parts of cnc machining center Key Takeaways: CNC turning centers are essential for precision machining, offering high accuracy and efficiency in producing cylindrical parts. Understanding the components, . Get the best deals on Metal Office Filing Cabinets with 4 Drawers when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

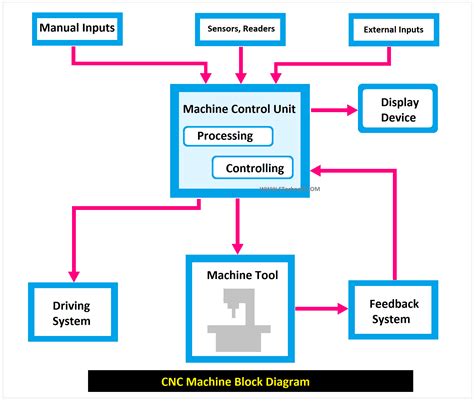

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · main components of cnc machine

3 · cnc machine parts list pdf

4 · cnc machine parts list

5 · cnc machine parts diagram

6 · block diagram of nc machine

7 · block diagram of cnc machine

$269.99

Drilling — A rotating cutting tool cuts holes into a workpiece. Boring — Creating a precise internal cavity in a workpiece by material removal. Broaching — Sequential material removal with shallow cutting strokes. Sawing — Slicing a .

Key Takeaways: CNC turning centers are essential for precision machining, offering high accuracy and efficiency in producing cylindrical parts. Understanding the components, . Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of .

Most machining centers are numerically controlled. A CNC machining center uses computerized numeric control (CNC) to manufacture complex parts in metal or other materials. Typically, a CNC machine center uses a program which conforms to the EIA-274-D standard, commonly called G-code. A drill center automates the drilling of holes in a workpiece.

CNC machining centers have revolutionized the way manufacturers produce intricate parts with speed and accuracy. By understanding the types of machining centers available, their components, applications across various industries, as well as weighing their advantages and disadvantages - one can truly appreciate the impact these advanced .Machining centers are equipped with an _____ that automatically changes and stores the cutting tools. automatic tool changer. A basic CNC milling machine has _____ axes of movement. . which then drives the equipment to machine the parts.This program tells the machine how to move and process parts by reading special codes or instructions. A CNC machining center has a tool magazine that can automatically change tools. This means it can perform many different tasks on a workpiece after clamping it just once. The CNC system controls the machine to select and change tools, adjust .

Study with Quizlet and memorize flashcards containing terms like What part of a CNC system reads and executes the machining instructions in the part program?, What is the purpose of a CNC machining center? Machining centers enable a single machine to:, Which of the following is an advantage of CNC systems? CNC systems: and more. CNC turning center is a type of comprehensive machine combines the technology of computer science, electronics, mechanics and more, . they look similar on the outside and both functioning as the machine for processing turned parts. CNC turning center is also a computer-controlled machine but has higher capabilities. Turning centers are . User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values. . although the design is scalable for larger parts. Each of the three machining centers is served by its own tool changer, with a 12-tool capacity as .

The CNC controller serves as the brain of the machine. It is responsible for controlling the movements and functions of the CNC milling machine. The CNC machining process involves several essential stages: programming the product file, preparing the machinery, and executing machining operations. CNC controllers eliminate the need for manual . CNC machines are the gold standard for high-quality and high-repeatability machining because they automate the machining process — computers and sensors control the machining operations. CNC machining is used in almost every industry due to the quality and precision of the parts it produces, coupled with relatively low labor requirements.Mori Seiki NT4300 DCG1500 is a CNC machining center capable of producing a range of parts across numerous industries. Learn about its specifications, features, and reviews. Rapid . The NT4300-DCG1500 model is part of a series that has been continually updated to incorporate cutting-edge technologies and meet evolving industry demands since . CNC machining centers have become a wild card for manufacturers as many machines do their job alone. It allows you to do the work of a milling machine, a lathe and even a drill machine at the same time. . You can produce prismatic parts in CNC machining centers. It has a great design for you to do profile processing activities.

