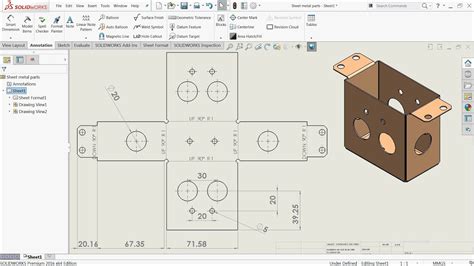

solidworks sheet metal forming Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes . Manufacture of other fabricated metal products; metalworking service activities, General contractors

0 · solidworks sheet metal forming tool

1 · solidworks sheet metal examples

2 · solidworks sheet metal add in

3 · solidworks forming tool library download

4 · solidworks forming tool library

5 · solidworks forming tool

6 · solidworks form tool tutorial

7 · forming tool design

The “Basic Theory of Driving” handbook is essential reading for all road users in Singapore, which comprise the pedestrians, cyclists, motorcyclists and drivers. It covers The Highway Code, which includes the traffic rules, traffic regulations, traffic signs and signals, and it aims to educate and promote road safety for the road users.

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes .Sheet metal parts display the Sheet-Metal feature in the FeatureManager design .

Opening the Model and Inserting a Forming Tool. Next, you open a sheet metal part .In this tutorial, you learn the following: Add a formed louver part to the design .The 3D EXPERIENCE WORKS ® Simulation portfolio includes the ability .Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The .

Opening the Model and Inserting a Forming Tool. Next, you open a sheet metal part and add the formed louver from the Design Library. Browse to the location where you placed the formtools .

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes .

This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a . in this tutorial video i will show you how to use forming tool in sheet metal ..& i hope you will enjoy the tutorial, please subscribe our channel for more . 👉 https://amzn.to/3M85SVuIn this SolidWorks Sheet Metal Tutorial, learn how to effectively use forming tools to create complex sheet metal parts. This tutorial provides a step .

In this tutorial, you learn the following: Add a formed louver part to the design library. Add a formed louver to a sheet metal part. Select a configuration for the formed louver. Replace the . The 3D EXPERIENCE WORKS ® Simulation portfolio includes the ability to simulate the metal-forming process. The products can be leveraged on SOLIDWORKS® models when connected to the 3D EXPERIENCE platform. .

You can use the Stamp tool to create sketch-based parametric forming tools to apply to sheet metal parts. With sketch-based forming tools, you can create a sketch with a few parameters to stamp or form the sheet metal. Normal Cut in Tab and Slot. When you use the Tab and Slot tool, you can specify that the slot is normal to the sheet even if .

Figure 1: Forming a flap into a sheet metal part. Validate on the Fly. Forming simulation tools on the 3DEXPERIENCE platform recreate manufacturing processes virtually to check for potential problems such as . how to use sheet metal module in solidworksIf you don’t know demands I use in this video, please watch my playlist: SolidWorks Tutorial to know more informat.

Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .Open a sheet metal part, and browse to the forming tools folder in the Design Library.; Right-click the folder and click Forming Tools Folder.If Forming Tools Folder is already selected, omit this step. When asked if you want all subfolders to be marked as forming tools folders, click Yes.

https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinYou Can Support our Channel for more tutorials.we will learn sketch,sheet .Modifying the Extruded Hole Forming Tool. Next, you modify the extruded hole forming tool. Testing the Link to Forming Tools. Next, you test the link to the Design Library forming tool part by seeing that the change propagates to the sheet metal part. .

solidworks sheet metal forming tool

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part . we will learn Base flange, Extruded cut, unfold, Fold, Corner break, Solidworks design library, forming tool, bridge lances and Appearance in Solidworks shee.When you insert the forming tool in a sheet metal part, the placement sketch is where you can dimension the forming tool in relation to existing geometry. No base is required to create forming tools. Click Forming . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .If the forming tool has radii that are pushed into the sheet metal body, then the forming tool will fail when the concave radius is smaller than the material thickness. In this case the radius that gets pushed into the sheet metal body becomes negative and forces the tool to fail. . SOLIDWORKS welcomes your feedback concerning the .

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part .Forming tools are a great way to add specific geometry to a sheet metal design. This can range from louvers to lances, to dimples, but forming tools can also help add text or logos to a sheet metal design. This article will help you create custom forming tools in SOLIDWORKS and apply them to a sheet metal model. Geometry CreationYou can create forming tool parts for use in sheet metal parts. Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. Form Tool Feature PropertyManagerYou can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. .

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part files (*.SLDPRT), not Form Tool (*.SLDFTP) files. SOLIDWORKS - Sheet Metal Forming Tool SOLIDWORKS - Sheet Metal Forming Tool / Loading . SOLIDWORKS - Forming Tool.jpg. jpg. March 28th, 2021 SOLIDWORKS - Forming Tool (Done).SLDPRT. sldprt. .2) Best Approach To Modeling Sheet Metal Bodies SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of geometries, the user has the option to use non-sheet metal feature tools and then use the

large ammo box steel

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part files (*.SLDPRT), not Form Tool (*.SLDFTP) files.For Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. See everything new in SOLIDWORKS 2025 Sheet Metal here. SOLIDWORKS. 3D CAD . need to do nothing to experience all the increased performance and drawings of sheet metal parts with many holes and forming tools and working with sheet metal parts with many .When you insert the forming tool in a sheet metal part, the placement sketch is where you can dimension the forming tool in relation to existing geometry. No base is required to create forming tools. Click Forming . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part .Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .Navigate to the forming tools folder. Right-click the folder and click Forming Tools Folder. If Forming Tools Folder is already selected, you can skip the last step. If you are prompted to mark all subfolders to be marked as forming tools folders, click Yes. Close the sample_louver part.Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .

I am trying to perform a bending in a spheric shape on a curved surface using a forming tool which I included in library. When i drag and drop the forming tool from library to the surface which Solidworks seems to tell me this is not possible. Is there any alternative to bent a sheet metal with spheric forming tool?PROFIL is roll form design software for manufacturers of custom roll formed shapes or seamed tubes from sheet metal and designers of roll formers and tube forming machines. With the look and feel of a CAD system, it is easy to use software, Windows compatible, and has a direct SOLIDWORKS interface.

laguna cnc machine for sale

Here to help, particularly with box junctions! In my opinion, the turning right exemption should apply here, based on how the rule is drafted.

solidworks sheet metal forming|solidworks form tool tutorial