cnc homemade machine Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress . The fundamental goal of sheet metal forming procedures is to give the metal sheets particular geometrical modifications while preserving their structural integrity. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Learn about sheet metal here!

0 · make your own cnc mill

1 · make your own cnc machine

2 · home built cnc milling machine

3 · do it yourself cnc machine

4 · diy cnc machine for woodworking

5 · building my own cnc machine

6 · build your own cnc mill

7 · build your own cnc machine

Currently, there are three common types of steel box trusses widely used in construction: steel box trusses for tiled roofs, steel lattice roof trusses, and galvanized steel box trusses. 1.1. Steel box trusses for tiled roofs. This structure follows the traditional lean-to-tile supporting structure, a proven principle in the tile support .

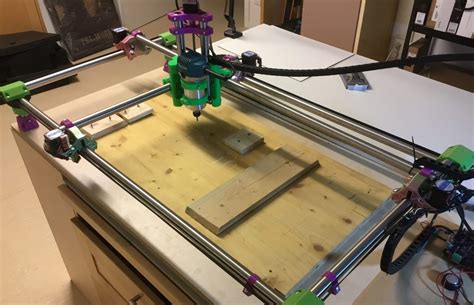

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes .Most homemade CNC routers use a standard woodworking router or trim .

This Instructable will show you how I built my CNC milling machine. I know a lot of .Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

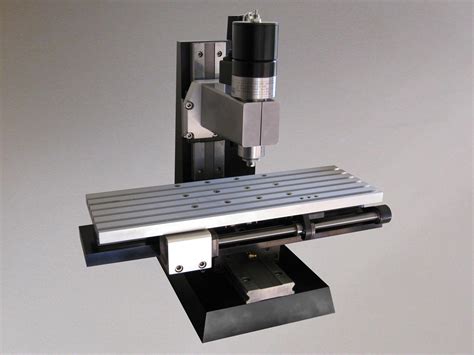

How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, . Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you .

A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated . Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY . In this video, I'll show you how I built this awesome CNC router without having access to high end tools, and what it's capable of. I decided to keep the video relatively short, .

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.

make your own cnc mill

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing?

A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated and follow digital designs.

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine. What is a CNC Machine? In this video, I'll show you how I built this awesome CNC router without having access to high end tools, and what it's capable of. I decided to keep the video relatively short, but will be happy.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing?A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated and follow digital designs.

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine. What is a CNC Machine?

make your own cnc machine

CNC Machining is a very broad subject and there are many ways to do most things. Covering all options would fill volumes and isbeyond the scope of any one book or course. The goal of this course is not to turn and engineer into a journeyman machinist. Rather, it is to show how to use CNC to make common types of

cnc homemade machine|building my own cnc machine