CNC machining centers are an important part of modern manufacturing, used to manufacture complex parts with high precision and high efficiency. Its main functions are milling, drilling, and tapping, and it is generally applicable to various materials, including steel, aluminum, copper, and other metal materials. . Some parts can be CNC machined using 3-axis CNC machining through multiple setups, but 4 or 5-axis CNC machining can significantly reduce the number of setups and, consequently, setup time. Although the unit time cost of 4-axis and 5-axis CNC machining is higher, if the total machining time is substantially reduced, it becomes more cost .

schematic diagram of cnc machine

3Q Machining provides a variety of precision CNC machining services including milling, turning, EDM (electrical discharge machining) and wire EDM, and surface grinding.With our precision 3-, 4- and 5-axis CNC machining centers, .The Fanuc ROBODRILL AD21MIA5 presents an efficient solution for manufacturers seeking a premium CNC machining center. Known for high precision and speed, this machine serves well in various sectors such as aerospace, automotive, and electronics. It facilitates the production of components ranging from small intricate parts to larger assemblies. The best upgrade for CNC lathe machine parts varies depending on user needs. A range of possible improvements can be considered depending on the quality of the lathe machine parts. . Although lathes are some of the earliest tools for CNC machining, turning centers are upgrades. They take the capability to a higher level, adding automated tool .The CNC 4 axis machining center adds a rotary table to the worktable of the 3 axis machining center, so that one clamping can complete the machining of the four sides of the part. This extra axis allows the machine to rotate the workpiece around one of the main axes (usually the X or Y axis), enabling more complex and intricate machining tasks.

dallas metal fabricators inc

2.How a vertical machining center works. Based on the design model of the parts, the vertical machining center converts the numerous machine tool data generated during the machining process and the machining parameters required for the parts into information codes that are generally accepted and read by the machine tool CNC device. In essence a CNC machining center is a machine tool used for producing parts with features quickly. Its various components collaborate to execute CNC tasks like milling and drilling showcasing machining capabilities due to its standout features.

Choosing the right CNC machine tools is crucial for successful CNC machining operations. These CNC machining tools are of different types, ranging from milling to turning, grinding, and turning tools. Each of these CNC machine tools has its respective properties and uses. However, it is essential to understand the right CNC machine tools for your [.]

data cable junction box

parts made by cnc machine

A machining center is a CNC machine tool that can perform different operations like milling, boring, drilling. Understand everything about them! . Due to their ability to produce complex parts with high accuracy, machining centers are used for manufacturing highly complex parts such as wing frames, impellers, propellers, heat sinks, etc.The machining range of horizontal CNC centers is a crucial factor that determines their suitability for various manufacturing tasks. This section explores the key elements of a horizontal CNC center’s machining range, including the X, Y, and Z axes, rotary axes, and the permissible workpiece size and weight. X, Y, and Z Axes CNC machines: CNC machines are computer-controlled machines that can perform various tasks, such as cutting, drilling, engraving, and 3D printing.They use different tools and methods depending on the material and the desired shape. CNC milling machines: CNC milling machines are used to make metal parts with high precision and accuracy.They have a .

5-axis CNC machining. Multi-axis CNC machining centers come in three variations: 5-axis indexed CNC milling, continuous 5-axis CNC milling and mill-turning centers with live tooling. . With Protolabs Network, outsourcing parts for CNC machining is easy, fast and highly price-competitive. By combining a network of manufacturing services with .

In modern machining centers, CNC technology plays a vital role. It allows operators to program complex tool paths and control the movement of multiple axes simultaneously. This level of automation and precision has significantly enhanced the capabilities of machining centers, enabling them to produce intricate parts with tight tolerances and .The form for machining test parts is included in Chapter 8 as Form 8.1. Document History. ASME B5.54 January 1, 2005 Methods for Performance Evaluation of Computer Numerically Controlled Machining Centers . This Standard establishes requirements and methods for specifying and testing the performance of CNC machining centers. In addition to .

main components of cnc machine

If you're looking for used Folding Machines machines, Machine Hub is the marketplace for you. Get free quotes from our vast network of used machinery dealers.

parts of cnc machining center|block diagram of cnc machine