build a metal cutting cnc machine I decided to put my engineering background to the test, and build my own CNC . A Septic Tank Distribution Box, also known as a D-box, is a junction box positioned between the septic tank and the drain field (or leach field). Its primary function is to evenly distribute the effluent (wastewater) from the septic tank into the various distribution lines within the drain field.

0 · industrial metal laser cutting machine

1 · hobby cnc machine for metal

2 · cnc metal cutting machine price

3 · cnc laser cutter near me

4 · cnc cutting machine near me

5 · best metal cutting cnc machine

6 · affordable metal cutter router

7 · affordable cnc machine for metal

What Is 7-Axis CNC Machining? 7 axis machining is a complete setup on its own and can manufacture complex parts without having to transfer them to another machine. When the part drops off, it is most often complete.

industrial metal laser cutting machine

The real difference between now and 5 years ago was, I learned to work with metal on manual milling machines and lathes and above all I had the right tools to design a machine. This .

I decided to put my engineering background to the test, and build my own CNC .Make Your Own DIY CNC: This instructable outlines the assembly process of my .With the right tools, materials, and know-how, anyone can build a custom CNC mill that can cut metal with precision and efficiency. In this guide, we'll walk you through the process of building .

sheet metal distributors

hobby cnc machine for metal

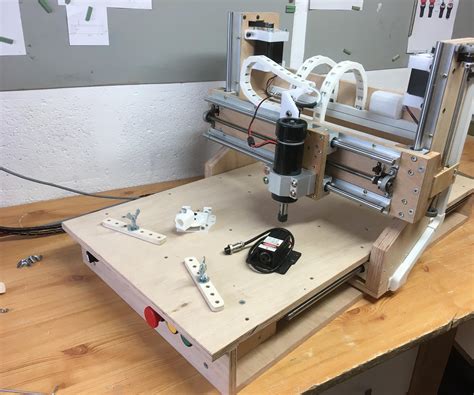

My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill.

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes .In this blog post, we will explore the process of building your own CNC machine for metal cutting, step-by-step. From selecting the right components to assembling and programming, this .The real difference between now and 5 years ago was, I learned to work with metal on manual milling machines and lathes and above all I had the right tools to design a machine. This Instructable will show you how I built my CNC milling machine.With the right tools, materials, and know-how, anyone can build a custom CNC mill that can cut metal with precision and efficiency. In this guide, we'll walk you through the process of building your own CNC milling machine from scratch.

My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill.

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.In this blog post, we will explore the process of building your own CNC machine for metal cutting, step-by-step. From selecting the right components to assembling and programming, this comprehensive guide will provide all the information you need to embark on your DIY CNC machine project. 1. Understanding the Basics of CNC:\Make Your Own DIY CNC: This instructable outlines the assembly process of my 2nd generation CNC machine which I designed to be simple to build and quiet enough to be apartment friendly. I have included example projects that I have made in the first two weeks of using the .

IndyMill is an open source DIY CNC machine that is mostly made out of metal. It was designed with simplicity and minimalism in mind! This project is not aiming to be the most heavy duty CNC machine out there, it is meant to be easy and inexpensive to build so that anyone can get a hand on precise CNC machining in many materials including metal. Are you learning & researching on how to make your own CNC kits for beginners? Review this DIY guide on how to build a CNC machine step by step from scratch.In this post, we'll walk you through the steps required to build your own DIY metal cutting CNC machine, including the materials you'll need, the tools required, and the software and electronics needed to control the machine. Materials: Frame materials (such as extruded aluminum)

sheet metal drawing auto part manufacturers

Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing?

The real difference between now and 5 years ago was, I learned to work with metal on manual milling machines and lathes and above all I had the right tools to design a machine. This Instructable will show you how I built my CNC milling machine.

With the right tools, materials, and know-how, anyone can build a custom CNC mill that can cut metal with precision and efficiency. In this guide, we'll walk you through the process of building your own CNC milling machine from scratch.

My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.In this blog post, we will explore the process of building your own CNC machine for metal cutting, step-by-step. From selecting the right components to assembling and programming, this comprehensive guide will provide all the information you need to embark on your DIY CNC machine project. 1. Understanding the Basics of CNC:\Make Your Own DIY CNC: This instructable outlines the assembly process of my 2nd generation CNC machine which I designed to be simple to build and quiet enough to be apartment friendly. I have included example projects that I have made in the first two weeks of using the .

IndyMill is an open source DIY CNC machine that is mostly made out of metal. It was designed with simplicity and minimalism in mind! This project is not aiming to be the most heavy duty CNC machine out there, it is meant to be easy and inexpensive to build so that anyone can get a hand on precise CNC machining in many materials including metal. Are you learning & researching on how to make your own CNC kits for beginners? Review this DIY guide on how to build a CNC machine step by step from scratch.

In this post, we'll walk you through the steps required to build your own DIY metal cutting CNC machine, including the materials you'll need, the tools required, and the software and electronics needed to control the machine. Materials: Frame materials (such as extruded aluminum)

cnc metal cutting machine price

Patch bays, aka junction boxes, simplify your setup by consolidating all your connections in one spot on your board. Patch bays can also save wear and tear on your pedals. We load our patch bays with high quality Neutrik, Switchcraft, or Lumberg jacks.

build a metal cutting cnc machine|cnc metal cutting machine price