how to bend long pieces of sheet metal It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

Two spacious file drawers open on smooth full-extension ball bearing slides for an effortless reach to all your letter, legal, and A4-size paperwork. Each drawer can support up to 60 pounds of .

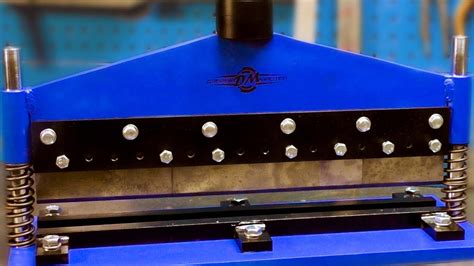

0 · sheet metal bending dies

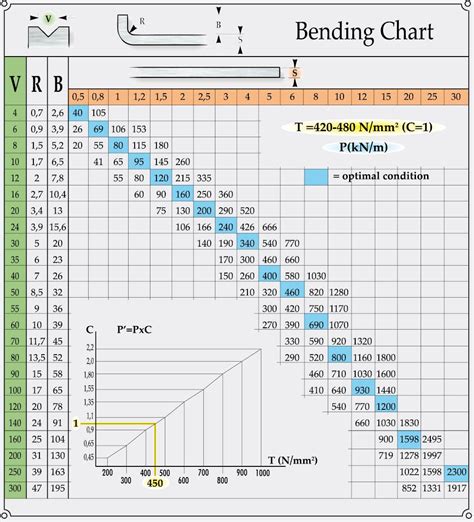

1 · sheet metal bending chart

2 · sheet metal bending by hand

3 · how to bend metal professionally

4 · folding sheet metal at home

5 · bending operation in sheet metal

6 · bending 16 gauge sheet metal

7 · bend sheet metal without brake

Custom and Retail game covers, inserts, and scans for Twisted Metal for Playstation 3

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more

How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools. .more.

sheet metal bending dies

sheet metal bending chart

Improvising a metal brake using some clamped together 2x4s. Key to a straight bend is a sort of "shoe" to whack with a rubber mallet to spread out the force. Simple sheet metal bender using a hand roller, clamps and plywood.Music: Monkeys Spinning Monkeys by Kevin Macleod. A: Some practices that can help prevent cracks from appearing as you bend the sheet metal are: 1. Provide an inside bend radius that is at a minimum equal to the thickness .It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

Guys, this is a simple one. Of course use the pallet that the metal roofing company ships the roofing with. We reinforced the front of the pallet with 10' 2x. Simple sheet metal bender using a hand roller, clamps and plywood.Music: Monkeys Spinning Monkeys by Kevin Macleod Plywood sheet-metal brake. Issue 200. Here’s a simple method for bending a long piece of flashing on a job site. It works with thin-gauge galvanized steel and copper, but for best results, I recommend aluminum coil stock. As . This doesn’t just work with thin sheet metal. You can use this method to bend material that would make a sheet metal bending brake cry. So what is this 2-step diy bending process that can do the job of a press brake? Here’s the secret: Step 1 – Make relief cuts in your part along the line you want to bend. Step 2 – Bend. That’s it, no .

Most hand seamers / sheet metal tongs only have a jaw depth of about 1.25 to 1.5 inches. If you go this route, you can use 2 thicker pieces of metal to sandwich the piece you want to bend for the added depth. Most sheet metal shops would do the bend for you for a buck or two. That is the way I would go. What type material is it that you are .Master the art of bending sheet metal with Shengen, a B2B sheet metal parts manufacturer. Learn basics, advanced techniques, and safety tips. Capabilities. . Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill . In this how to I give an easy example using simple shop tools and materials to bend some thin aluminum sheet without the added expense of an expensive metal .

With the show side up, make about a 30-degree bend. Rotate the piece show side down and bend another 30-degree angle. Flip the piece again and bend it back 30 degrees, or so the face of the fascia is straight. (I know 30 degrees x 3 doesn’t equal 180 degrees, but the point of reference changes with every bend.) In this video, I show you and tell you how to bend sheet metal without a brake. If you have a piece of sheet metal that you need to bend on a ninety degree a.This is not the real world. It's maths pretending to be real things. You use a plane, extrude an edge and then bevel the corner to get the curve you would expect from a sheet metal bender. Lob a solidify modifier on top and hey presto - Stop thinking about how you would make this from sheet metal, it's an utterly different process.

