roll back sheet metal fabrication 3. Sheet metal, which acts as the workpiece in these processes, is one of the most common forms of raw material stock. The material thickness that classifies a workpiece as sheet metal is not clearly defined. However, sheet . The sheet steel construction and plastic tops make this lightweight cabinet strong and durable. Even though it weighs just 54 pounds empty, each drawer can hold up to 33 pounds of tools. The telescoping handles and oversize wheels make it easy to maneuver up and down flights of stairs.

0 · sheet metal springback calculation

1 · sheet metal bending processes

2 · sheet metal bending machine

3 · sheet metal bending equipment

4 · sheet metal bending design

Claim: Five-pointed stars decorating the exteriors of houses mean the inhabitants are "swingers."

sheet metal springback calculation

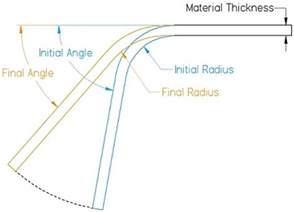

End flare, or end distortion, is unique to roll forming manufacturing, while springback is a more universal sheet metal bending issue. So, what are these two roll forming anomalies? How will they affect your .

Roll Bending. The roll bending process uses 2, 3, or 4 rollers to shape the metal sheet into curves. . This method is used to make cylindrical and conical shapes in sheet metal fabrication, like .

Sheet metal bending has distinct advantages over alternative sheet metal fabrication processes, including higher output, lower cost and high flexibility in design. It also removes many . Sheet roll forming machines have revolutionized metal fabrication by introducing automation and efficiency to the process. These machines bend and shape metal sheets into complex profiles, creating components for various industries, including construction, automotive, and aerospace. Here are the key ways in which sheet roll forming machines enhance metal .

3. Sheet metal, which acts as the workpiece in these processes, is one of the most common forms of raw material stock. The material thickness that classifies a workpiece as sheet metal is not clearly defined. However, sheet .Sheet metal. metal products Free estimates - Call Southeast Fabricating, Inc. (573) 651-6568 - Metal Fabrication Services Company Poplar Bluff MO. (573) 651-6568At Stuart’s, we specialize in delivering high-quality custom sheet metal products tailored to meet your specific needs. Whether you’re looking for bespoke metal roof panels or expertly crafted chimney caps, our team provides precision fabrication and on-site roll forming to . The New Hampshire division of Prototek Rapid Prototyping, Sheet Metal and Machining, a provider of rapid prototyping and one-stop production of precision sheet metal fabrication and CNC machining, has been selected by Meter, a Boston- and San Francisco-based industrial hardware startup, to join a.

sheet metal bending processes

January-February 1971. FMA: The Home for “Fabri-managers” A 12-page newspaper for metal fabricators is published for the first time. The FABRICATOR’s tagline reads: “The Journal Serving Metalworking Industries, With Emphasis on the Processing of Sheet, Plate, and Structurals.”. While the Fabricating Machinery Association, which formed in 1970 as a .What Is Sheet Metal Fabrication? The sheet metal fabrication process takes many steps and requires a team to complete the process. We usually use steel, aluminum, stainless steel, and similar metals for manufacturing, as the industries that use our services need reliable products. Fabricating sheet metal involves stretching, cutting, and bending the metal to create the . Confused by sheet metal processing terminology? Our guide offers a comprehensive list of 71 key terms and definitions to help you navigate the world of sheet metal fabrication with confidence.

EVS Metal is an ISO 9001:2015-certified leader in quality precision sheet metal fabrication with four locations across the U.S. Our stainless steel and aluminum manufacturing capabilities expand far beyond traditional fabrication practices in order to provide clients with a distinct competitive advantage — the option to utilize EVS’ comprehensive range of in-house .Tampa Sheet Metal Company was founded in 1920 by John Jiretz, Sr. John was a skilled craftsman who had learned his trade in Austria and Germany. The custom metal fabrication business has progressed from the early days of using hand tools into a modern facility of custom sheet metal manufacturing equipment including a laser running at the speed of light, robotic . Ever wondered how intricate shapes and precise bends are created in sheet metal? This article dives into the fascinating world of folding machines, revealing their essential role in bending and forming metal sheets. Discover the key principles, structural components, and varied uses of these machines. Learn how they differ from other bending methods and why .

Sheet metal is a great way to express your designs. The material is fairly affordable, and finding a local fabrication shop is just a Google search away. Additionally, with PTC’s Onshape, designing with sheet metal is even easier.The cloud-native CAD and PDM platform is improving the approach to sheet metal design and setting a new standard for streamlined manufacturing .

