cnc machine principle Computer Numerical Control (CNC) machining is a manufacturing process where computerized controls and machine tools remove layers of material from a workpiece to . The supply plenum is an air distribution box. It’s attached directly to the supply outlet of the HVAC equipment–that is, the outlet that releases chilled or heated air into your home. The air ducts that distribute the air into the .

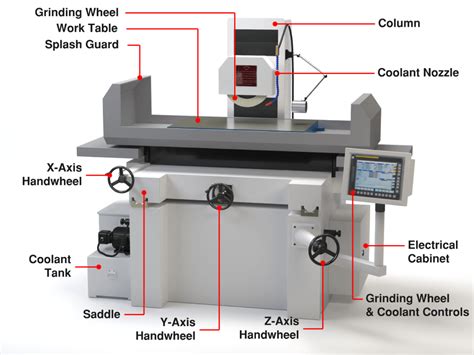

0 · main parts of cnc machine

1 · main components of cnc machine

2 · how to cnc machining work

3 · explain working of cnc machine

4 · explain Mcu in cnc

5 · cnc programming for beginners pdf

6 · cnc machine parts diagram

7 · cnc machine basic knowledge pdf

Nema Rating Height Width Depth Price Product Details; Floor Mount w/Leg Kit .

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the . CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and .The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages .

Computer Numerical Control (CNC) machining is a manufacturing process where computerized controls and machine tools remove layers of material from a workpiece to . CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .

CNC machining is a computer-controlled subtractive manufacturing process. It uses rotating cutting tools to remove material from a workpiece to produce a custom-designed part. The basic components of a .CNC machines use digital instructions (such as G-Code or M-Codes) to move and tool and workpiece in a CNC machine. For machining, the Operator firstly loads digital instructions (CNC Program) and fixes the workpiece in the machine.CNC machining is an advanced machining method, through the digital control technology of metal, non-metal and other materials cutting machining. Design parts: use CAD software to draw a three-dimensional model of the part. . In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method. CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and automation.The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

Computer Numerical Control (CNC) machining is a manufacturing process where computerized controls and machine tools remove layers of material from a workpiece to produce custom-designed parts. At its core, CNC machining utilizes pre-programmed software and code to dictate the movement of factory tools and machinery.

main parts of cnc machine

main components of cnc machine

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1. CNC machining is a computer-controlled subtractive manufacturing process. It uses rotating cutting tools to remove material from a workpiece to produce a custom-designed part. The basic components of a CNC machine are the workpiece, cutting tools, tool holders, spindle, and bed.

CNC machines use digital instructions (such as G-Code or M-Codes) to move and tool and workpiece in a CNC machine. For machining, the Operator firstly loads digital instructions (CNC Program) and fixes the workpiece in the machine.

CNC machining is an advanced machining method, through the digital control technology of metal, non-metal and other materials cutting machining. Design parts: use CAD software to draw a three-dimensional model of the part. Generate the program: CAD model into a CAM software can recognize the data format, generate CNC machining program. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method.

CNC (Computer Numerical Control) machines are automated tools controlled by computers to execute precise machining operations. These represent a revolutionary advancement in the realm of manufacturing and automation.The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

Computer Numerical Control (CNC) machining is a manufacturing process where computerized controls and machine tools remove layers of material from a workpiece to produce custom-designed parts. At its core, CNC machining utilizes pre-programmed software and code to dictate the movement of factory tools and machinery. CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1. CNC machining is a computer-controlled subtractive manufacturing process. It uses rotating cutting tools to remove material from a workpiece to produce a custom-designed part. The basic components of a CNC machine are the workpiece, cutting tools, tool holders, spindle, and bed.

CNC machines use digital instructions (such as G-Code or M-Codes) to move and tool and workpiece in a CNC machine. For machining, the Operator firstly loads digital instructions (CNC Program) and fixes the workpiece in the machine.

how to cnc machining work

5 gang plastic old work electrical box

Crafted from durable pre-galvanized steel, these boxes are designed to house wiring devices such as switches or outlets. With RACO's Switch Electrical Boxes, convenience is key. The device mounting holes are pre-tapped to accept 6-32 .

cnc machine principle|cnc machine basic knowledge pdf