When sheet metal needs to be folded, bent, or curved in a precise manner, a Press Brake is used to make the bend. Using hydraulic pressure, a press point is pushed against metal forming a bend or “Brake” in the metal surface. The brake can be formed at a single point or as a complete fold in the sheet metal piece. Brake Time The type of metal flashing you are using, will determine the exact process for bending the metal. Much aluminum flashing can easily be bent by hand. However, 40 ounce of copper flashing is the best when it is bent with a machine. If you are roofing a large area, you will want to use a sheet metal brake.Method 2 is just to cut a curved piece out of a plate with the right radius and bend a piece of bar to match it so you're sort of fabricating a piece of angle. Bonus points for cutting one leg off the end of the angle iron and replacing it with the curved chunk you cut out of plate then bend the remaining leg to fit it. You can make a jig to serve as a bench (bending) brake, if you have some heavy-duty C-clamps. You need to cut some strips of lumber as long as the metal strip, and clamp them tightly to the sheet along both sides of the bend location. Bevel the edges about 50 deg on the side you are bending toward. Here is a sketch to start you off:

sheet metal bending by hand

This tip from the Video Vault, courtesy of David Kalin of Kaneohe, Hawaii, and demonstrated by Chuck Miller, is a simple method for bending steel, copper, or aluminum flashing on site. As Chuck points out, the flashing can .Once you’ve scored the metal, you can simply bend the metal up along the scored line to make your bend. So long as you have the pieces clamped good, the bend should be pretty easy. If you need a tight edge, you can use a .Add a double bend to a sheet metal face. On the ribbon, click Sheet Metal tab Create panel Bend. Select a model edge on each sheet metal face. Enter a Bend Radius if it is different from the default for the part. Click the down arrow to .Does bending copper sheet present challenges in the metal fabrication process? Mastering the art and science of bending copper sheets leads to unique and . Long-Sleeved Shirts: Shields skin from metal shards, sparks, and potential heat exposure. . It’s also important to consider the end use of the piece when selecting the bending method .

Discover expert techniques for how to bend corrugated metal roofing with our guide, ensuring your DIY projects are shaped perfectly and safely. . If you are working with large pieces of metal or need to create more intricate bends, a lathe such as a CNC lathe can be a valuable tool. . Position them strategically on the metal roofing sheet .Hi there, I need some advice on making bends in a piece of 304 stainless sheet steel, it's 1.5mm thick and 220mm long, the bends are 20° each along the length. I don't have a machine or press for bending it, is using something flat with a hammer over the .

A long piece of galvanized sheet metal with width w is to be bent into a symmetric form with three straight sides to make a rain gutter. A cross-section is shown in the figure. (a) Determine the dimensions that allow the maximum possible flow; that is, find the dimen- 3. sions that give the maximum possible cross-sectional area.

Learn how to use a straight handle hand seamer to bend sheet metal.Learn about--Sheet metal gauges-Types of hand seamersSign up for the email list. Grab some.You can also bend the aluminum in the “t” condition when the metal is heat-treated. This makes the aluminum more durable and less likely to warp. There are various ways you can bend your aluminum: Use a sheet metal brake. This tool allows you to bend the metal by clamping it down and then using a lever to bend it to the desired angle. Use a . A short video showing how to bend an outside corner demonstrated on a Pro Series metal bending machine but applicable to most machines.www.tapco-europe-tools. I am trying to make a part that is an arced piece of sheet metal with holes on the edges and down the middle (see picture attached), and I want to make it as a sheet metal part so I can get the flat pattern of it. I think there is some way to work with just a flat plat, make all of the holes needed, and then bend it, but my coworker and I can't figure out how to.

That is partially right. Basically imagine a .25" thick sheet of metal with a 90 degree horizontal bend line at the top to create a 2" flange across the whole thing. Then on that same sheet metal, a vertical bend line at center of sheet, which will bend it in/angle it 30 degrees inward. I will try to add a picture also In sheet metal forming, the bending moment determines the stress distribution across the sheet and the material’s behavior under load. When applied to sheet metal, the bending moment increases with the length of the bend. The longer the bend, the greater the force required to bend the sheet metal, resulting in higher tonnages.

how to bend metal professionally

folding sheet metal at home

bending operation in sheet metal

bending 16 gauge sheet metal

Precast underground pull boxes and handholes protect and provide easy access to buried electrical power lines. Environmentally friendly, convenient, and naturally fire resistant, they are ideal for projects that require cabling junction access.

how to bend long pieces of sheet metal|sheet metal bending dies