cnc machine code pdf file Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download. To determine the right drill bit size for a #10 sheet metal screw, you can utilize a simple formula. For #10 screws, the recommended drill bit size is typically 3/16 of an inch. This .

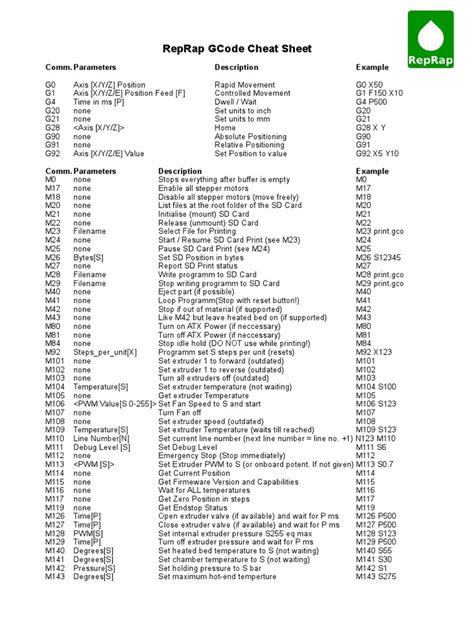

0 · g code cheat sheet PDF

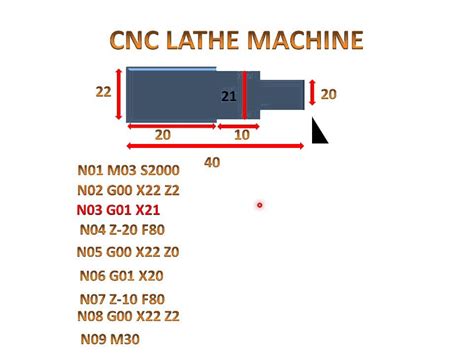

1 · cnc turning machine programming PDF

2 · cnc programming codes list PDF

3 · cnc programming codes PDF download

4 · cnc lathe programming codes PDF

5 · cnc codes list PDF

6 · cnc codes PDF download

7 · cnc PDF free download

Choose the size needle based on the weight of your fabric; a heavier fabric containing only accents of metallic threads will require a size 14 or 16 needle. Lames, which tend to be very fine in weight, need a size 11 needle. Another needle option for these fabrics is a metallic/metafil needle.

So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of . Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.

Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC . Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

Software to generate G - Code from the CAD files. Manual G -Code input in controlling software. Digital Read Out. Displays a number, typically an axis coordinates value. What is a CNC .The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. .

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and

So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training? Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

Software to generate G - Code from the CAD files. Manual G -Code input in controlling software. Digital Read Out. Displays a number, typically an axis coordinates value. What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts.The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparationG Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from mach ine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs?

Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training? Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

Software to generate G - Code from the CAD files. Manual G -Code input in controlling software. Digital Read Out. Displays a number, typically an axis coordinates value. What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts.The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparation

g code cheat sheet PDF

cnc turning machine programming PDF

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from mach ine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.

cnc programming codes list PDF

cnc programming codes PDF download

cnc lathe programming codes PDF

A waterproof junction box, as the name suggests, is a protective enclosure designed to house electrical connections and provide a high level of resistance against water. It is commonly used in outdoor installations, areas with high humidity, or any location where moisture poses a threat to electrical systems.

cnc machine code pdf file|cnc codes PDF download