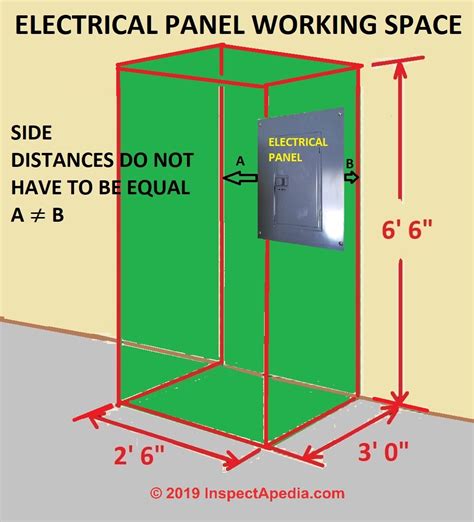

electrical code box clearance [Click to enlarge any image] Summary: clear working space required in front, at sides and above an electrical panel include the following: 1. 6' 6" total height at the electrical panel 2. . See more CNC EDM Wire Cut Machine refers to a wire EDM machine that uses continuous moving fine metal wire as an electrode, on the workpiece pulse spark discharge to remove the metal, cutting and forming. Early CNC wire EDM machines used electric model-tracking to control the cutting path.

0 · osha electrical panel clearance

1 · nec and osha electrical clearance

2 · electrical panel clearance space

3 · electrical panel clearance regulations

4 · electrical panel clearance

5 · electrical clearance requirements

6 · electrical clearance distance chart

7 · building code electrical panel clearance

A double tapped breaker is a circuit breaker that has two circuit wires connected to it. This is a no-no! One circuit breaker should only connect to one circuit.According to the distributive property, multiplying the sum of two or more addends by a number will give the same result as multiplying each addend individually by the number and then adding the products together. To “distribute” means to divide something or give a share or part of . See more

That is to say that "working space" around an electrical panel is synonymous with "clearance distances" around an electrical panel. See more[Click to enlarge any image] Summary: clear working space required in front, at sides and above an electrical panel include the following: 1. 6' 6" total height at the electrical panel 2. . See moreAccess and working space shall be provided and maintained about all electrical equipment to permit ready and safe operation and maintenance of such equipment. See more(A) Accessibility Circuit breakers and switches containing fuses shall be readily accessible and installed so that the center of the grip of the operating handle of the switch or circuit breaker, when in its highest position, is not more than 2.0 m (6 ft 7 in.) above the . See more

The 2021 International Residential Code (IRC) requires electrical panels to have a clear working space to ensure safe operation and maintenance can be provided.

When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the .

Clearance: Electrical panels must be installed in a readily accessible area with a minimum clearance of 30 inches (762 mm) wide, 3 ft (36 inches or 914 mm) deep, and 6.5 feet (≈ 2 .

Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be . An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards .

OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions . Clearance Tables includes working space and clearance around indoor electrical panel, Circuit Board (NES 312.2), clearance for conductor entering

In the United States, the National Electrical Code (NEC) is the primary standard that establishes the minimum clearance requirements for electrical panels. The Occupational Safety and Health Administration (OSHA) .

Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety. Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an .There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.The 2021 International Residential Code (IRC) requires electrical panels to have a clear working space to ensure safe operation and maintenance can be provided.

When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.Clearance: Electrical panels must be installed in a readily accessible area with a minimum clearance of 30 inches (762 mm) wide, 3 ft (36 inches or 914 mm) deep, and 6.5 feet (≈ 2 meter) high in front of the panel.Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees.

An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards such as electrocution, fire, or equipment damage.OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks. Clearance Tables includes working space and clearance around indoor electrical panel, Circuit Board (NES 312.2), clearance for conductor entering In the United States, the National Electrical Code (NEC) is the primary standard that establishes the minimum clearance requirements for electrical panels. The Occupational Safety and Health Administration (OSHA) also has regulations that apply to .

Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety. Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an accident.There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.The 2021 International Residential Code (IRC) requires electrical panels to have a clear working space to ensure safe operation and maintenance can be provided. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.

Clearance: Electrical panels must be installed in a readily accessible area with a minimum clearance of 30 inches (762 mm) wide, 3 ft (36 inches or 914 mm) deep, and 6.5 feet (≈ 2 meter) high in front of the panel.Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees.

An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards such as electrocution, fire, or equipment damage.

OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks. Clearance Tables includes working space and clearance around indoor electrical panel, Circuit Board (NES 312.2), clearance for conductor entering In the United States, the National Electrical Code (NEC) is the primary standard that establishes the minimum clearance requirements for electrical panels. The Occupational Safety and Health Administration (OSHA) also has regulations that apply to .

electric motor conduit box positions

Weatherproof junction boxes, as the name suggests, are designed to withstand exposure to harsh weather conditions. These boxes are typically made of durable materials, .

electrical code box clearance|nec and osha electrical clearance