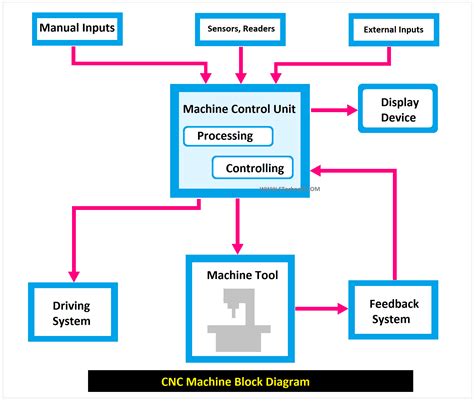

cnc machine component Understanding the key components of a CNC machine is crucial for anyone involved in manufacturing. This article explores the main parts and explains the CNC block diagram. Depends on if you’re hardwiring them or planning to plug them in. If hardwiring, the junction box is built into the appliance. However, code would require that to have a way to disconnect power near the device or a lockout on the breaker. .

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · main parts of cnc machine

3 · diagram of cnc lathe machine

4 · cnc machine tool components

5 · cnc machine parts diagram

6 · cnc machine components list

7 · block diagram of cnc machine

These junction boxes provide a weatherproof outdoor housing for the camera cables and connectors required by security cameras. There is typically eight to twelve inches of camera .

Learn the components of CNC machines online at Industrial Automation Co. CNC machines are made up of a number of parts and .Understanding the key components of a CNC machine is crucial for anyone involved in manufacturing. This article explores the main parts and explains the CNC block diagram.

high quality cnc turned parts

high precision machined parts suppliers

Below, we explore the key CNC components that form the backbone of any CNC machine. For those interested in diving deeper, we’ve provided links to detailed guides on . Understand the parts and functions of CNC machines. From controllers and motors to tool holders and coolant systems, get a detailed explanation of each component to enhance your knowledge. CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two categories: the control system and the . The primary components of a CNC machine are represented by the following: The Input Device. These are the tools used to enter part-programming data into a CNC machine. Three types of input devices are often used: .

high precision milling part manufacturer

CNC machines rely on precise coordination and automation to manufacture parts efficiently. Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials.

This article aims to demystify the core components of a CNC machine, breaking down the intricate interplay of parts that work together to achieve high-precision machining. CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This . With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders. Learn the components of CNC machines online at Industrial Automation Co. CNC machines are made up of a number of parts and components that will need to be maintained, repaired, and replaced over time.

Understanding the key components of a CNC machine is crucial for anyone involved in manufacturing. This article explores the main parts and explains the CNC block diagram.

Below, we explore the key CNC components that form the backbone of any CNC machine. For those interested in diving deeper, we’ve provided links to detailed guides on each component. 1. Machine Bed. The machine bed serves as the foundation of the CNC machine, providing stability and support for all other components.

Understand the parts and functions of CNC machines. From controllers and motors to tool holders and coolant systems, get a detailed explanation of each component to enhance your knowledge. CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two categories: the control system and the machine system.

schematic diagram of cnc machine

parts made by cnc machine

The primary components of a CNC machine are represented by the following: The Input Device. These are the tools used to enter part-programming data into a CNC machine. Three types of input devices are often used: magnetic tape readers, punch tape readers, and computers connected via RS-232-C. Machine Control Unit. The CNC machine’s brain is here. CNC machines rely on precise coordination and automation to manufacture parts efficiently. Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials.

This article aims to demystify the core components of a CNC machine, breaking down the intricate interplay of parts that work together to achieve high-precision machining.

main parts of cnc machine

CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This . With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders. Learn the components of CNC machines online at Industrial Automation Co. CNC machines are made up of a number of parts and components that will need to be maintained, repaired, and replaced over time.

Understanding the key components of a CNC machine is crucial for anyone involved in manufacturing. This article explores the main parts and explains the CNC block diagram.

Below, we explore the key CNC components that form the backbone of any CNC machine. For those interested in diving deeper, we’ve provided links to detailed guides on each component. 1. Machine Bed. The machine bed serves as the foundation of the CNC machine, providing stability and support for all other components. Understand the parts and functions of CNC machines. From controllers and motors to tool holders and coolant systems, get a detailed explanation of each component to enhance your knowledge.

CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two categories: the control system and the machine system. The primary components of a CNC machine are represented by the following: The Input Device. These are the tools used to enter part-programming data into a CNC machine. Three types of input devices are often used: magnetic tape readers, punch tape readers, and computers connected via RS-232-C. Machine Control Unit. The CNC machine’s brain is here. CNC machines rely on precise coordination and automation to manufacture parts efficiently. Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials.

high precision cnc turning part manufacturer

high precision machined parts inspection austin

Sheet metal hem radius, there is only one 180-degree bend in a hem. Some hems are closed, which means that the inside bend radius is zero. The hem’s cross-section resembles a U if its radius is bigger than zero. The hem has one curve rather than .

cnc machine component|schematic diagram of cnc machine