cnc part programming codes pdf The examples described in this manual are for learning purposes. Before using them in industrial applications, they must be properly adapted making sure that the safety regulations are fully . The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies.

0 · cnc turning program examples pdf

1 · cnc turning machine programming pdf

2 · cnc turn mill programming pdf

3 · cnc programming pdf free download

4 · cnc programming for beginners pdf

5 · cnc programming codes list pdf

6 · cnc lathe programming example pdf

7 · cnc codes pdf download

Learn essential tips for beginners on how to stick weld thin sheet metal effectively. Discover the right gauge, techniques, and rod choices for successful welding.If you’re dealing with minimal duct tape residue, then you can easily remove it using the scraping off method. The good news is you can eliminate the gunk by using different materials from credit cards to a razor blade and even a set of putty knives. These particular putty knivesare high-quality and have ergonomic . See more

The Programming Manual "Advanced" is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the . Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our .A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .200 Madison Avenue, New York, NY 10016. CONTENTS. Preface. The term numerical control is a widely accepted and commonly used term in the machine tool industry. Numerical control .

The examples described in this manual are for learning purposes. Before using them in industrial applications, they must be properly adapted making sure that the safety regulations are fully . CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. PDF | CNC machines types and simple detailes about G-code language | Find, read and cite all the research you need on ResearchGate . CNC Programming with G-code. July 2022; DOI:10.13140/RG.2.2 .

cnc turning program examples pdf

The Programming Manual "Advanced" is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the SINUMERIK control enables the user to program complex workpiece programs (e.g. for free-form surfaces, channel coordination, .), and makes the programming of complicatedmachine tools in CNC have enabled industry to consistently produce parts to accuracies undreamed of only a few years ago. The same part can be reproduced to the same degree of accuracy any number of times if the CNC program has been properly pre-pared and the computer properly programmed. The operatingM Codes “G” stands for Geometry; hence, the G-Code commands are responsible for the movements of the machine that create the geometry of the part.“M” stands for Machine (or Miscellaneous), and the M-Codes are responsible for Machine commands that cause particular operations of the equipment. Unlike G-codes, which can appear multiple times on the same .

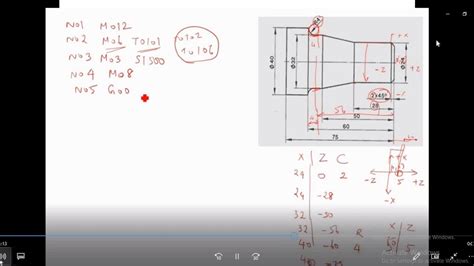

on the tool and material the part is made of. To machin e any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. 1.2 Absolute and incremental coordinates Absolute coordinates (G90): Programming with this type of coordinates implies .functions / M codes M - code is Machine language code to activate miscellaneous functions. M stands for ‘Machine codes’. This code is used for non-geometry machine functions like coolant on/off, spindle speed, tool change, pallet change etc. List of Miscellaneous functions (M codes) Sl no Functions M00 Program stop M01 Optional stop M02 .

metal pencil box for girls

workbook may apply in whole or in part to the programming of other CNC machines. It is intended to give a basic understanding of CNC programming and it’s applications. It is not intended as an in-depth study of all ranges of the machine use, but as an overview of common and potential situations facing CNC programmers. Much more training and Essential G-Code Commands. In CNC programming, essential G-codes streamline complex movements into straightforward instructions. For instance: G00 (Rapid Positioning): Moves the tool quickly to a specific point without cutting, ideal for fast repositioning. G01 (Linear Interpolation): Directs the tool to cut in a straight line at a set feed rate. G02/G03 (Circular .Course Objectives: CLO1 To expose the students to the techniques of CNC programming and cutting tool path generation through CNC simulation software by using G-Codes and M-codes CLO2 To educate the students on the usage of CAM packages and cut part on virtual CNC machine simulator. CLO3 To make the students understand the importance of automation in . CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring for any issues.

