering if I need to have multiple speeds. Thanks, Matt Similar Threads: Torque for Spindle Motor; Need Help!-Lathe Spindle Not holding Torque when cutting!! Spindle has no Torque; Haas TL-1 Lathe torque.

These tests were carried out on an Okuma CROWN V machining center. The spindle torque signal was readily available in the form of voltage values (−3 to 3 V) from the machine. For forward spindle rotation, the minimum torque is associated to 0 V and the maximum torque (198.1 N m) is achieved at 3 V. The experimental setup is shown in Fig. 8 .

For many CNC machines, this is the power that the machine can maintain indefinitely and is represented on the load meter as 100%. Moving up the scale, S2 is a short-time duty rating. This rating implies that the power is required only for a short amount of time in relation to the total cycle time. We are Specialists in CNC Rotary Table, CNC Spindles, and CNC Angular Head Address: Block G-293, Sector - 63, Noida, Uttar Pradesh, India Office: +918448996972 All India: +919560500384 Choosing the right milling spindle for your CNC machine is crucial for optimizing your machining operations. The spindle directly impacts the precision, efficiency, and capabilities of your machine. . detailed work, while low-speed, high-torque spindles are suited for heavy-duty operations. Torque; Torque is the rotational force generated by .

The horsepower at both the spindle and the motor are shown, as well as the spindle torque for a given spindle speed (RPM). The motor horsepower required for the milling operation can then be compared to the horsepower capability of the machine. . Spindle horsepower (hp) ÷: Machine efficiency (%) / 100 / 100 = We have a new machining coming in replacing our haas. The new machine has a 40HP Cat40 Direct Drive 2 Speed 15k Spindle, The haas had a 15k 30hp spindle. After comparing torque charts, the haas looks like in only has about 5-8 ft lbs lower thru the curve than the new machine. To me this seems crazy as honestly the 30hp haas spindle had no balls.

A CNC spindle is the backbone of CNC machines. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for machining tool application. Depending on the application, . ATO 4.5kW Water Cooled Spindle Motor, 24000rpm, 2.38Nm torque,380V AC,for CNC Router Machine(4.5kw) - Amazon.com. Skip to main content.us. . ATO 3.7kW 3 Phase 380V Water Cooled CNC Router Spindle Motor Feature . Spindle motor with superior durability ER20 collet ensures smooth running.

Projects Measuring CNC mill power, speed and torque. 12 Apr 2018 . It is not very stiff, it can't spin tools very fast, and the spindle motor is a paltry 500W (~0.6HP). It's certainly fun, but these shortcomings become major .

spindle speed and torque

Normally the 5 digit display on the spindle amp would have some display after the "pop". "From what I read Makino had two spindles motors available; 45-4500rpm standard and an optional 60-6000rpm." This may only be a change in the pulleys on the motor and spindle and both using the same motor. There will be parameters that differ also. Bill Its power and torque might be limited depending on the motor housing. Belt-Driven Spindle: This machine spindle can rotate up to 15,000 RPMs. Although it is not as quick as an integral motor spindle, it has an external motor that allows it to deliver more power and torque. . CNC machines containing spindles can also be used in woodworking . Titanium alloys and other difficult-to-machine materials are machined using large-torque CNC machine tools, and asymmetric mechanical spindle is employed in its spindle system. The mechanical spindle demonstrates high power and large torque. The asymmetric design makes the spindle structure more compact while reducing assembly requirements. . In the battle of spindle vs router for your CNC machine, the victor really depends on your specific needs. For industrial-grade operations and longevity, a spindle reigns supreme – but for lightweight applications and a friendly learning curve, a router does the trick.. Spindles provide better torque, consistent power, automatic speed control, and a significantly longer .

Additionally, CNC machine tool spindle components should have high dynamic and static rigidity and resistance to thermal deformation. . It ensures that the spindle meets the torque characteristics required at low speeds. The shifting of sliding gears is mostly achieved by hydraulic forks or directly driven by hydraulic cylinders. For torque specifications on balllscrew components refer to Ballscrew - Installation Tools and Torque Specifications. For torque specifications on the main circuit breaker hardware refer to Haas Main CIrcuit Breaker - Torque Specifications. For torque specifications on the double arms refer to the SMTC - Double Arm - Replacement procedure.the spindle to speed etc. Competition calls their motors 20 hp peak but it is really rated for 10 hp continuous. Below are examples of the standard FX spindle motor and the optional high torque spindle motor: Fanuc B12/8000i : S1: 14.7HP(15HP), . Consider aerospace manufacturing, where a VMC machines high-strength alloys. A spindle with high torque capabilities ensures that the machine can handle the demanding cutting forces required for these materials, maintaining precision and tool integrity.

I am trying to work out the speed and torque required for a spindle motor for a small general purpose lathe, and would appreciate some advice on the specifications to help select one, from someone who is more up to speed with machining than me.

Current plan is to hook up a brushless dc motor to a vfd and have a transmission to a spindle for increased torque. . I have never built a cnc machine personally. I was just adding my 2 cents based on personal experience with VFDs and machining. I am a machinist by trade and a hobbyist. I have used VFDs in my shop to run an old lathe and mill .

spindle power and torque

cnc machining bronze part

They are commonly called "barn stars" since they are often seen gracing the fronts of barns. We did some research and here is what we found. In most cases today, homeowners hang the decorative old-looking metal stars on their homes simply because they enjoy and like them. Usually they are 5-pointed and come in various sizes.

cnc machine spindle torque|cnc spindle torque diagram