design guidelines for sheet metal parts Whereas manufacturers provide sheet metal materials in gauges. We will keep . $5.99

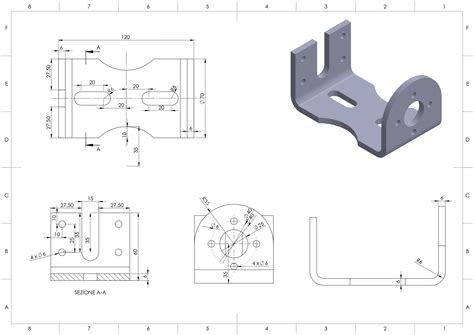

0 · sheet metal practice drawings pdf

1 · sheet metal pattern layout methods

2 · sheet metal layout techniques

3 · sheet metal design guideline pdf

4 · sheet metal design calculations pdf

5 · sheet metal calculations pdf

6 · sheet metal bending guide pdf

7 · basics in sheet metal design

Key Market Trends: The widespread adoption of computer numerical control (CNC) machines for precision and efficiency represents key trends in the market. There is also a shift toward automated and smart machinery that integrates (IoT) capabilities to .

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

K Factor in sheet metal bending is a constant used to calculate sheet metal .Whereas manufacturers provide sheet metal materials in gauges. We will keep .

These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Basic Principles

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also .Sheet metal DFM - design guidelines for formed and punched parts A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s .

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. In this guide, we delve into the principles of sheet metal design, provide technical insights, and share essential guidelines to help you navigate the world of sheet metal fabrication with confidence. Let’s get started! 1. Basic on .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can .Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Basic Principles

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability.

sheet metal practice drawings pdf

Sheet metal DFM - design guidelines for formed and punched parts A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. In this guide, we delve into the principles of sheet metal design, provide technical insights, and share essential guidelines to help you navigate the world of sheet metal fabrication with confidence. Let’s get started! 1. Basic on Sheet .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

best cnc router machine 5axis

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief are possible but require high-cost tooling.

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

best cnc stone carving machine

sheet metal pattern layout methods

These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Basic Principles In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability.

Sheet metal DFM - design guidelines for formed and punched parts A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job.

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. In this guide, we delve into the principles of sheet metal design, provide technical insights, and share essential guidelines to help you navigate the world of sheet metal fabrication with confidence. Let’s get started! 1. Basic on Sheet .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.

sheet metal layout techniques

Engineered wood, or composite wood, is any type of wood fiber, particle, or strand material held together with an adhesive or binding agent. Although some of these materials are easier to machine than solid woods, the .

design guidelines for sheet metal parts|sheet metal design calculations pdf