2d sheet metal drawings In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.

According to a fuse, thinner wire melts quicker at lower amps than thicker wires do IF they are made of the same stuff. For gmaw (mig) I've always used .023. Not cause it's best, but because thats what was in the 1st. mig machine I ever ran.

0 · simple sheet metal drawings

1 · sheet metal layout drawings

2 · sheet metal forming drawing

3 · sheet metal drawing templates

4 · sheet metal drawing symbols

5 · sheet metal drawing standards

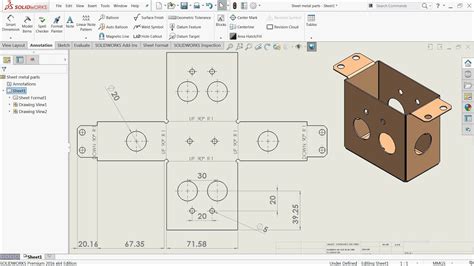

6 · sheet metal drawing in solidworks

7 · metal sheet mechanical drawings

Tagging of the junction box, cables, and cable drums is very important during front-end engineering design for the preparation of the JB schedule, cable schedule, cable drum schedule, etc. In this article, we are going to discuss the .

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, . Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. Sheet metal drawing, a crucial manufacturing process, stands as a cornerstone in the creation of hollow, multifaceted components with a sharp focus on precision. This technique is instrumental in the production of a diverse .

Effortlessly create sheet metal models from 2D sketches, and work directly with geometry. With synchronous technology in Solid Edge, unlike in history-based CAD, features can be edited independently. You can reorder, reorganize, and sort them by name or type.Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Flat pattern drawing views .In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.

Our SolidWorks experts provide precise sheet metal design drafting by converting 2D and 3D CAD drawings into accurate parts for fabricators and manufacturers.Sheet metal parts have unique requirements in the area of 2D drawing creation. In most instances, a drawing view is needed of an unfolded version of the sheet metal part, as well as .

This comprehensive guide aims to educate you on how to read 2D drawings for sheet metal fabrication, paving the way for an efficient and effective fabrication process. Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.

simple sheet metal drawings

Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. Sheet metal drawing, a crucial manufacturing process, stands as a cornerstone in the creation of hollow, multifaceted components with a sharp focus on precision. This technique is instrumental in the production of a diverse range of items we frequently encounter, be it in household goods or specialized industrial equipment. Effortlessly create sheet metal models from 2D sketches, and work directly with geometry. With synchronous technology in Solid Edge, unlike in history-based CAD, features can be edited independently. You can reorder, reorganize, and sort them by name or type.Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Flat pattern drawing views can display bend line notes or bend tables. Search 'Drawings of Sheet Metal Parts' in the SOLIDWORKS Knowledge Base.

In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.Our SolidWorks experts provide precise sheet metal design drafting by converting 2D and 3D CAD drawings into accurate parts for fabricators and manufacturers.

Sheet metal parts have unique requirements in the area of 2D drawing creation. In most instances, a drawing view is needed of an unfolded version of the sheet metal part, as well as a folded version.

This comprehensive guide aims to educate you on how to read 2D drawings for sheet metal fabrication, paving the way for an efficient and effective fabrication process. Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.

Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. Sheet metal drawing, a crucial manufacturing process, stands as a cornerstone in the creation of hollow, multifaceted components with a sharp focus on precision. This technique is instrumental in the production of a diverse range of items we frequently encounter, be it in household goods or specialized industrial equipment.

Effortlessly create sheet metal models from 2D sketches, and work directly with geometry. With synchronous technology in Solid Edge, unlike in history-based CAD, features can be edited independently. You can reorder, reorganize, and sort them by name or type.Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Flat pattern drawing views can display bend line notes or bend tables. Search 'Drawings of Sheet Metal Parts' in the SOLIDWORKS Knowledge Base.

sheet metal layout drawings

In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.Our SolidWorks experts provide precise sheet metal design drafting by converting 2D and 3D CAD drawings into accurate parts for fabricators and manufacturers.

how to determine a subscription box services estimated distribution volume

how to cut expanded metal sheet

While the concept of stamping sheet metal components has traditionally focused on the macro level (e.g. vehicle, aircraft, and packaging applications), the continuing trend of See more

2d sheet metal drawings|sheet metal drawing symbols