cnc machine working operation CNC machining is a subtractive manufacturing process that uses computer-controlled machines to remove material from a solid workpiece to create a desired part. It encompasses a variety of techniques and machine . TICONN Waterproof Electrical Junction Box IP67 ABS Plastic Enclosure with Hinged Cover with Mounting Plate, Wall Brackets, Cable Glands (Clear, 8.7"x6.7"x4.3")

0 · types of cnc operations

1 · different types of cnc machines

2 · cnc machine setup operator

3 · cnc machine operator meaning

4 · cnc machine operations list

5 · cnc machine operation basics

6 · cnc machine operating instructions

7 · cnc machine basic knowledge

$27.14

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages .

This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols. What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3 steps. CNC machining is a subtractive manufacturing process that uses computer-controlled machines to remove material from a solid workpiece to create a desired part. It encompasses a variety of techniques and machine .The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools. This allows factories to produce parts accurately and at a rapid pace, making it .

CNC machine operator are at the heart of manufacturing, responsible for turning ideas into tangible products by setting up, maintaining, and programming CNC machines 1.Their work spans multiple industries, including .Learning G-code can enhance your ability to customize operations and troubleshoot issues. Toolpaths. . Controller: The computer or device that interprets the G-code and sends commands to the CNC machine. WCS (Work Coordinate System): A system used to define the position of the workpiece on the CNC machine. Understanding WCS is essential for .Custom Hoists, Inc. is seeking a skilled and dedicated CNC Machine Operator, skilled in Mill, Lathe, and Cut-off processes, to join our dynamic team. As a Machine Operator, you will be responsible for the efficient operation, maintenance, and monitoring of various machines on our production line. . Ability to flex work assignment as workflow .

#cncmachining In this video, you’re going to learn what CNC machining is and how it works. After watching you will have a good understanding of CNC machining.You must have heard the name “CNC” if you are into manufacturing or engineering stuff. CNC stands for Computer Numerical Control”. CNC Machines are automated control machines that utilize a computer program to move the cutting tool or workpiece to achieve the desired function.. In other words, during CNC machining operation, the cutting tool is moved automatically to . Prioritize safety in CNC machine operation to ensure a secure work environment. Continuously enhance your skills through training and resources to stay competitive. Why CNC Skills are Essential for Career Advancement. CNC skills play a vital role in the manufacturing industry, making them essential for career advancement. As the industry . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

The CNC Machine Operator will work with other team members and report to the Shop Manager. This role is responsible for reading blueprints, checking finished parts, and operating CNC mills and/or lathes. The CNC Machine Operator will: Safely operate a CNC machine to create precision components;A CNC (Computer Numerical Control) Operator is responsible for running CNC machines that cut, shape, and finish metal and other materials. They input instructions into the machine, ensure materials are properly loaded, supervise the cutting process, make adjustments as necessary, and verify the final product meets specifications.

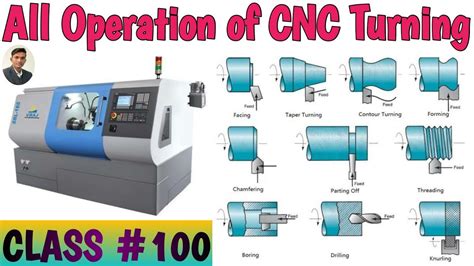

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process.The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method. This means that material gets removed during the production process, . A CNC lathe machine performs operations like facing, turning, parting, drilling, thread cutting, knurling, tapering, chamfering, and boring. Advantages. High accuracy and repeatability for symmetrical shapes. . A CNC router machine works on the same working principle as the CNC mill. The difference is that router machines softer material and .The best CNC Machine Operator Resume Examples with Headline, Objective statement, Description and Skills. Download Sample Resume Templates in PDF, Word formats. . Experienced in working with various CNC machines and technologies, as well as with a range of materials. Highly knowledgeable in reading blueprints and drawings to program and . 1. Power control area. 1. System on: turn on the system power. 2. System off: turn off the system power. 3. Program protection switch: turn on and off the program input function. 4. Emergency stop knob: In case of danger or emergency during processing, the machine tool needs to be stopped in an emergency, or when the power supply of the machine tool is cut off after .

The Machine Operator will ensure the consistent production of a superior concrete masonry unit. Additionally, at the direction of the Plant Manager, the Machine Operator may, from time to time, serve as a team lead to assist and provide guidance to other employees in the completion of their daily tasks in a non-supervisory role.Before you begin operating a CNC machine, it is crucial to take the necessary safety precautions to ensure your well-being and the smooth functioning of the machine. . Keep the work area clean and organized to avoid tripping .A great machine operator is reliable and able to work with attention to detail and safety standards. CNC Machine Operator 3rd Shift. GE Aviation. Wilmington, NC 28429. . The ideal candidate will be responsible for setting up and operating CNC machines to produce precision parts and components according to specifications.

precision machining service manufacturers

CNC Machines. CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed part 1. These computerized machines, called CNC machines, are capable of operating with high precision and .

types of cnc operations

The heart of a CNC Machine Operator’s work lies in accurately interpreting technical drawings and blueprints to produce precise, high-quality components or products. The ability to understand these drawings directly impacts the quality of the final output. Therefore, hiring managers want to ensure you possess the necessary skills to interpret .

Understanding the Mechanics Behind CNC Machining: How Does a CNC Machine Work? CNC (Computer Numerical Control) machining represents a cornerstone of modern manufacturing, offering precision and efficiency in producing parts across various industries. . G-Code is the language that directs CNC machines in their operations. It is a set of . What is a CNC Drilling Machine and How Does It Work? . Several CNC machine drilling operations can include Raised Panel Drill HA, Deep Hole Drilling, Micro Drilling, and spread-the-joy drilling. They can also do spot drilling, counterboring, countersinking, and reaming. Some CNC drilling services include helical drilling to produce larger .What Is a CNC Machine? CNC stands for computer numerical control; it is a process that allows for tool automation. While people may believe that CNC machinery is a small, bespoke set of automated machines, in reality, the CNC designation stretches across many different kinds of computer numerically controlled machine tools.

precision metal manufacturing northglenn co

Here are the top parameters you should know when working with a CNC machine: 1. Spindle Speed (RPM) . you can improve the quality of your work and maintain smooth operations in your machine shop. Whether you’re machining simple components or complex parts, being familiar with these parameters is essential for any CNC operator or machinist. In this video, we take an in-depth look at the working and operating principles of a CNC machine. Our team of experts will provide a step-by-step explanation. Lathe Machines are generally designated with a swing which is the largest working diameter that swings the lathe bed. A Lathe swing is used to rotate objects that can do cutting, sanding and drilling. . The inside and outside of the component may be machined using CNC turning machines. Internal operations will act to change the workpiece’s .Momentum Manufacturing Group is a leading manufacturing partner to OEMs and product manufacturers across a variety of markets. With a skilled workforce of over 800, 13 manufacturing facilities across the Northeast, 750,000 sq. ft. of manufacturing space, and a full suite of in-house metal manufacturing and value-added capabilities, we are an integral and trust supply chain .

CNC Machinists and CNC Operators both work with CNC equipment and often collaborate on jobs. The Machinist focuses on setting up the equipment based on the program designed by a CNC Programmer. When the machine is ready, the CNC Operator takes over and runs the machine. The CNC Machinist also typically handles errors or issues with the program .

different types of cnc machines

This Non Metallic junction box made out of high-quality ABS by Famatel is the perfect solution for indoor and outdoor wiring, installations and connections. This enclosure is resistant to water, dust, and many other elements.

cnc machine working operation|types of cnc operations