decorative metal joints for building small wood boxes Gary Rogowski explains techniques for making strong corner joints and matching long grain for elegant but simple mitered boxes. Detailed instructions for . aluminum seat bracket system Mohawk uses aluminum panels which are riveted between the gunwale and the side of the canoe. This means that the stress is spread over the hull rather than a few points on the gunwale.

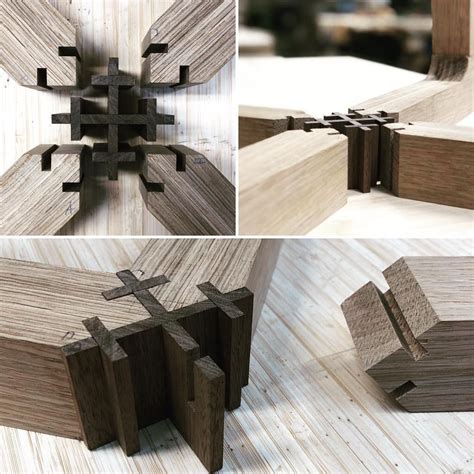

0 · woodworking interlocking joints

1 · woodworking box joints

2 · wood box corner joints

3 · types of wood corner joints

4 · different joints for joining wood

5 · decorative box joints

6 · best corner joint for wood

7 · basic woodworking joints

Il tuo shop online per la vendita di frese e fresette per legno manuali e CNC per la fresatura verticale; scopri i migliori prezzi per la migliore qualità!

Learn how to make three decorative joints when making boxes. Box Joint (also called a finger joint), Splined Miter Joint and Sliding Dovetail Joint will be .Gary Rogowski explains techniques for making strong corner joints and matching long grain for elegant but simple mitered boxes. Detailed instructions for . But the beautiful and straightforward box joint can satisfy on multiple levels: making the jig is both doable and affordable, and the finished joint looks great in so many different applications. It’s no wonder they’ve always been a . Learn how to make a box joint, often called a finger joint. WOOD magazine's Bob Hunter shows you how to make a jig for your tablesaw to cut perfect-fitting box joints. Use this technique on small box construction, drawer construction, even decorative joinery for furniture .

Learn how to make three decorative joints when making boxes. Box Joint (also called a finger joint), Splined Miter Joint and Sliding Dovetail Joint will be .Gary Rogowski explains techniques for making strong corner joints and matching long grain for elegant but simple mitered boxes. Detailed instructions for cutting, gluing, adding biscuits or through-splines, and clamping are given, along with cutting and fitting keyed miters, dovetailed miters, and veneer splines.

Choosing Wood Types: Consider grains & patterns for plans for wooden boxes. Joinery Techniques: Build a sturdy simple box with quality wood glue. Finishing Touches: Painting, and decorating the perfect wood jewelry box. Maintenance and Care: Protect your box from wear and potential damage.Although not an exhaustive list of joints, you will find that the vast majority of wooden boxes employ one of these types to secure their corners. 1. Dovetail. A hallmark of craftsmanship and strength, the dovetail joint can be cut by hand, machine or a combination of both. That is why we have put together a list of these 42 great DIY wooden box plans to keep something your necessary and precious. 1. Basic Wooden Boxes. 2. DIY Few Simple Boxes – Instructables. 3. DIY Wooden Jewelry Box. 4. DIY Wooden Box Centerpiece. 5. DIY Wooden Crate. 6. DIY Wooden Toy Bin. 7. DIY Vegetable Storage Box. 8. But the beautiful and straightforward box joint can satisfy on multiple levels: making the jig is both doable and affordable, and the finished joint looks great in so many different applications. It’s no wonder they’ve always been a popular choice for .

Learn how to make a box joint, often called a finger joint. WOOD magazine's Bob Hunter shows you how to make a jig for your tablesaw to cut perfect-fitting box joints. Use this technique on small box construction, drawer construction, even . If you’re looking for a versatile joint that adds a decorative touch to your woodworking projects, look no further than the box joint. I’ll break down everything you need to know, including what they are, whether they’re strong, some practical applications for them, and how to make them using three different tools.Metal corners can help prevent the wooden box from cracking or breaking, making it a great option for storing valuable or fragile items. Additionally, metal corners can be made to fit snugly into the wooden corners, creating a seamless and cohesive design. Strong, practical, decorative, and easy to make. What more can you ask of a wood joint? You can't make a box joint if you don't have a box-joint jig. Fortunately, it's easy to make one, following these simple plans. After you build the jig, follow these steps and see firsthand how easily you can master this joinery method.

Learn how to make three decorative joints when making boxes. Box Joint (also called a finger joint), Splined Miter Joint and Sliding Dovetail Joint will be .

woodworking interlocking joints

woodworking box joints

Gary Rogowski explains techniques for making strong corner joints and matching long grain for elegant but simple mitered boxes. Detailed instructions for cutting, gluing, adding biscuits or through-splines, and clamping are given, along with cutting and fitting keyed miters, dovetailed miters, and veneer splines. Choosing Wood Types: Consider grains & patterns for plans for wooden boxes. Joinery Techniques: Build a sturdy simple box with quality wood glue. Finishing Touches: Painting, and decorating the perfect wood jewelry box. Maintenance and Care: Protect your box from wear and potential damage.

Although not an exhaustive list of joints, you will find that the vast majority of wooden boxes employ one of these types to secure their corners. 1. Dovetail. A hallmark of craftsmanship and strength, the dovetail joint can be cut by hand, machine or a combination of both.

That is why we have put together a list of these 42 great DIY wooden box plans to keep something your necessary and precious. 1. Basic Wooden Boxes. 2. DIY Few Simple Boxes – Instructables. 3. DIY Wooden Jewelry Box. 4. DIY Wooden Box Centerpiece. 5. DIY Wooden Crate. 6. DIY Wooden Toy Bin. 7. DIY Vegetable Storage Box. 8. But the beautiful and straightforward box joint can satisfy on multiple levels: making the jig is both doable and affordable, and the finished joint looks great in so many different applications. It’s no wonder they’ve always been a popular choice for . Learn how to make a box joint, often called a finger joint. WOOD magazine's Bob Hunter shows you how to make a jig for your tablesaw to cut perfect-fitting box joints. Use this technique on small box construction, drawer construction, even .

If you’re looking for a versatile joint that adds a decorative touch to your woodworking projects, look no further than the box joint. I’ll break down everything you need to know, including what they are, whether they’re strong, some practical applications for them, and how to make them using three different tools.Metal corners can help prevent the wooden box from cracking or breaking, making it a great option for storing valuable or fragile items. Additionally, metal corners can be made to fit snugly into the wooden corners, creating a seamless and cohesive design.

wood box corner joints

metal fabrication shop seattle

A standard plank is flat and will not have any flexibility, while sprung planks are curved and have more give to them for movement. Standard planks are best for sleepers who want more firmness, and spring is good for those who like softer support.

decorative metal joints for building small wood boxes|woodworking interlocking joints