I think any '3-in-1' tool or machine fits the old adage, "Jack of all trades, master of none." I have a Diacro 52", 16 ga. power shear, a Diacro 52", 14 ga. hand-powered roll, and a Dreis & Krump 8' 12ga, box & pan brake, and I can't imagine trying to .Sheet roll forming machines have become an essential component of the metal fabrication industry, providing significant advantages in efficiency, precision, versatility, and sustainability. Their ability to create complex geometries, reduce material waste, and enhance strength makes them indispensable tools for producing high-quality metal .JET Slip Rolls are a must-have piece of fabrication equipment for any serious fabricator. The store will not work correctly when cookies are disabled. . JET Slip Roll Forming Machines are ideal sheet metal rollers to have in any general fabrication, school, racing, or HVAC shop. Service & .

During a shift, a machine might alternate between manual and robotic operation. Considering all this, Frisk’s team began with what remains the most complicated area in metal fabrication: the press brake department. . Introduction. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This .

We offer three types of Metal Slip Rollers for the fabrication industry. Our metal slip rollers are designed to form sheet metal into cylindrical shapes and bends. They are simple to operate and made of high grade alloy steel and hardened 50 HRC. Another metal slip roller is for our heavy duty Power Bending Rolls, equipped with robust 3.5" rollers designed for customers that bend .This research presents the design and performance test of three roll metal bending machine (shaft design). . A Project Report On DESIGN AND FABRICATION OF SHEET METAL ROLLING MACHINE Submitted By HARSHDEEP SINGH INAYATULLAH FAROOQUI Under the guidance of Prof. ALVI Mr. H. Vishwakarma Submitted as a partial fulfillment of Bachelor of .

Roll forming, sometimes spelled rollforming, is a metal forming process in which sheet metal is progressively shaped through a series of bending operations. The process is performed on a roll .

sheet metal bending machine

Manual CRIMPER BEAD Beader Sheet Metal Roll Roller Former Fabrication 24 Gauge - Rebar Cutters And Benders - Amazon.comPBZ uses advanced metal forming and pressing tools to bend plate and sheet materials to your specifications. We form specific designs by feeding sheet metal through a 235-ton AccurPress Brake with a CNC back gauge. Using several different dies and punches, we work on various metals, such as stainless steel and aluminum.Roll Forming is a continuous bending operation in which sheet metal, coil, strip, or plates are passed through consecutive sets of rolls that gradually shape . Integrated Sheet Metal Fabrication & Assembly of a Complex Coffee Roaster. September 23, 2024; Services14ft 170 ton TruBend 5170 press brake is capable of bending thin & thick complex sheet metal parts with high levels of angular accuracy. Features such as lower tool displacement for hemming and 6 axis backguages provide us a unique advantage and complete production freedom from programming, to set up, to bending productivity the innovated features of this machine allow .

Introduction: The sheet metal fabrication industry is undergoing a profound transformation, driven by technological advancements, sustainability concerns, and changing market demands. This article explores the future of sheet metal fabrication, highlighting key trends and forecasts that are shaping the industry’s evolution. Automation and Robotics Automation .Sheet Metal Fabrication. Laser Cutting; Plasma Cutting; Metal Forming; Metal Rolling; Metal Finishing; Metal Cutting; . 175 Ton and 250 Ton Wysong Press Brakes – 12’ bed with 24” & 48” CNC back gauging. . Trumpf Trubend 7036 Press Brake. 3/8” x 6’ Plate Roll. Sharp Vertical Mill – 2-Axis Digital Readout, Power feed, 1’ x 50 .Top 10 Best Sheet Metal FABRICATION Shop in Los Angeles, CA - November 2024 - Yelp - H Ironworks, Iron Men Gates & Doors, Aero Welding & Manufacturing, Brady Sheet Metal, Edgar's Mobile Welding, JCR Iron Works, Fab-Tech Custom Fabrication & Welding, Ornamental Welding and Repair, Victor's Wrought Iron, Aleman Welding

sheet metal bending equipment

cnc machine tool machine monitoring

Classic Wheatley metal fly box from the early 1900's. "Silmalloy" metal with hinged cover and fly hooks. Swing leaf type with four pages. Holds 161 flies. Marked "Wheatley, Silmalloy Metal" on back. Measures 6 x 4 x 1-1/4 inches thick. This box is in very good original condition with only light scratches from honest use.

roll back sheet metal fabrication|sheet metal springback calculation