The most common codes used when programming NC machines tools are G-codes (preparatory functions), and M codes (miscellaneous functions). Other codes such as F, S, D, and T are used for machine functions such as feed, speed, cutter diameter offset, tool number, etc. G-codes are sometimes called cycle codes because they refer to some action occurring on the X, Y, and/or .component on a CNC system: 1) A part program is written, using G and M codes. This describes the sequence of operations that the machine must perform in order to manufacture the component. This program can be produced off-line, ie, away from the machine, either manually or with the aid of a CAD/CAM system.The document describes developing part programs for CNC turning, milling, and verifying on simulation software. It involves: - Co-developing part programs that control machine tool movement and auxiliary functions to produce a part. - Using codes for functions like linear interpolation, spindle speed, coolant, and tool changes. - Inputting the program into the .

Computer-Assisted Part Programming • In computer-assisted part programming (APT), the machining instructions are written in English-like statements that are subsequently translated by the computer into the low-level machine code that can be interpreted and executed by the machine tool controller. • When using one of the part programming languages, the two main .

Cnc milling programs - Download as a PDF or view online for free. . To prepare a CNC part program to mill the component as per the drawing Assume thickness = 20mm 100 80 40 40 12050 40 50 50 20 20 SIMULATION .Write a G-code program for the part shown below N010 G70 G90 G94 G97 M04 N020 G17 G75 F6.0 S300 T1001 M08 N030 G01 X3.875 Y3.698 N040 G01 X3.875 Y9.125 . •Run CAM software to generate the CNC part program. •Verify and edit program. •Download the part program to the appropriate machine.A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .This manual is a beginners guide to writing macro programs for CNC. It explains the basic functionality of the macro programming language. I will assume you have some knowledge of G-Code programming already, as this is essential before learning the advanced programming techniques provided by the macro language. Section 1. What is macro programming

1. Manual part programming 2. Computer assisted part programming 3. Manual data input 4. NC programming using CAD/CAM 5. Computer automated part programming In manual part programming, the processing instructions are documented on a form called a part program manuscript. The manuscript is a listing of the positions of the tool relative to the work chess pieces program of cnc lathe . - Download as a PDF or view online for free. Submit Search. chess pieces program of cnc lathe . . N105 G01 X20.0 Z-35.0; N106 Z-50 ; G01 X25.0; PART PROGRAM FOR ROOK .

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.Manual Part Programming for Milling (Point to Point Canned Cycles) The component to be machined is shown in Figure 6.7. Prepare a CNC part program to machine the holes on vertical axis CNC machining center using the ISO standard G-codes. You may choose Program Zero (Axes) to be used for the component. Show the axes chosen and write the program.

controlling the part programming, and • description of some common miscellaneous or M codes that are used in most of the CNC machine tools. 4.2 PART PROGRAMMING FUNDAMENTALS As discussed earlier, the numerical control machine tools require a part program to generate the requisite geometric shape of the components. The part program is basically a

Write an efficient CNC part program to drill 35 holes of diameter of 0.5 inch each in a . CNC code. Figure 7.2.1 A component to be machined (drilled) www.getmyuni.com 7. Solution: Based on the G and M code discussed in the last lecture, the CNC part program for FANUC controller can be written as follows: Block 1 % 2 O0001 3 N10 G20 .

Tips for Effective CNC Coding Plan your program carefully: Sketch out your part and plan the toolpaths before writing the code. Use comments: Add comments to your code (using parenthesis; for example (Drilling Operation)) to explain different sections and make it easier to understand later. Simulate your program: Use a CNC simulator to test . CNC Program Codes General The next three chapters contain a description of the CNC program codes and parameters supported by the M-Series Control. The M-Series Control has some G codes and parameters that are modal, and some that are "one shots." The G codes and parameters that are modal will stay in effect until a new G code or parameter is .INTEGRATED MANUFACTURING LAB, code 18MEL76 prescribed by the Visvesvaraya Technological University, Belagavi of this Institute for the academic year 2020 – 2021. MARKS . CLO2: Generate CNC Mill Part programming for Point to point motions, Line motions, Circular interpolation, Contour motion, Pocket milling- circular, rectangular, Mirror .

cnc turning machine programming pdf

metal part fabrication salem

metal outlet box for drywall

According to the 2020 NEC®, our box should have a size of at least eight times the largest conduit when considering straight pulls. Since we're dealing with horizontal straight pulls, we can determine the horizontal .

cnc part programming codes pdf|cnc turn mill programming pdf