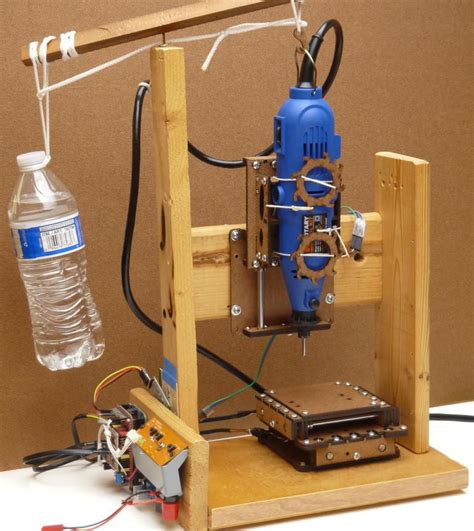

build a mini cnc machine for $45 Built mostly from laser-cut hardboard and a screwdriver, Minamil is a three-axis CNC device that can mill fine-pitch PCBs and comes to about $15 per axis. The design is . Electrical code requires that all junctions be accessible in a box, so you definitely need one here. You have two choices (that I know of at least): cut a large hole .

0 · Show HN: I built a CNC

1 · Minimal Mill: The Minamil

2 · Mini Desktop CNC Machine Build!

3 · Minamil: A Three

4 · How Much Does a CNC Machine Cost?

5 · FoxAlien

6 · CNC Machine From PC Parts

7 · Building a CNC router/mill for aluminum and light steel

8 · Build a mini cnc machine for $45

9 · Amazon.com: Mini Cnc Machine

A concrete distribution box is the traffic director of your septic system. It’s critical for managing the flow of wastewater from the septic tank to your drain field. This box ensures that effluent is evenly distributed across the drain field, preventing overloading and .

Built mostly from laser-cut hardboard and a screwdriver, Minamil is a three-axis CNC device that can mill fine-pitch PCBs and comes to about per axis. The design is .ARDUINO by Myself Mini-CNC (Plotter): Arduino Mini-CNC machine (working as a Plotter) Basic Operation and System Description: In This project I will guide you on how to easily build your . The Z axis is built using the read head hardware from a floppy drive. A 3-axis controller module from eBay drives the little machine, keeping . A bit about myself, I am 16 years old and for my senior project for high school, I plan on building a small CNC router. The CNC router will be used for; PCB's, wood work, plastics .

Building a CNC router/mill for aluminum and light steel, looking for design critique. I designed a small machine to mill aluminum and steel, and I designed it to be as cheap as . The latest is the Minamil, which uses a rotary tool and straps it to an economical frame in order to get a functional CNC mill setup working. This project boasts impressively low costs at around.

I just finished my latest project, building a CNC-machine from scratch using an Arduino Uno, GRBL and 40x 3d-printed parts. It’s able to mill wood and aluminium, up to ~20mm thick. As .The official FoxAlien website - A trusted vendor for CNC Router, CNC Router Bits, CNC Accessories, Laser Engraving Machine & DIY projects for any hobbyist. Visit to find out why thousands of makers love our products.

Show HN: I built a CNC

Discover the true cost of CNC machines. From entry-level to high-end models, find out the prices and factors that influence them. Get informed now!RATTMMOTOR CNC 1610-PRO CNC Wood Router Machine Kit, 3 Axis GRBL Control DIY Mini CNC Milling Engraver Engraving Machine with CNC Offline Controller for .Built mostly from laser-cut hardboard and a screwdriver, Minamil is a three-axis CNC device that can mill fine-pitch PCBs and comes to about per axis. The design is intended as a DIY project made from ready-to-assemble components and simple tools.

ARDUINO by Myself Mini-CNC (Plotter): Arduino Mini-CNC machine (working as a Plotter) Basic Operation and System Description: In This project I will guide you on how to easily build your own Mini-CNC machine and with a low cost (using arduino and scraped old DVD/CD drivers).

The Z axis is built using the read head hardware from a floppy drive. A 3-axis controller module from eBay drives the little machine, keeping the cost quite low at around . A bit about myself, I am 16 years old and for my senior project for high school, I plan on building a small CNC router. The CNC router will be used for; PCB's, wood work, plastics and (hopefully) Aluminium. Building a CNC router/mill for aluminum and light steel, looking for design critique. I designed a small machine to mill aluminum and steel, and I designed it to be as cheap as possible. T8 leadscrews, SBR12 fully supported linear rods, nema17 steppers. The latest is the Minamil, which uses a rotary tool and straps it to an economical frame in order to get a functional CNC mill setup working. This project boasts impressively low costs at around.

I just finished my latest project, building a CNC-machine from scratch using an Arduino Uno, GRBL and 40x 3d-printed parts. It’s able to mill wood and aluminium, up to ~20mm thick. As with all my other projects, I think they should be executed in the open where other people can learn from my mistakes and get inspired to build their own things!The official FoxAlien website - A trusted vendor for CNC Router, CNC Router Bits, CNC Accessories, Laser Engraving Machine & DIY projects for any hobbyist. Visit to find out why thousands of makers love our products. Discover the true cost of CNC machines. From entry-level to high-end models, find out the prices and factors that influence them. Get informed now!

My background is larger, metal cutting/grinding CNC machine tools, so that is my basis of comparison for all these small scale CNC machines. The more you look at the machine and its design, the more you realize it isn't the typical pile of .Built mostly from laser-cut hardboard and a screwdriver, Minamil is a three-axis CNC device that can mill fine-pitch PCBs and comes to about per axis. The design is intended as a DIY project made from ready-to-assemble components and simple tools.ARDUINO by Myself Mini-CNC (Plotter): Arduino Mini-CNC machine (working as a Plotter) Basic Operation and System Description: In This project I will guide you on how to easily build your own Mini-CNC machine and with a low cost (using arduino and scraped old DVD/CD drivers).

The Z axis is built using the read head hardware from a floppy drive. A 3-axis controller module from eBay drives the little machine, keeping the cost quite low at around .

A bit about myself, I am 16 years old and for my senior project for high school, I plan on building a small CNC router. The CNC router will be used for; PCB's, wood work, plastics and (hopefully) Aluminium.

Building a CNC router/mill for aluminum and light steel, looking for design critique. I designed a small machine to mill aluminum and steel, and I designed it to be as cheap as possible. T8 leadscrews, SBR12 fully supported linear rods, nema17 steppers. The latest is the Minamil, which uses a rotary tool and straps it to an economical frame in order to get a functional CNC mill setup working. This project boasts impressively low costs at around.I just finished my latest project, building a CNC-machine from scratch using an Arduino Uno, GRBL and 40x 3d-printed parts. It’s able to mill wood and aluminium, up to ~20mm thick. As with all my other projects, I think they should be executed in the open where other people can learn from my mistakes and get inspired to build their own things!

The official FoxAlien website - A trusted vendor for CNC Router, CNC Router Bits, CNC Accessories, Laser Engraving Machine & DIY projects for any hobbyist. Visit to find out why thousands of makers love our products. Discover the true cost of CNC machines. From entry-level to high-end models, find out the prices and factors that influence them. Get informed now!

Minimal Mill: The Minamil

stainless steel knock box

Mini Desktop CNC Machine Build!

Drilling a pilot hole and need to know what drill bit size to use? Reference are charts for all types of self-tapping screws, including AB, B, A, and 25.

build a mini cnc machine for $45|Minimal Mill: The Minamil