deep drawing sheet metal ductile metals. In general, any metal that can be cold rolled into sheet should have sufficient ductility to be deep drawn, but material properties like work hardening or anisotropy .

Our welding technicians work closely with our machinists to customize and finish your parts exactly to your specifications. Call 936-205-9087 or come by Turner Fabrication for your custom quote on welding and fabrication services.

0 · sheet metal deep drawing calculations

1 · products made by deep drawing

2 · metal spinning vs deep drawing

3 · deep drawing vs stamping

4 · deep drawing process step by

5 · deep drawing calculation

6 · deep draw sheet metal forming

7 · deep draw blank size calculation

From CNC motorcycle parts to controls, body protection, engine accessories, and more, we offer everything you need to enhance your motorcycle's functionality and aesthetics. Get an Instant Quote!

Learn about deep drawing, a sheet metal forming technique that creates hollow, elongated shapes with high structural integrity. Explore the factors, advantages, limitations, and innovations of deep drawing and its .Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies.Learn what sheet metal deep drawing is, how it works, and its benefits and limitations. Find out how to calculate size, reduction ratio, and force for deep dra. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels .

sheet metal deep drawing calculations

products made by deep drawing

Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In . ductile metals. In general, any metal that can be cold rolled into sheet should have sufficient ductility to be deep drawn, but material properties like work hardening or anisotropy .

Learn how to perform deep drawing operation for manufacturing defect-free components for various industries. The chapter covers the equipment, steps, analysis, and .

Deep drawing reshapes flat metal sheets into hollow, three-dimensional forms. This process stretches the material over a die, creating complex shapes without seams or joints. Steps .

A deep drawing is a manufacturing technique that transforms a metal sheet into a three-dimensional form through mechanical action. Usually executed using a punch, die, and other tools, this method is perfect for hollow, axisymmetrical .Deep drawing, a key fabrication technique that involves stretching metal sheets into desired shapes with a die and punch mechanism, is fundamental for creating high-quality, uniform, and .Deep drawing is one of the most widely used processes in sheet metal forming. Apart from its use in many other sectors, it is applied in the automotive industry for the manufacturing of car body parts.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.

What is deep drawing in sheet metal fabrication? Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. The depth of the drawn parts often exceeds their diameter. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] It is thus a shape transformation process with material retention.

Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In this article, we’ll dive into the intricacies of deep drawing, .Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. Imagine it as a more specialized version of metal stamping. To execute this technique, position a shaped metal blank over a cavity.Deep drawing reshapes flat metal sheets into hollow, three-dimensional forms. This process stretches the material over a die, creating complex shapes without seams or joints. Steps Involved in Deep Drawing Stainless Steel. The deep drawing process follows a series of .

metal spinning vs deep drawing

Deep drawing is a sheet-metal forming process for manufacturing a seamless hollow part that is closed at one end and has a height (or depth) greater than its radius. Deep drawing involves drawing a sheet metal (blank) into a die cavity; the sheet thickness remains almost the same from start to finish during deep drawing.

What is Deep Drawing in Sheet Metal? Deep Drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. We can consider a component as the deep-drawn if the depth of the drawn part is greater than or equal to the part radius. Deep Drawing Example. Deep drawing of sheet metal is a highly specialized manufacturing process that transforms flat metal sheets into complex, three-dimensional shapes through the application of force and pressure. This intricate technique embodies precision, versatility, and efficiency, making it a cornerstone of modern metalworking.

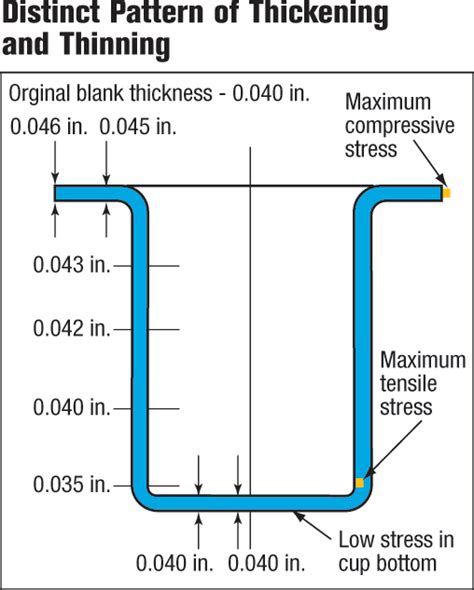

To illustrate the principles of metal flow, this article examines two basic draw shapes, round and square.

Drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry.Deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw the metal into the desired shape without causing wrinkles or splits in the drawn part (Demeri, 2006).Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius.At its core, deep drawn metal stamping is a method used to shape metal sheets into complex geometries. The deep draw stamping process involves applying pressure to a flat sheet of ductile metal, forcing it into a die cavity to create a three-dimensional object.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.Deep drawing, a key fabrication technique that involves stretching metal sheets into desired shapes with a die and punch mechanism, is fundamental for creating high-quality, uniform, and detailed metal parts.Custom Deep Draw Stamping Solutions. Custom Deep Draw Stamping enables the creation of high aspect ratio components from flat metal sheets. This technique minimizes residual stresses, resulting in stronger parts. Precision tooling ensures tight tolerances for seamless assembly. Progressive die design enhances efficiency and allows intricate . In its most basic form, deep drawing uses a punch to force a sheet metal blank into a die cavity to produce a tall, smooth, closed-ended part with the same sheet thickness as the blank. To encourage metal to flow, the lead-in of the die .

The deep drawn stamping process is an efficient metal-forming method that creates complex shapes efficiently and precisely. This process involves drawing a blank metal sheet into a forming tool and transforming it into intricate designs. This method produces high-quality components at lower costs, particularly for large production runs. Welcome to our in-depth tutorial on Deep Drawing Operations in Sheet Metal! In this comprehensive video, we'll delve into the intricacies of this critical process in metalworking. From the. In incremental sheet forming (ISF) strains can be obtained well above the forming limit curve (FLC) that is applicable to common sheet forming operations like deep drawing and stretching.Deep drawing is one of the most widely used processes in sheet metal forming. Apart from its use in many other sectors, it is applied in the automotive industry for the manufacturing of car body parts.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few. What is deep drawing in sheet metal fabrication? Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. The depth of the drawn parts often exceeds their diameter.

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] It is thus a shape transformation process with material retention.

Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In this article, we’ll dive into the intricacies of deep drawing, .Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. Imagine it as a more specialized version of metal stamping. To execute this technique, position a shaped metal blank over a cavity.Deep drawing reshapes flat metal sheets into hollow, three-dimensional forms. This process stretches the material over a die, creating complex shapes without seams or joints. Steps Involved in Deep Drawing Stainless Steel. The deep drawing process follows a series of . Deep drawing is a sheet-metal forming process for manufacturing a seamless hollow part that is closed at one end and has a height (or depth) greater than its radius. Deep drawing involves drawing a sheet metal (blank) into a die cavity; the sheet thickness remains almost the same from start to finish during deep drawing.

What is Deep Drawing in Sheet Metal? Deep Drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. We can consider a component as the deep-drawn if the depth of the drawn part is greater than or equal to the part radius. Deep Drawing Example. Deep drawing of sheet metal is a highly specialized manufacturing process that transforms flat metal sheets into complex, three-dimensional shapes through the application of force and pressure. This intricate technique embodies precision, versatility, and efficiency, making it a cornerstone of modern metalworking. To illustrate the principles of metal flow, this article examines two basic draw shapes, round and square. Drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry.

Deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw the metal into the desired shape without causing wrinkles or splits in the drawn part (Demeri, 2006).

Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius.At its core, deep drawn metal stamping is a method used to shape metal sheets into complex geometries. The deep draw stamping process involves applying pressure to a flat sheet of ductile metal, forcing it into a die cavity to create a three-dimensional object.Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.Deep drawing, a key fabrication technique that involves stretching metal sheets into desired shapes with a die and punch mechanism, is fundamental for creating high-quality, uniform, and detailed metal parts.

Custom Deep Draw Stamping Solutions. Custom Deep Draw Stamping enables the creation of high aspect ratio components from flat metal sheets. This technique minimizes residual stresses, resulting in stronger parts. Precision tooling ensures tight tolerances for seamless assembly. Progressive die design enhances efficiency and allows intricate . In its most basic form, deep drawing uses a punch to force a sheet metal blank into a die cavity to produce a tall, smooth, closed-ended part with the same sheet thickness as the blank. To encourage metal to flow, the lead-in of the die .The deep drawn stamping process is an efficient metal-forming method that creates complex shapes efficiently and precisely. This process involves drawing a blank metal sheet into a forming tool and transforming it into intricate designs. This method produces high-quality components at lower costs, particularly for large production runs.

Welcome to our in-depth tutorial on Deep Drawing Operations in Sheet Metal! In this comprehensive video, we'll delve into the intricacies of this critical process in metalworking. From the.

If you have a large quantity of relatively small metal parts that need finishing, Fotofab offers tumbling and deburring to finish your parts with high-quality precision. This method is used to deburr, radius, burnish, descale, clean, polish, and brighten metal component surfaces.

deep drawing sheet metal|deep draw blank size calculation